A kind of carbon thin film, activated carbon thin film and its preparation method and supercapacitor

A technology of supercapacitor and carbon film, which is applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, nanotechnology for materials and surface science, etc. It can solve the poor mechanical flexibility of porous bulk materials, the limitation of capacitor flexibility, Low energy storage density and other issues, to achieve good mechanical flexibility, increase energy density, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A method for preparing and activating a carbon thin film, comprising the steps of:

[0054] (1) Sandwich fresh petals between two graphite plates and heat and dry them at 110°C on a heating table;

[0055] (2) Place the dried petals in a tube furnace and heat at 800° C. for 4 hours under the protection of nitrogen, with a nitrogen flow rate of 50 sccm, to obtain a carbonized product;

[0056] (3) Soak the carbonized product in 1M nitric acid at 25°C for 96 hours to remove inorganic particles to obtain a carbon film;

[0057] (4) Place the carbon film in a tube furnace and heat it in air at 280° C. for 4 hours to obtain an activated carbon film.

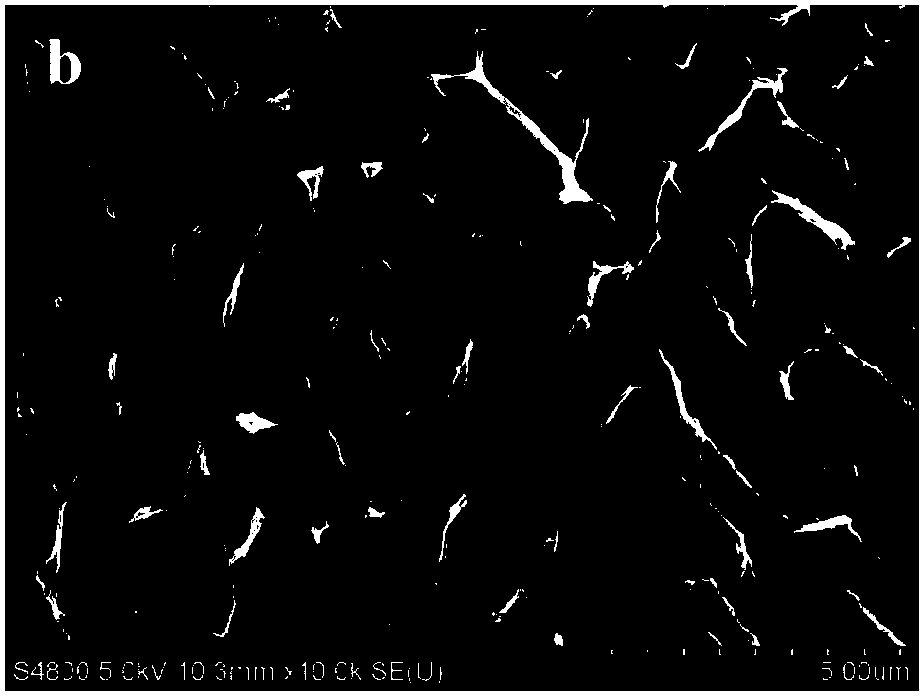

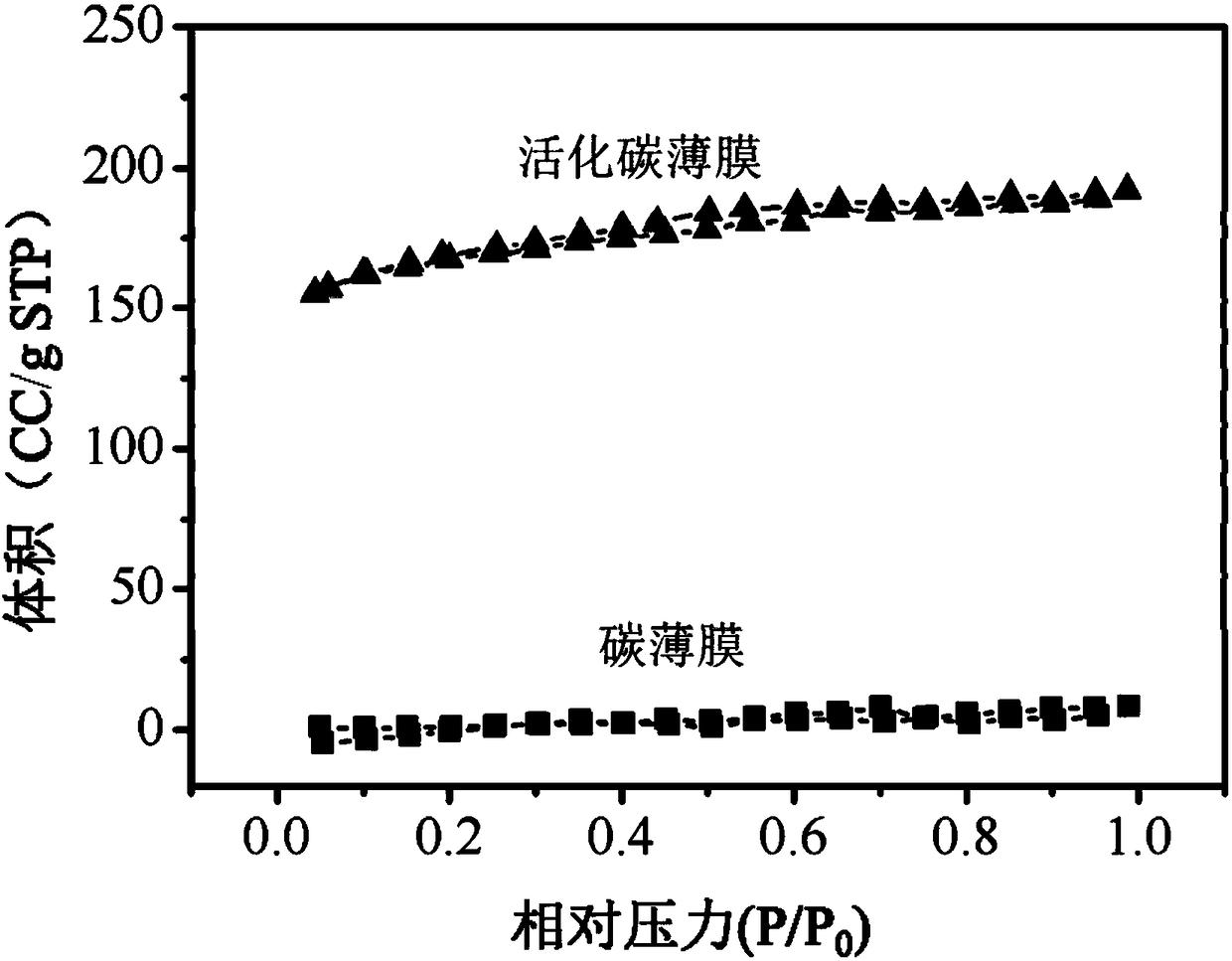

[0058] The activated carbon film that step (4) obtains is a self-supporting structure, and its size is 60-80mm 2 , observed by a scanning electron microscope (model Hitachi S4800FESEM), the prepared activated carbon film thickness is 2-50 μm, the surface contains a large number of wrinkled structures, and the ridge height of ...

Embodiment 2

[0060] A method for preparing and activating a carbon thin film, comprising the steps of:

[0061] (1) Sandwich fresh petals between two graphite plates and heat and dry them at 110°C on a heating table;

[0062] (2) Place the dried petals in a tube furnace and heat them at 1000° C. for 1 h under the protection of argon, with an argon flow rate of 100 sccm, to obtain a carbonized product;

[0063] (3) Soak the carbonized product in 4M hydrochloric acid at 25°C for 48 hours to remove the inorganic particles on the surface of the carbon film;

[0064] (4) Place the carbon film in a tube furnace and heat it in air at 300° C. for 1 h to obtain an activated carbon film.

[0065] The activated carbon film obtained in step (4) is a self-supporting structure, such as Figure 1-a As shown, its size is 50-70mm 2 , observed by a scanning electron microscope (model Hitachi S4800FESEM), the prepared activated carbon film thickness is 2-50 μ m, the surface contains a large number of wrink...

Embodiment 3

[0067] A method for preparing and activating a carbon thin film, comprising the steps of:

[0068] (1) Sandwich fresh petals between two graphite plates and heat and dry them at 110°C on a heating table;

[0069] (2) Place the dried petals in a tube furnace and heat them at 1200° C. for 30 minutes under the protection of argon, and the argon flow rate is 2000 sccm to obtain a carbonized product;

[0070] (3) Soak the carbonized product in 6M sulfuric acid at 25°C for 24 hours to remove the inorganic particles on the surface of the carbon film to obtain a carbon film;

[0071] (4) Place the carbon film in a tube furnace and heat it in air at 400° C. for 2 hours to obtain an activated carbon film.

[0072] The activated carbon film that step (4) obtains is self-supporting structure, and its size is 40-60mm 2 , observed by scanning electron microscope (model Hitachi S4800FESEM), the thickness of the prepared activated carbon film is 2-50 μm, the surface contains a large number ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com