Boron nitride aerogel phase-change film, and preparation method and application thereof

A boron nitride and aerogel technology, which is applied in the field of boron nitride aerogel phase change film and its preparation, can solve the problems of thermal discomfort, scalding, heat dissipation, etc., and achieves easy operation, low cost and low energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] An aspect of the embodiments of the present invention provides a method for preparing a boron nitride airgel phase change film, which includes:

[0046] A melamine borate-based material is provided, the melamine borate-based material comprising a host material and an additive, the host material comprising boric acid and melamine;

[0047] Applying pressure to the melamine borate-based material for pressure-induced assembly to prepare a melamine borate-based film;

[0048] Carrying out high-temperature pyrolysis treatment to the melamine borate-based film to prepare a boron nitride airgel film;

[0049] The boron nitride airgel film is filled with a phase change material in a molten filling manner to obtain a boron nitride airgel phase change film.

[0050] In some preferred embodiments, the additive includes any one or a combination of two or more of cyanuric acid, biuret, dimethylguanidine, triethylamine, etc., but is not limited thereto.

[0051] In some preferred e...

Embodiment 1

[0094] (a) Select a melamine borate-based material with a boric acid:melamine mass ratio of 1:1 and a cyanuric acid content of 0.01 wt%.

[0095] (b) cutting the melamine borate-based material in step (a) to obtain a melamine borate-based sheet with a thickness of 3 mm.

[0096] (c) Pressure assembling the melamine borate-based sheet in step (b) under a pressure of 10 MPa to obtain a melamine borate-based film.

[0097](d) annealing the melamine borate-based film in step (c) at 600° C. for 24 hours under an ammonia atmosphere to obtain a boron nitride airgel film.

[0098] (e) Immerse the boron nitride airgel film in step (d) in molten paraffin, let it stand in an oven at 100° C. for 1 hour, take it out, cool and solidify, and obtain a boron nitride phase-change composite film.

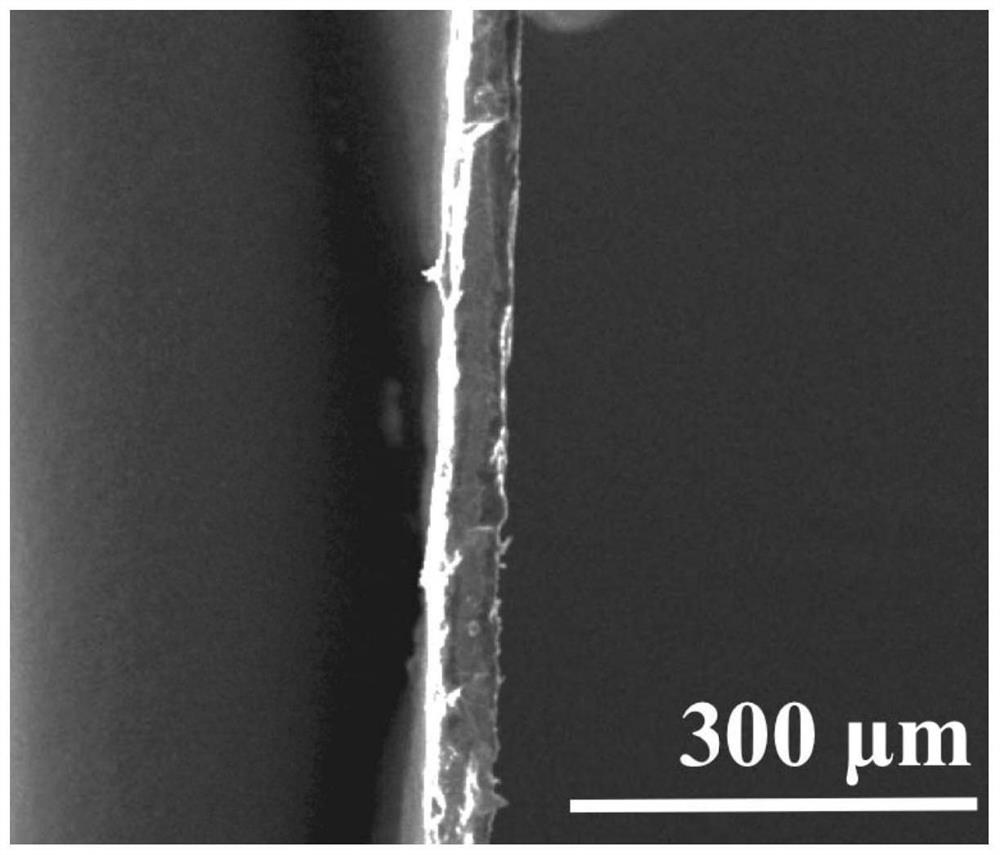

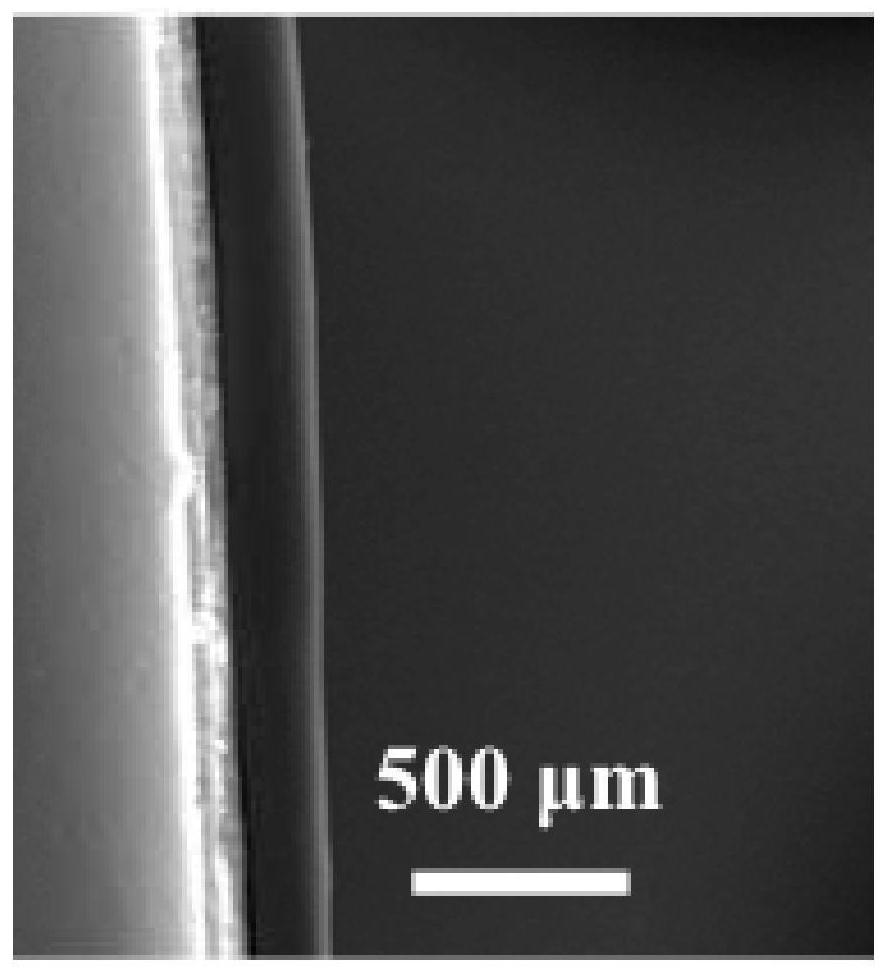

[0099] figure 1 This is the SEM photo of the cross-section of the boron nitride airgel phase-change film obtained in this example. Please refer to Table 1 for the structure and performance parameter...

Embodiment 2

[0101] (a) Select a melamine borate-based material with a boric acid:melamine mass ratio of 1:10 and a triethylamine content of 50 wt%.

[0102] (b) cutting the melamine borate-based material in step a) to obtain a melamine borate-based sheet with a thickness of 80 μm.

[0103] (c) Pressure assembling the melamine borate-based sheet in step b) under a pressure of 10 kPa to obtain a melamine borate-based film.

[0104] (d) annealing the melamine borate-based thin film in step c) at 1500° C. for 3 h in an argon / ammonia atmosphere to obtain a boron nitride airgel thin film.

[0105] (e) Immerse the boron nitride airgel film in step (d) in molten polyethylene glycol, let it stand in an oven at 150°C for 1 min, take it out, cool and solidify, and obtain a boron nitride phase-change composite film .

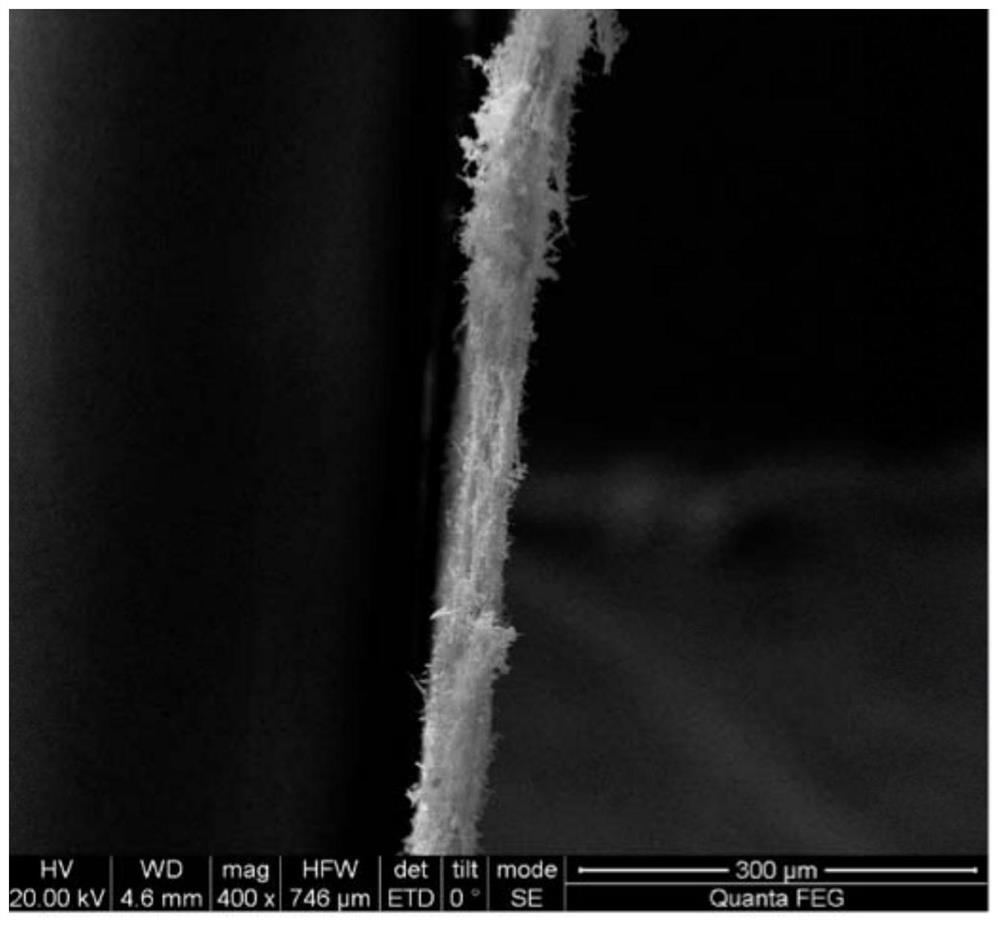

[0106] figure 2 This is the SEM photo of the cross-section of the boron nitride airgel phase-change film obtained in this example. Please refer to Table 1 for the structure and per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com