Abnormity warning and processing system of continuously-producing process

An abnormal alarm and processing system technology, applied in general control system, control/regulation system, comprehensive factory control, etc., can solve the problems of continuous and stable production of unfavorable polyurethane products, untimely processing, illegal processing, etc., and achieve continuous and stable operation , improve processing speed, and avoid accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

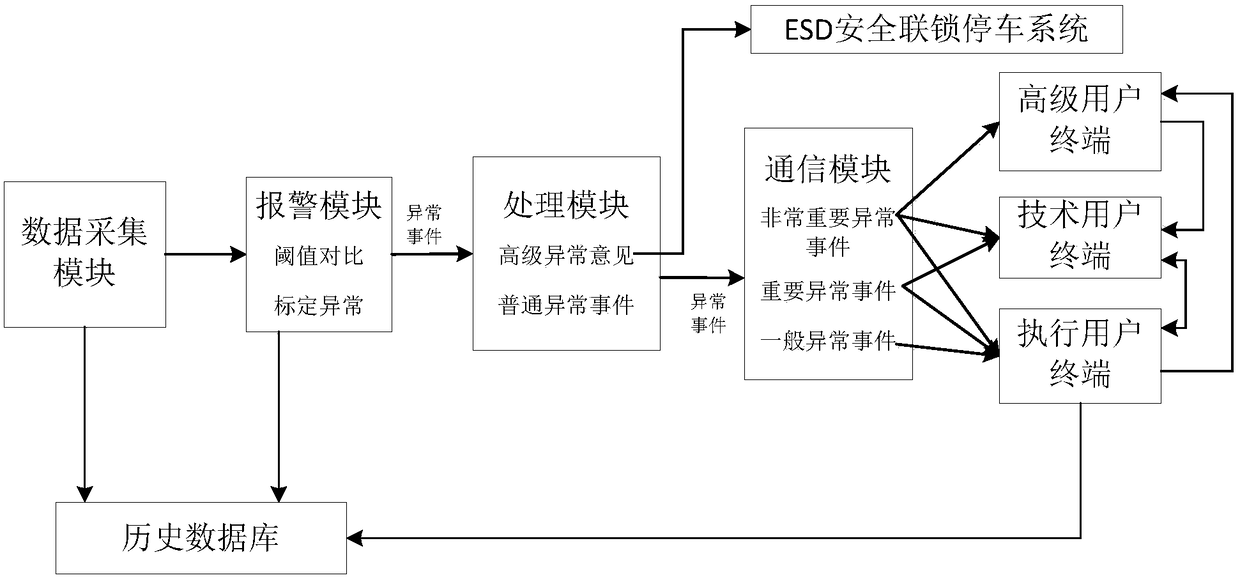

[0024] The invention provides a process abnormality alarm and processing system for continuous production, including: a data acquisition module, an alarm module, a historical database, a processing module, a communication module, and a user terminal; wherein, the user terminal is divided into an execution user terminal, a technical user terminal terminals and power user terminals. Among them, the user who executes the user terminal is generally the operator of the production line, the user of the technical user terminal is generally a technician, and the user of the advanced user terminal is generally the company leader.

[0025] The data acquisition module is used to collect the data of various process parameters in real time, and send the collected data to the alarm module, and store the collected data in the historical database at the same time;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com