Phosphomolybdic acid-polymer composite conductive hydrogel and its preparation method and application in all-solid flexible supercapacitors

A conductive hydrogel and supercapacitor technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problem of inhibiting the effective use of inherent capacitance, achieve excellent toughness and processability, and have broad application prospects. The effect of strong hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

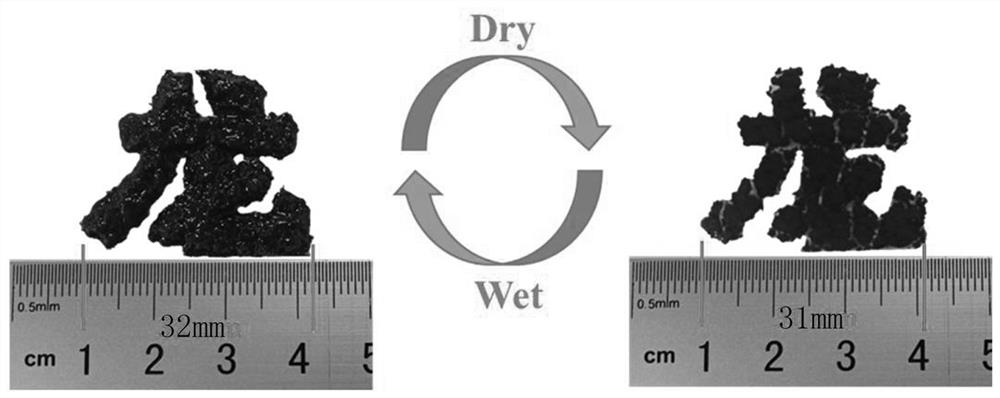

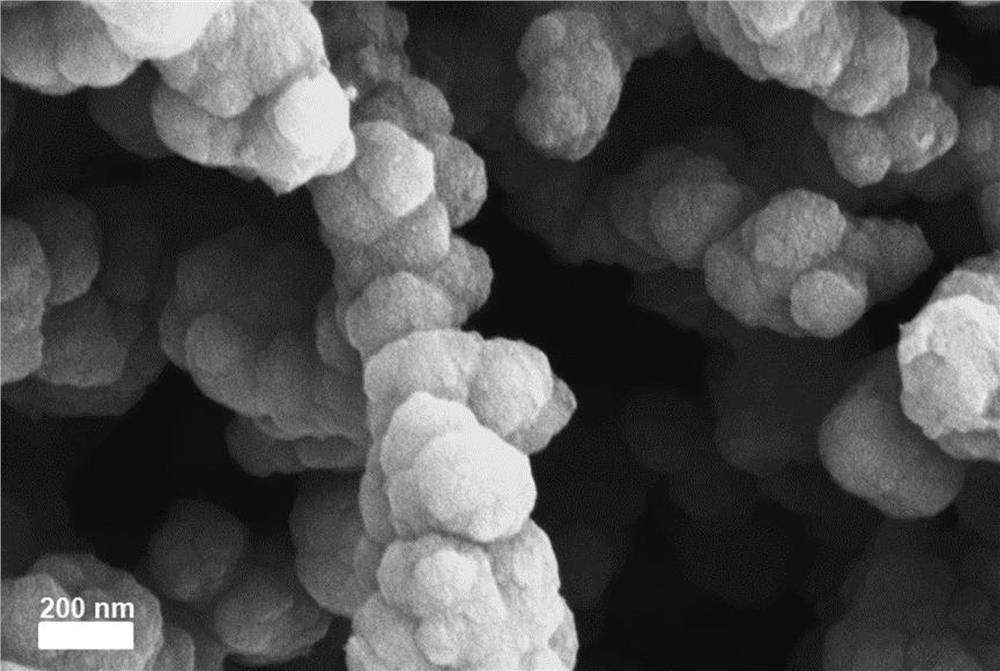

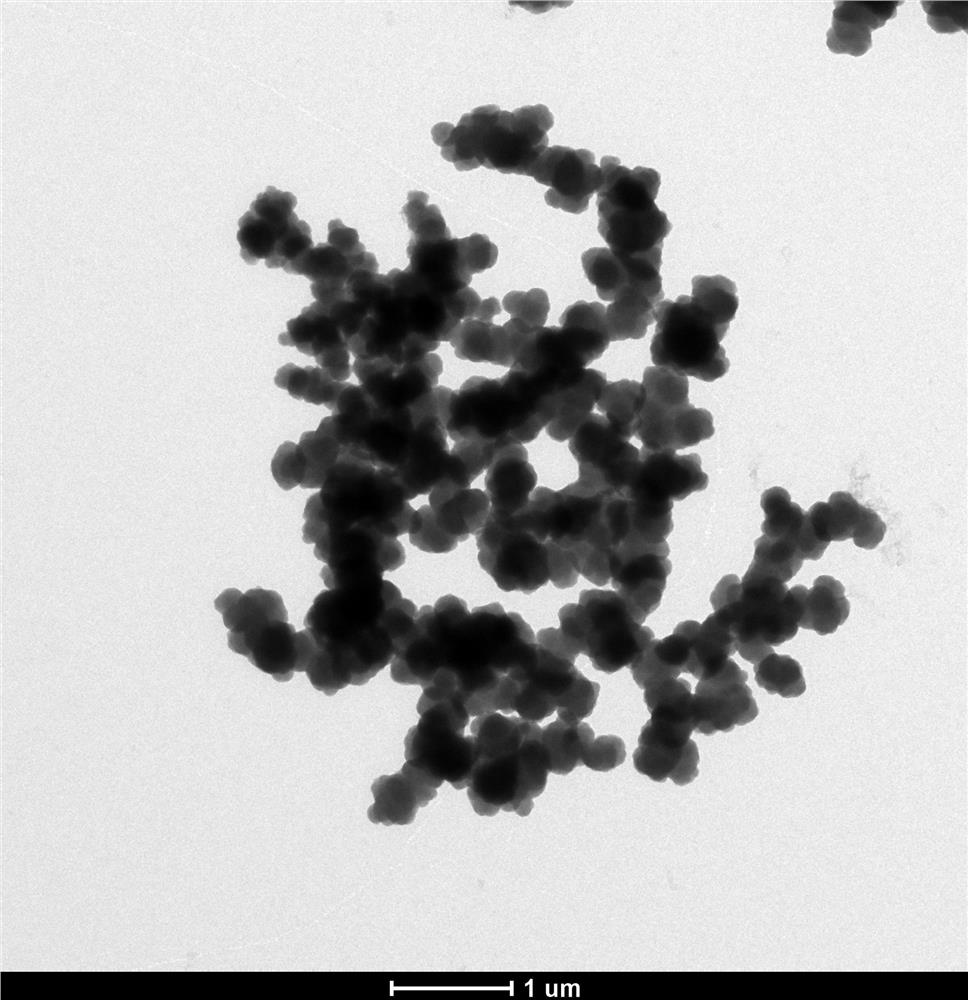

[0036] Example 1: A phosphomolybdic acid / polymer composite conductive hydrogel, in a one-step in-situ polymerization process, through electrostatic self-assembly and physical Formed by adsorption, phosphomolybdic acid nanoparticles are uniformly anchored or embedded on the surface or inside of the interconnected 3D grid structure polymer conductive hydrogel.

[0037] The preparation method is as follows: 21-336 microliters of pyrrole (Py) monomer is dissolved in 0.25-4 mL of isopropanol, labeled as liquid A. Then weigh 0.08 g PMo 12 Dissolve the powder in 1 mL of deionized water and sonicate for 20 min, then add 0.05-0.8 g of anhydrous ferric chloride powder, continue to sonicate for 20 min, then add 0.06-0.096 g of TCPP cross-linking agent and stir vigorously until uniformly dispersed, mark For liquid B. Both the prepared A and B liquids were placed in a 4°C refrigerator, and after 10-30 minutes in the refrigerator, the A liquid was quickly added to the B liquid, and a blac...

Embodiment 2

[0038] Example 2: The preparation method of a phosphomolybdic acid / polymer composite conductive hydrogel provided in this example is the same as that in Example 1, except that the monomer in this example is aniline.

Embodiment 3

[0039] Embodiment 3: A kind of phosphomolybdic acid / polymer composite conductive hydrogel provided in this embodiment, the preparation method is the same as the basic steps of embodiment 1, the difference is that the PMo in this embodiment 12 The mass of the powder is 0.32 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com