A microwave-fluidized roasting device for processing complex refractory iron ore

A fluidized roasting and iron ore technology, applied in the field of mineral processing, can solve the problems of easy formation of rings, fine inlaid useful minerals, low iron ore grade, etc., and achieves sufficient gas-solid contact and improved selection index. , the effect of efficient comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

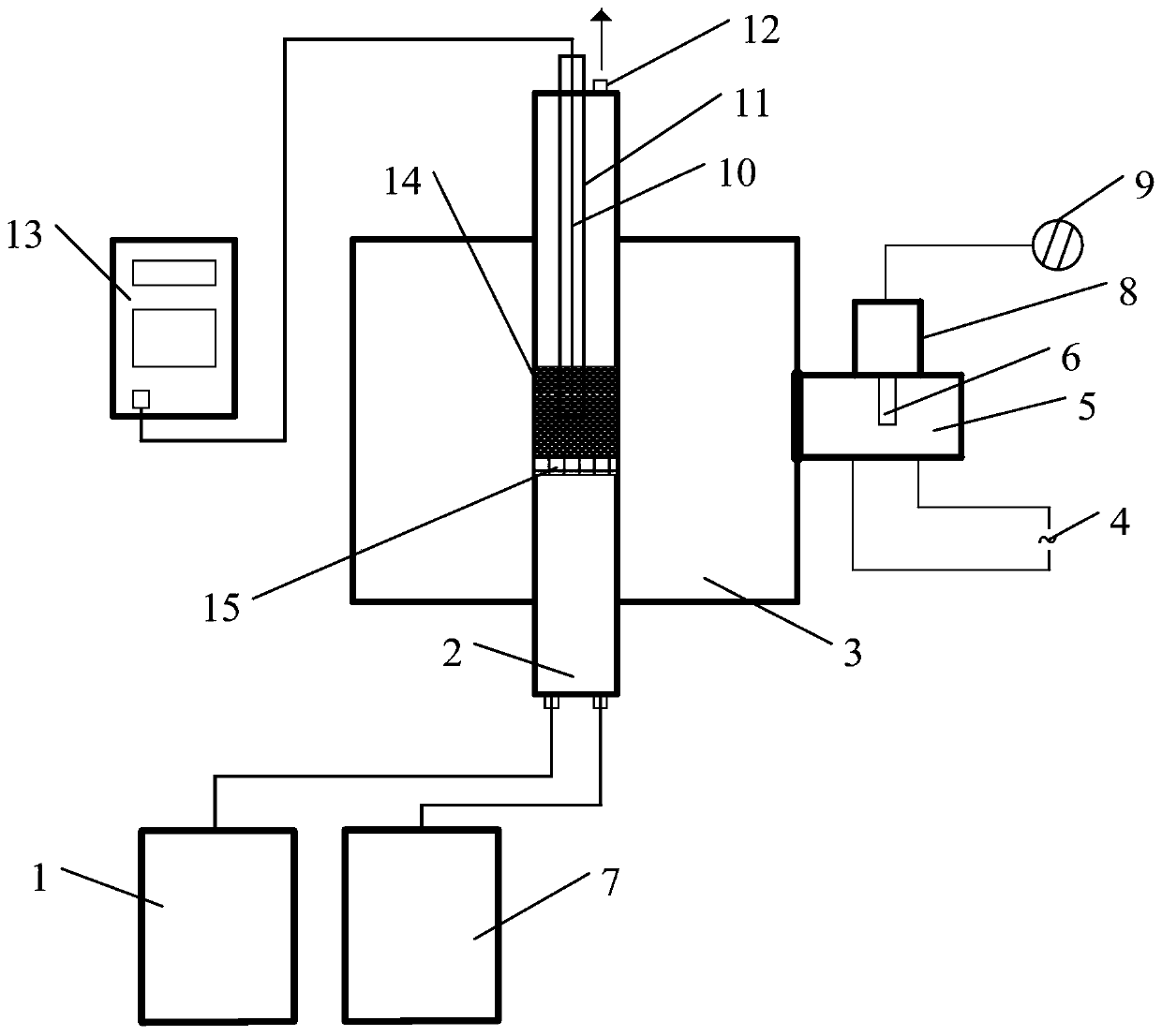

[0043] The structure of the microwave-fluidized roasting device for processing complex refractory iron ore is as follows: figure 1 As shown, it includes a reaction chamber (2) and a microwave cavity (3) that is enclosed within it. The reaction chamber (2) is a cylindrical shape with upper and lower ends closed, and a quartz mesh (15) is provided inside; a thermocouple (10) Insert from the top of the reaction chamber (2), there is a gap between the bottom of the thermocouple (10) and the quartz mesh (15); the bottom of the reaction chamber (2) is provided with a protective gas inlet and a reducing gas inlet , the top is provided with an exhaust port (12); the microwave cavity (3) is equipped with a microwave generating device outside, and the microwave generating device is composed of a waveguide (5), a magnetron (8) and an antenna cap (6), and the waveguide (5 ) is connected to the power supply, the waveguide (5) is located below the magnetron (8), the microwave power meter (9...

Embodiment 2

[0054] Device structure is the same as embodiment 1;

[0055] Method is with embodiment 1, and difference is:

[0056] (1) The raw material of complex refractory iron ore is ore from a certain place in Yunnan, which belongs to hematite-limonite type complex refractory iron ore. The grade of TFe in this ore is 35.25%, containing FeO 9.24% by mass percentage, SiO 2 49.41%, harmful element phosphorus 0.88%;

[0057] (2) The part that is ground to a particle size of ≤0.074mm accounts for 75% of the total mass;

[0058] (3) The protective gas is CO 2 ; The reducing gas is H 2 ; The volume flow rate of the reducing gas accounts for 20% of the total volume flow rate of the reducing gas and the protective gas; the reaction temperature is 560°C, and the microwave-fluidized roasting reaction time is 4 minutes; the heating time is 5 minutes;

[0059] (4); Microwave roasting ore grinding to a particle size of ≤0.038mm accounts for 70% of the total mass, and weak magnetic separation ...

Embodiment 3

[0061] Device structure is the same as embodiment 1;

[0062] Method is with embodiment 1, and difference is:

[0063] (1) The complex refractory iron ore raw material used is hematite-siderite mixed ore in a certain place in Anshan, with a TFe grade of 34.43%, containing 9.24% FeO and SiO by mass percentage 2 49.41%, the harmful elements phosphorus and sulfur are 0.07% and 0.05% respectively;

[0064] (2) The part that is ground to a particle size of ≤0.074mm accounts for 80% of the total mass;

[0065] (3) The protective gas is CO 2 ; The reducing gas is CH 4 ; The volume flow rate of the reducing gas accounts for 30% of the total volume flow rate of the reducing gas and the protective gas; the reaction temperature is 570°C, and the microwave-fluidized roasting reaction time is 8 minutes; the heating time is 4 minutes;

[0066] (4) Microwave roasting ore grinding until particle size ≤ 0.038mm accounts for 80% of the total mass, and weak magnetic separation is carried ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com