Bioreactor and sophorolipid continuous production method by using the same

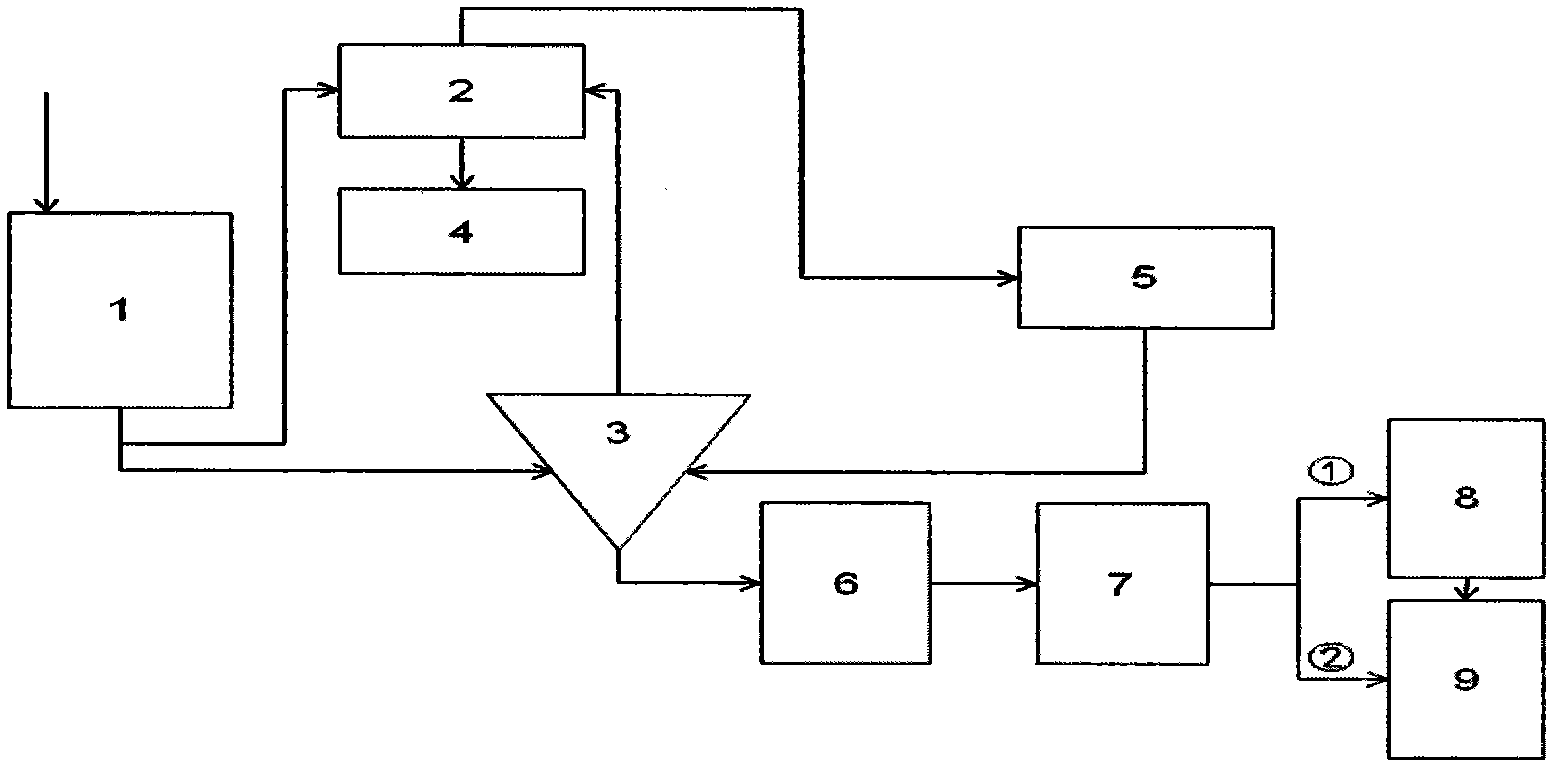

A technology of bioreactor and microbial fermentation biosurfactant, which is applied in the method of biological material sampling, bioreactor/fermenter combination, bioreactor/fermenter for specific purposes, etc., can solve the problem that there is no public sale of pure microbial fermentation biosurfactant. , high production costs, restrictions on sophorolipids, etc., to achieve the effects of easy equipment control, reduced separation costs, and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

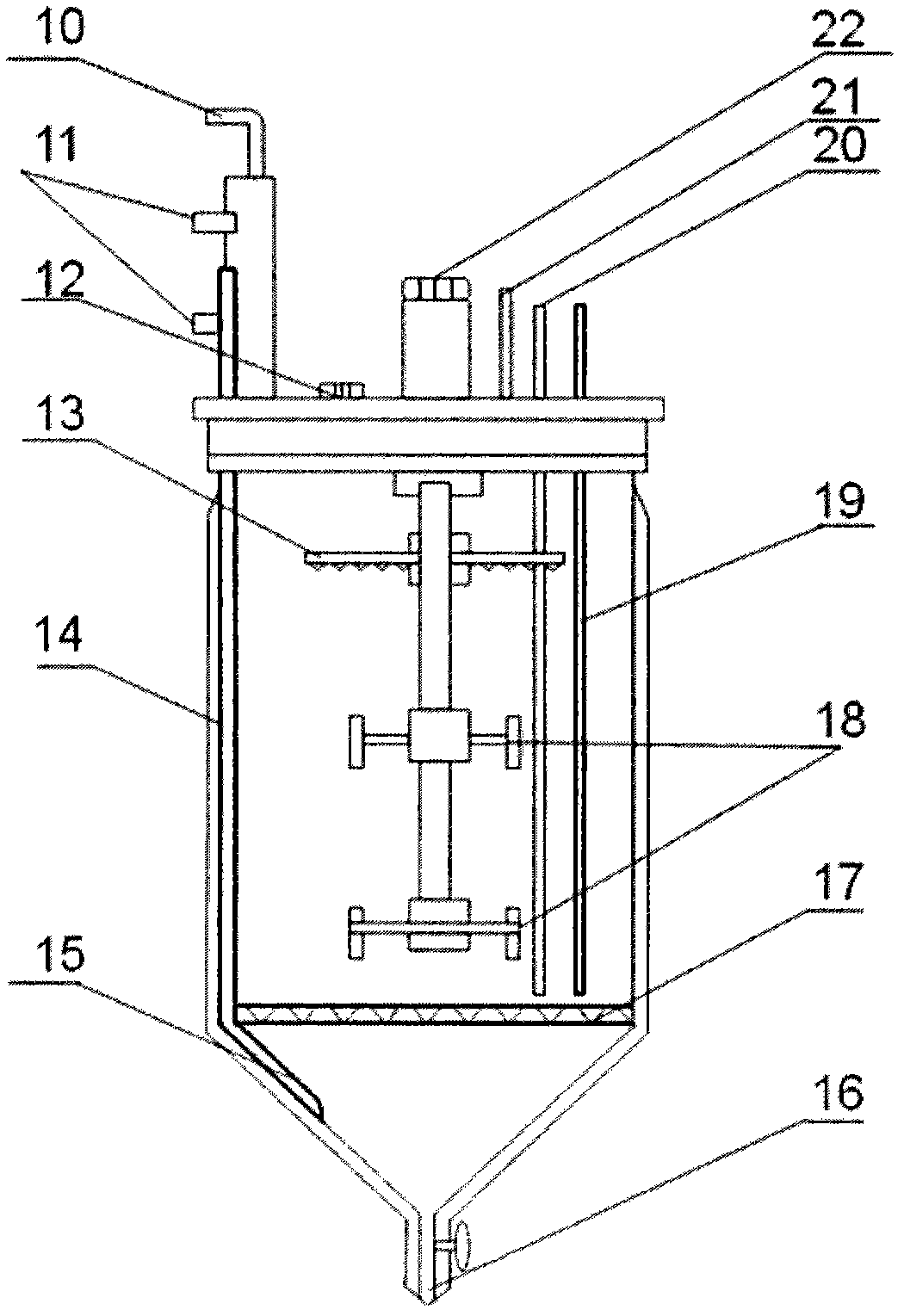

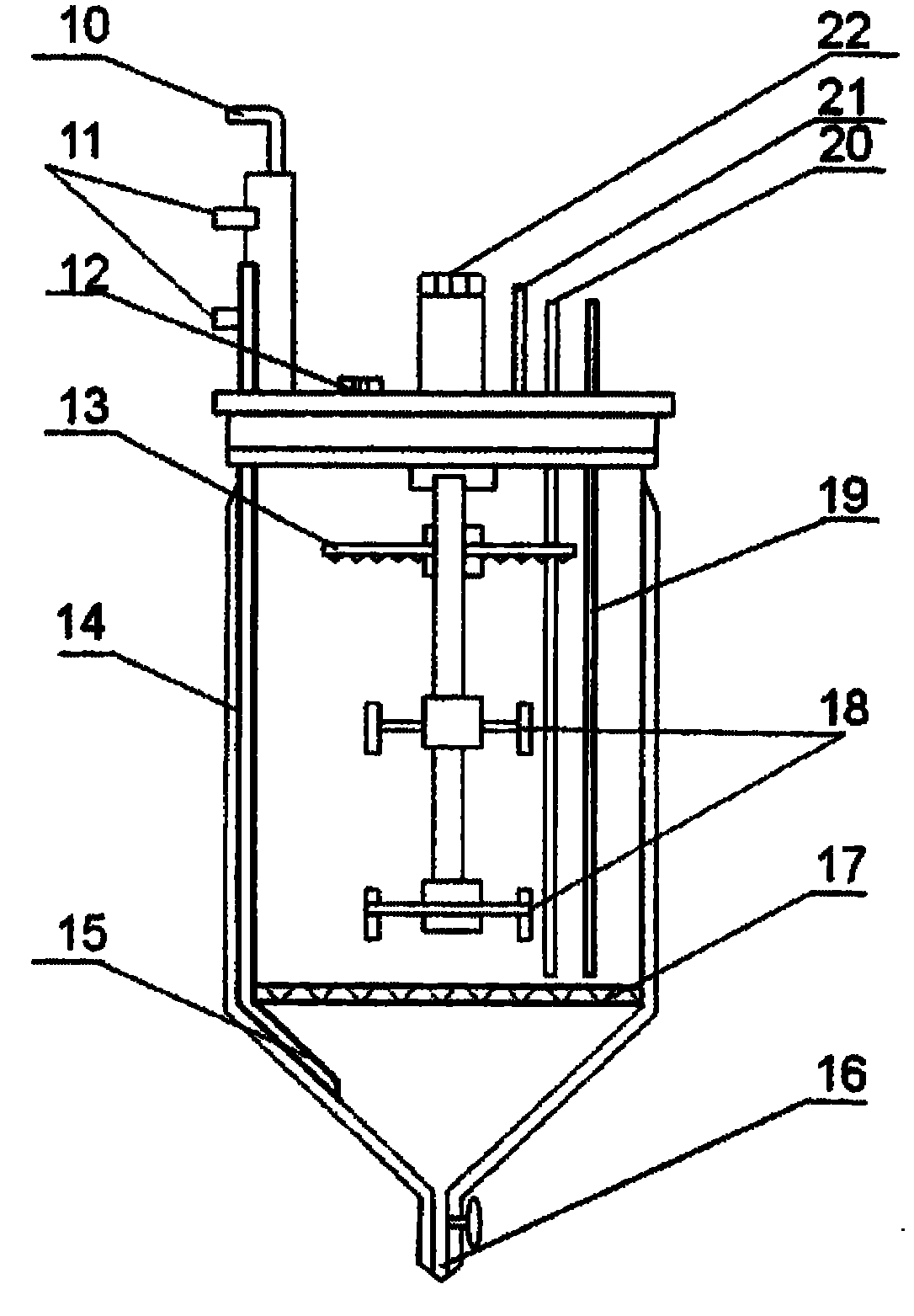

[0024] Taking the strain 1 whose sophorolipid yield was 90 g / L during batch fermentation as the production strain as an example.

[0025] Add 6L of sterilized fermentation medium into the device, and the components of the medium are glucose 130g / L, yeast powder 10g / L, and urea 1g / L. Add the cultured seed liquid through the inoculation port, the seed liquid is the bacterial cell enrichment liquid obtained by culturing the thalline through the seed medium at 30°C for 48 hours, the culture condition: the pH value is 6; the composition of the seed medium is : Glucose 100g / L, yeast powder 10g / L and urea 1g / L; then add rapeseed oil in batches at a rate of 50mL / d. Add rapeseed oil in batches at a high speed. 96 hours before the fermentation, the upper and lower tanks were ventilated with oxygen at the same time, and the rotating speed was controlled to keep the dissolved oxygen above 50%. Ferment until the aeration at the lower end stops for 96 hours, open the valve after 5 hours, ...

Embodiment 2

[0028] Take the strain 2 whose sophorolipid yield is 120g / L during batch fermentation as the production strain as an example.

[0029] Add 6L sterilized fermentation medium into the device, the medium components are glucose 150g / L, yeast powder 3g / L, peptone 0.7g / L, sodium citrate 5g / L, MgSO 7H O 4g / L, ( NH4)2SO42g / L, KH2PO41g / L, NaCl 0.1g / L, CaCl2·2H2O 0.1g / L. Add the cultured seed liquid through the inoculation port, the seed liquid is the bacterial cell enrichment liquid obtained by culturing the thalline through the seed medium at 30°C for 48 hours, the culture condition: the pH value is 6; the composition of the seed medium is : Glucose 100g / L, yeast powder 10g / L and urea 1g / L; then add rapeseed oil in batches at a rate of 80mL / d. 55 hours before the fermentation, the upper and lower tanks were ventilated with oxygen at the same time, and the rotating speed was controlled to keep the dissolved oxygen at a relatively high level. Ferment until the aeration at the lower en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com