Integrated bag-type dust removal and fluidized adsorption device

An adsorption device and fluidized technology, which is applied in the field of integrated bag dust removal and fluidized adsorption device, can solve problems such as troublesome operation, achieve stable operation, fast mass and heat transfer rate, and facilitate regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

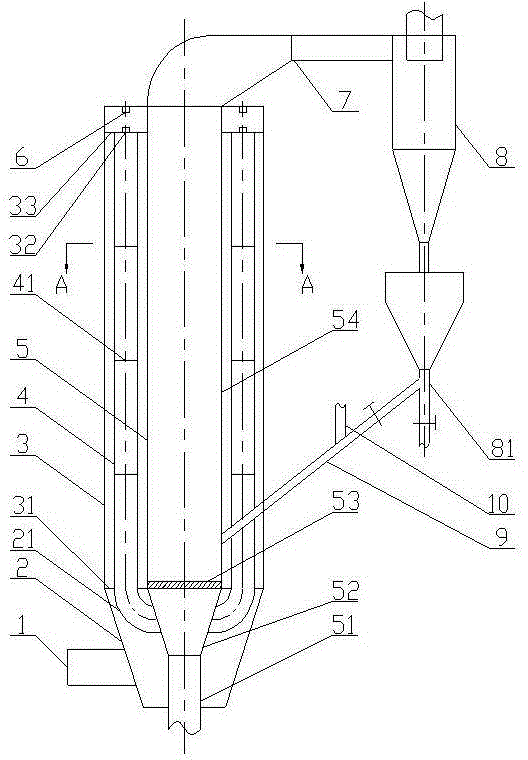

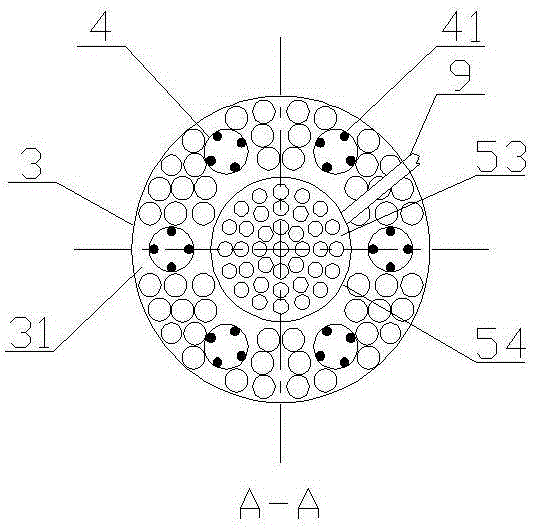

[0013] like figure 1 and figure 2 As shown, a device integrating bag dust removal and fluidized adsorption includes ash bin 2, box body 3, and ash cleaning device from bottom to top. The box body 3 is cylindrical, and the box body 3 is divided into a sub-chamber, and several filter bags 4 for dust removal are arranged in the sub-chamber. A gas-solid separator 8 is connected to the outside of the box body 3, and the gas-solid separator 8 is a cyclone separator. The flue gas inlet 1 is installed on the ash bin 2 , and the flue gas enters the ash bin 2 through the flue gas inlet 1 , flows through the perforated plate 31 and enters the box body 3 . The perforated plate 31 is provided with a plurality of round holes for the purpose of making the amount of flue gas treated by each vertically installed filter bag 4 equal, and the 6 filter bags 4 are evenly distributed along the cross section of the box body 3, and the dust filter adopts an external filter type. The filter bag 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com