Method for patching damaged blast furnace hot air pipeline inner liner in hot state

A technology of hot repair and hot air pipes, applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems affecting blast furnace production, shedding, large losses, etc., and achieve the effect of ensuring normal continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given hereby, and the details are as follows:

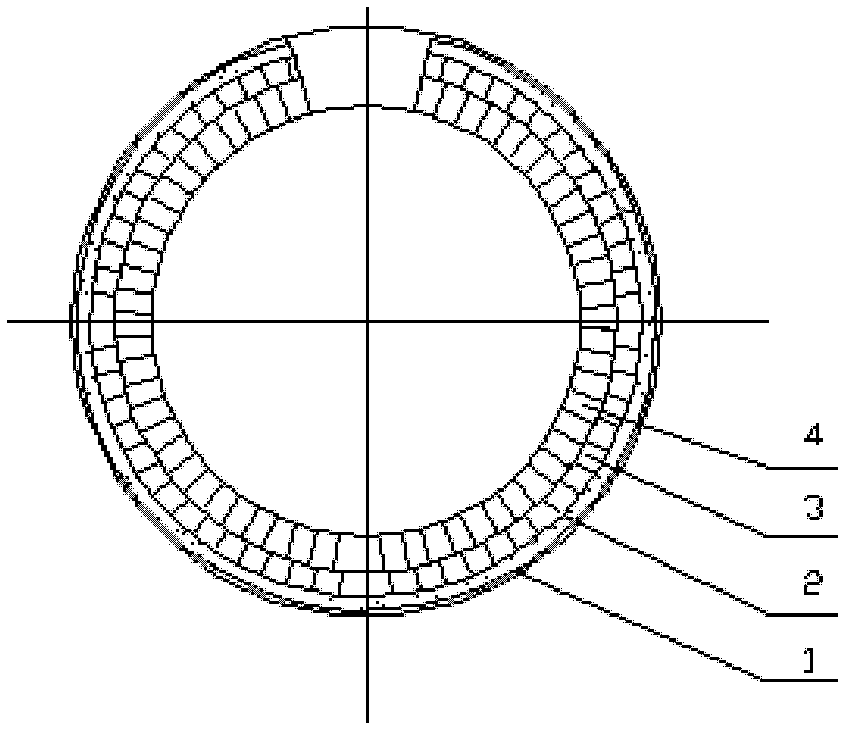

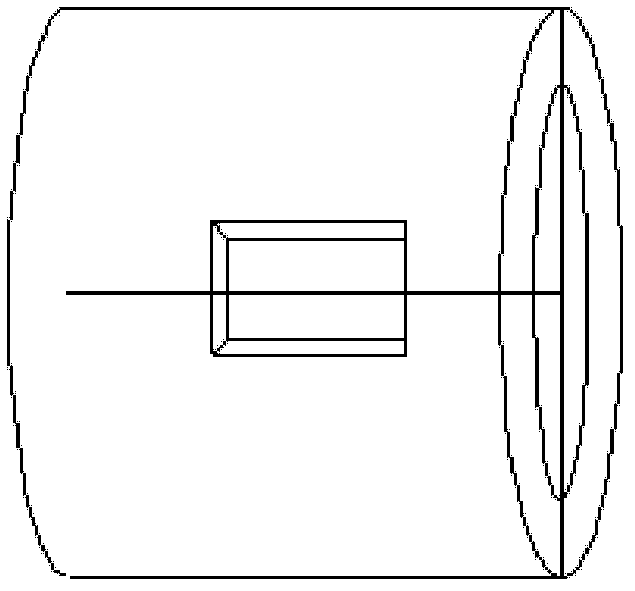

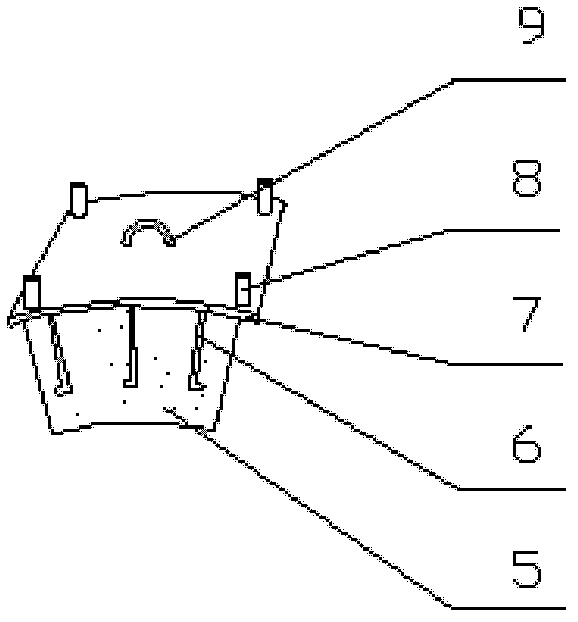

[0020] see Figure 1 ~ Figure 4 , according to the damaged condition of the pipeline lining, a method for thermally repairing the damaged blast furnace hot blast pipeline lining comprises the following steps:

[0021] A. According to the heating position of the pipeline, judge the damage of the inner lining, select the welding plate 7 with the same thickness as the steel shell 1 of the pipeline in advance, and curl it according to the diameter of the steel shell 1 of the pipeline, and the size should be larger than the area of the damaged inner lining;

[0022] B. Make several fixed hooks 6 whose length is less than the thickness value of the pipeline lining, and distribute and weld them on the curled welding plate 7. A lifting lug 9 is arranged in the middle of the upper end surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com