Method and device for using crude hydrocyanic acid to continuously produce D, L-methionine

A technology for methionine and production device, which is applied in the field of continuous production of D,L-methionine, can solve the problems of increased production cost, low value, and increased production cost of D,L-methionine salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

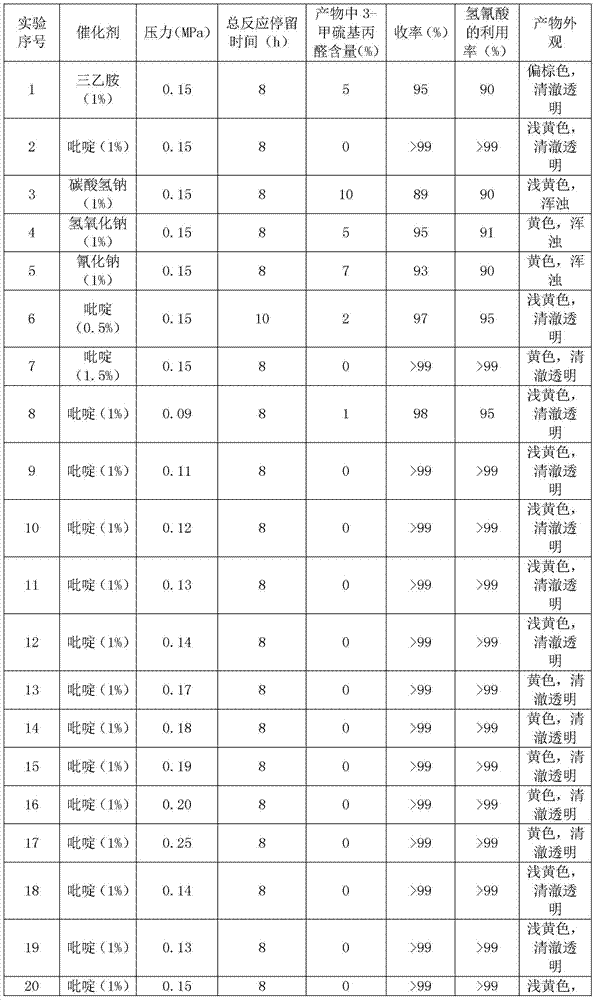

Examples

Embodiment

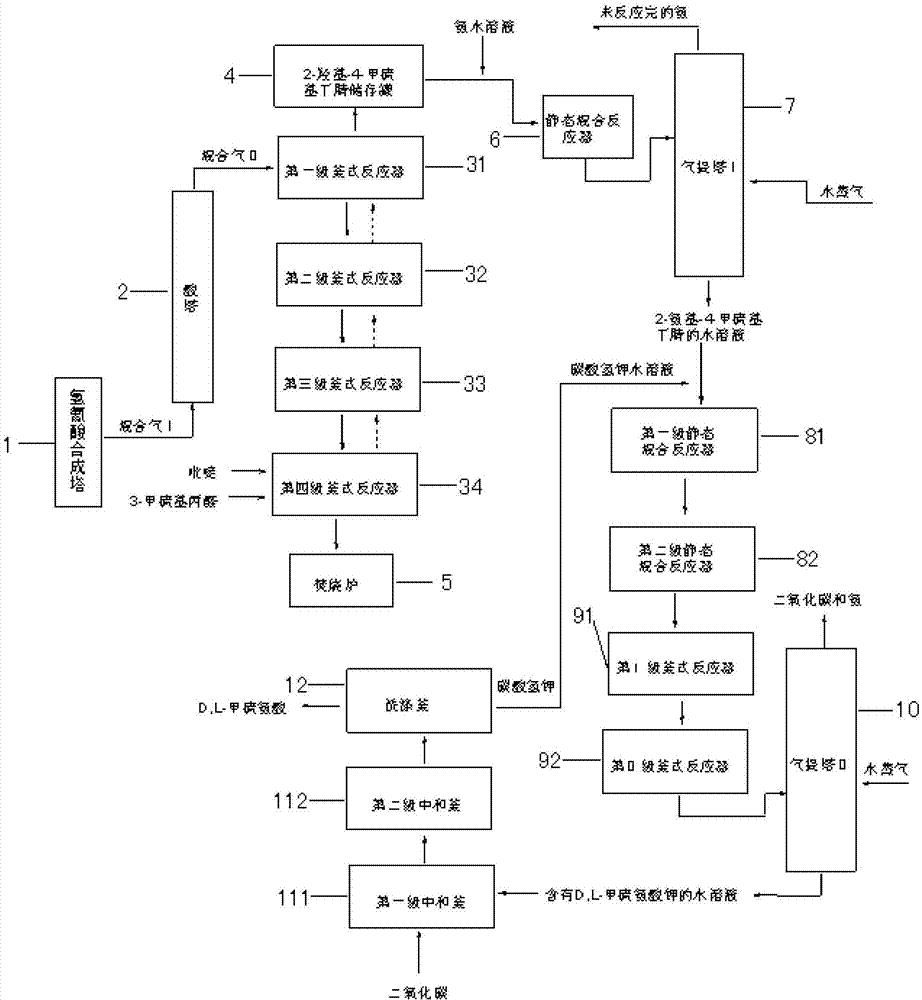

[0039] Such as figure 1 As shown, the device for producing D,L-methionine includes hydrocyanic acid synthesis tower 1, acid tower 2, four-stage series tank reactor, low temperature storage tank 4, incinerator 5, static mixing reactor I6, gas Stripping tower I7, static mixing reactor II8, tank reactor 9, gas stripping tower II10, neutralization tank 11 and washing tank 12; the gas outlet of the hydrocyanic acid synthesis tower 1 passes through the pipeline and the inlet of acid tower 2 The four-stage series tank reactor is equipped with pressure and temperature adjustment auxiliary devices, consisting of a first-stage tank reactor 31, a second-stage tank reactor 32, a third-stage tank reactor 33, and The four-stage tank reactor 34 is connected in series, and the adjacent reactors are connected by gas flow and logistics pipeline; the gas inlet of the first-stage tank reactor 31 and the gas outlet of the acid tower 2 are connected through the pipeline, and the first The discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com