Method and apparatus for producing silicon nitride or ferro silicon nitride by low pressure combustion

A technology of ferrosilicon nitride and low-pressure combustion, which is applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., and can solve problems such as inability to continue large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

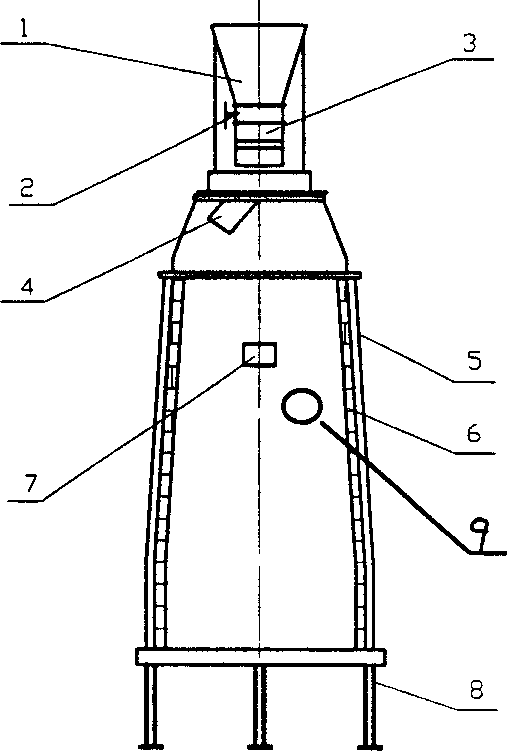

Image

Examples

Embodiment Construction

[0017] The silicon powder and silicon nitride powder are batched according to the ratio of 100:20, and then put into a ball mill to mix and grind, so that the particle size after grinding is -0.088mm, ≥90%. Pile coke and wood at the bottom of the vertical combustion synthesis reactor until it reaches the inside of the reaction vessel, and then ignite the wood and coke. When the inside of the reaction vessel reaches 1000°C, the nitrogen gas is preheated through the interlayer of the reaction vessel and then enters the reaction vessel. internal. At the same time, the batch material is evenly sprinkled into the reaction vessel through the gate valve, quantitative feeder, and distributor, where the combustion synthesis reaction is carried out. Falling into the bottom of the reaction vessel under the action of gravity, a β-type silicon nitride product with a honeycomb loose block structure is finally obtained, and the reaction product becomes a silicon nitride powder with a β-type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com