A self-supporting two-dimensional mxene@znmn 2 o 4 Preparation and Application of Composite Electrode Materials

A composite electrode and self-supporting technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of cumbersome preparation of electrode materials and difficulties in the preparation of template methods, achieve great practical value and scientific research value, save preparation costs, and be friendly water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

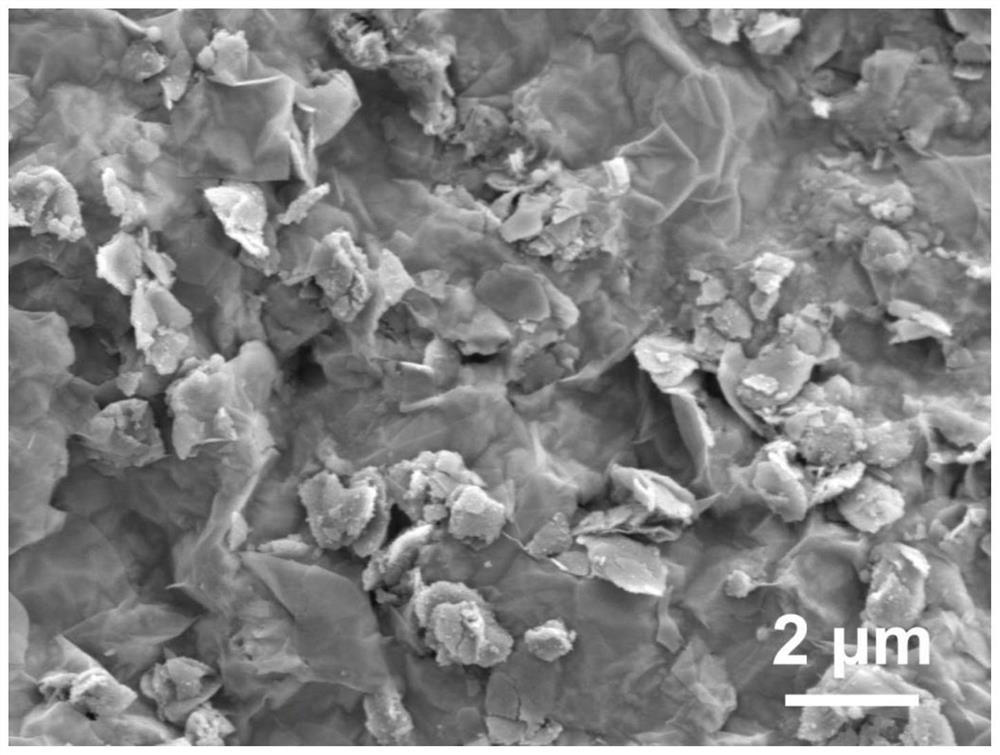

[0036] As introduced in the background technology, for the current two-dimensional ZnMn 2 o 4 Prepare difficult problems. Therefore, the present invention proposes a two-dimensional MXene and two-dimensional flake ZnMn 2 o 4 Material composite flexible self-supporting film and preparation method thereof, comprising:

[0037] Two-dimensional flake ZnMn 2 o 4 The preparation method of the present invention comprises compounding a zinc-based metal organic framework compound and a manganese-based metal organic framework compound at a ratio of 1:2 to obtain a bimetallic organic framework compound as a precursor, and heat treatment in an air atmosphere to obtain a two-dimensional Flake ZnMn 2 o 4 Material.

[0038] Further, the heating rate of the heat treatment is 1° / min~5° / min;

[0039] Further, the heat-holding temperature of the heat treatment is 350-550°C, and the holding time is 2 hours-10 hours;

[0040] To prepare a two-dimensional MXene colloidal solution, stir th...

Embodiment 1

[0058] Weigh 0.7846g of perylenetetracarboxylic dianhydride, dissolve in 125ml of 0.32g of sodium hydroxide solution, and stir at room temperature for half an hour to obtain A solution.

[0059] Weigh 0.244g of zinc acetate and 0.45g of manganese acetate and dissolve them in 225ml of deionized water, and stir for half an hour to obtain B solution.

[0060] Subsequently, solution A was added dropwise to solution B, and continued to stir for one hour to mix evenly, then put it into a high-temperature and high-pressure reactor, and kept it in a constant temperature oven at 100°C for 6 hours to obtain layered / accordion-shaped ZnMn 2 Bimetallic organic framework materials.

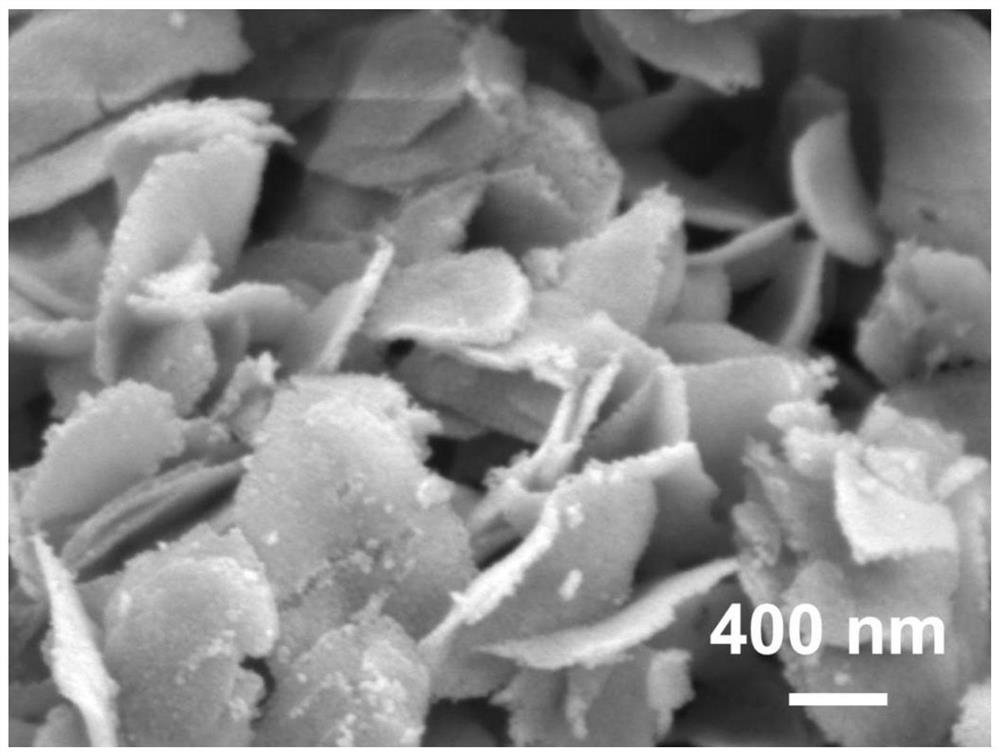

[0061] Then, the ZnMn 2 The bimetal organic framework material is heated to 500°C at a heating rate of 1-5°C / min, and kept at 500°C for 6 hours to obtain a two-dimensional sheet ZnMn 2 o 4 powder.

[0062] Select Ti in MAX phase 3 AlC 2 powder, stirred in a mixed solution of hydrochloric acid and lithium ...

Embodiment 2

[0070] MAX phase chooses V 2 AlC powder, etched with hydrochloric acid and potassium fluoride to remove the middle aluminum atomic layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com