Intelligent rail guide vehicle (RGV) control device based on two vehicles on one rail

A technology of intelligent control and trolley, which is applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems such as the inability to realize automatic control, achieve a high degree of automation, and ensure the effect of continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the specific embodiments shown in the drawings. However, these embodiments do not limit the present invention, and the structural, method, or functional changes made by those skilled in the art based on these embodiments are all included in the protection scope of the present invention.

[0016] RGV (Rail Guide Vehicle) is a rail pallet handling vehicle that can be used in conjunction with a pallet conveyor. It can be used for circular or linear transmission, and it can be powered by sliding contact line or tow cable.

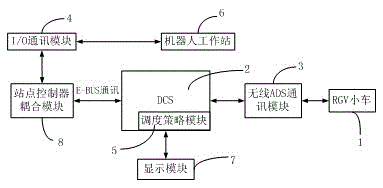

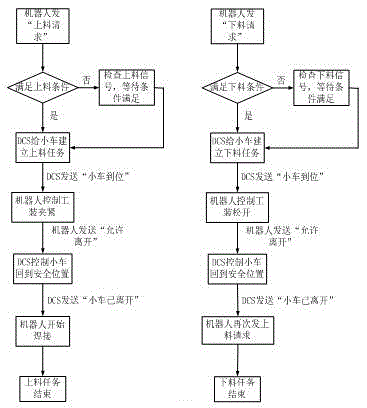

[0017] Such as figure 1 As shown, an intelligent control device for RGV trolleys based on two cars on the same track of the present invention includes two RGV trolleys on the same track 1, a DCS control system (Distributed Control System, distributed control system) 2, a wireless ADS (Automation Device Specification) , Automation equipment specifications) communication module 3, I / 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com