A system and method for fast ion conductor coating lithium-ion battery cathode material

A technology of positive electrode materials and ion conductors, which is applied in the fields of chemical industry and lithium ion battery materials, can solve the problems affecting the electrochemical performance of positive electrode materials, and cannot realize the continuous production of high-efficiency, controllable and fast ion conductor coating, and achieve good economic and social benefits , low production energy consumption and operating costs, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

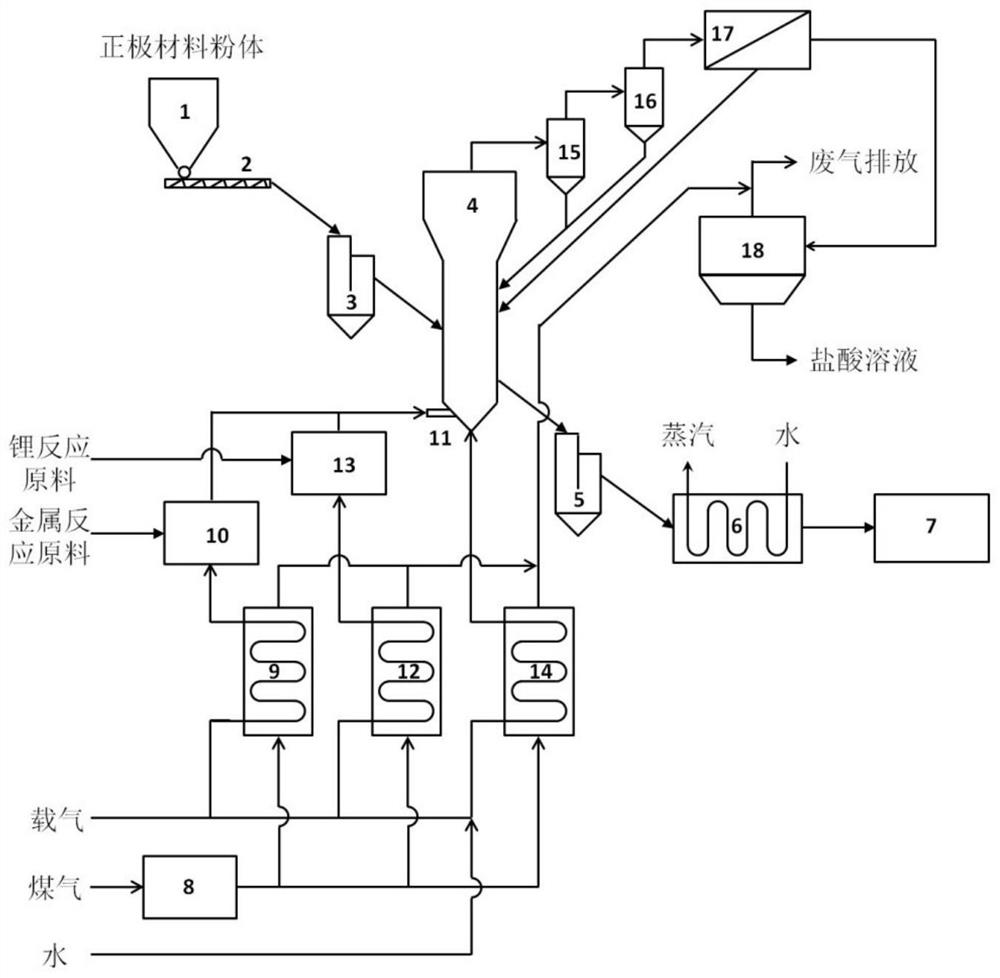

[0030] A system of fast ion conductors coating cathode materials of lithium-ion batteries

[0031] Such as figure 1 As shown, the system includes silo 1, screw feeder 2, feed valve 3, fluidized bed reactor 4, discharge valve 5, product cooler 6, product collector 7, burner 8, No. 1 Reaction carrier gas preheater 9, metal reaction raw material generator 10, reaction raw material nozzle 11, No. 2 reaction carrier gas preheater 12, lithium reaction raw material generator 13, fluidized carrier gas preheater 14, primary cyclone separation Device 15, secondary cyclone separator 16, bag filter 17 and hydrochloric acid tail gas absorber 18;

[0032] The discharge port of the silo 1 is connected with the feed port of the screw feeder 2, and the discharge port of the screw feeder 2 is connected with the feed port of the feed valve 3, and the feed valve The discharge port of 3 is connected with the feed port of fluidized bed reactor 4, and the gas inlet of described fluidized bed react...

Embodiment 2

[0034] A method for fast ion conductor coating lithium ion battery cathode material:

[0035] The method for coating and modifying the fast ion conductor includes the following steps: the positive electrode material powder enters the fluidized bed reactor 4 from the silo 1 through the screw feeder 2 and the feed valve 3 to stay for a certain period of time, and passes through the primary cyclone Separator 15, secondary cyclone separator 16 and bag filter 17 collect and return to fluidized bed reactor 4;

[0036] After the coal gas is heated by the burner 8, heat is exchanged through the No. 1 reaction carrier gas preheater 9, the No. 2 reaction carrier gas preheater 12 and the fluidized carrier gas preheater 14. The gas is preheated, and the gas discharged from the heat exchange is directly Emitted as exhaust gas. The carrier gas and water are sent together into the fluidized carrier gas preheater 14 for preheating, and the preheated mixed gas enters the fluidized bed reactor...

Embodiment 3

[0038] Using the coating process described in Example 2, the ternary nickel cobalt lithium manganese oxide material enters the fluidized bed reactor 4 from the silo 1 through the screw feeder 2 and the feed valve 3, and passes through the No. 1 reaction carrier gas The nitrogen temperature after the preheater 9 is 155°C, and enters the metal reaction raw material generator 10 to heat the reaction raw material tantalum ethoxide, and the nitrogen temperature after passing through the No. 2 reaction carrier gas preheater 12 is 40°C, and enters the lithium reaction raw material generator 13 Heating lithium tert-butoxide, the mixed gas enters the fluidized bed reactor 4 through the reaction raw material nozzle 11, wherein the mass ratio of tantalum ethoxide to lithium tert-butoxide is 1:5, and at the same time, another path of nitrogen passes through the fluidized carrier gas to preheat After the heater 14 is preheated, it forms a mixed gas with water vapor and enters the fluidized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com