Method and device for improving quality of narrow lap welder weld joint

A lap welding and quality technology, applied in the field of metallurgical welding, can solve the problems of inability to detect weld defects online, inability to directly detect and evaluate weld quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0167] System parameters

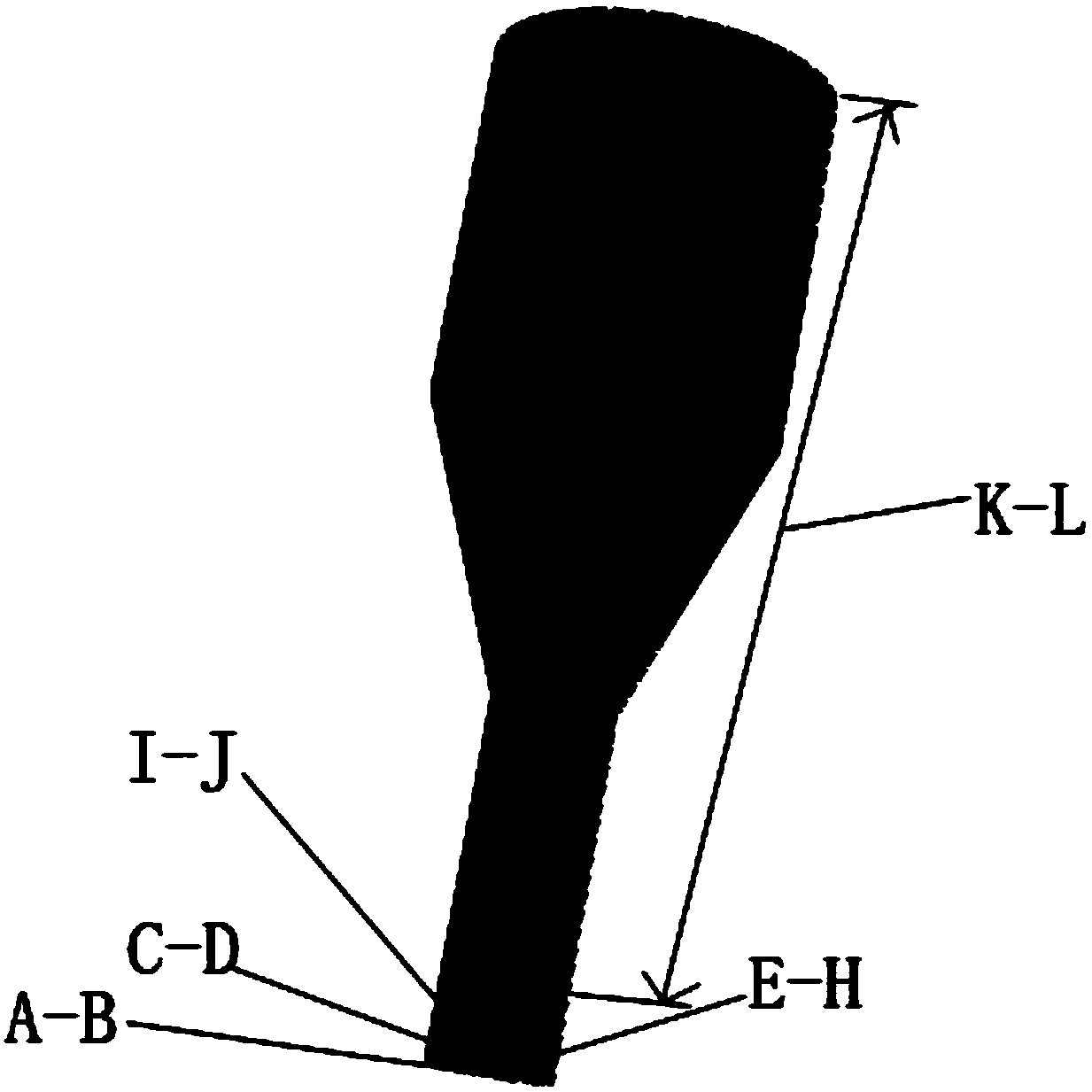

[0168] For narrow lap resistance welding, the welding situation of the substrate thickness is 0.14-0.19mm.

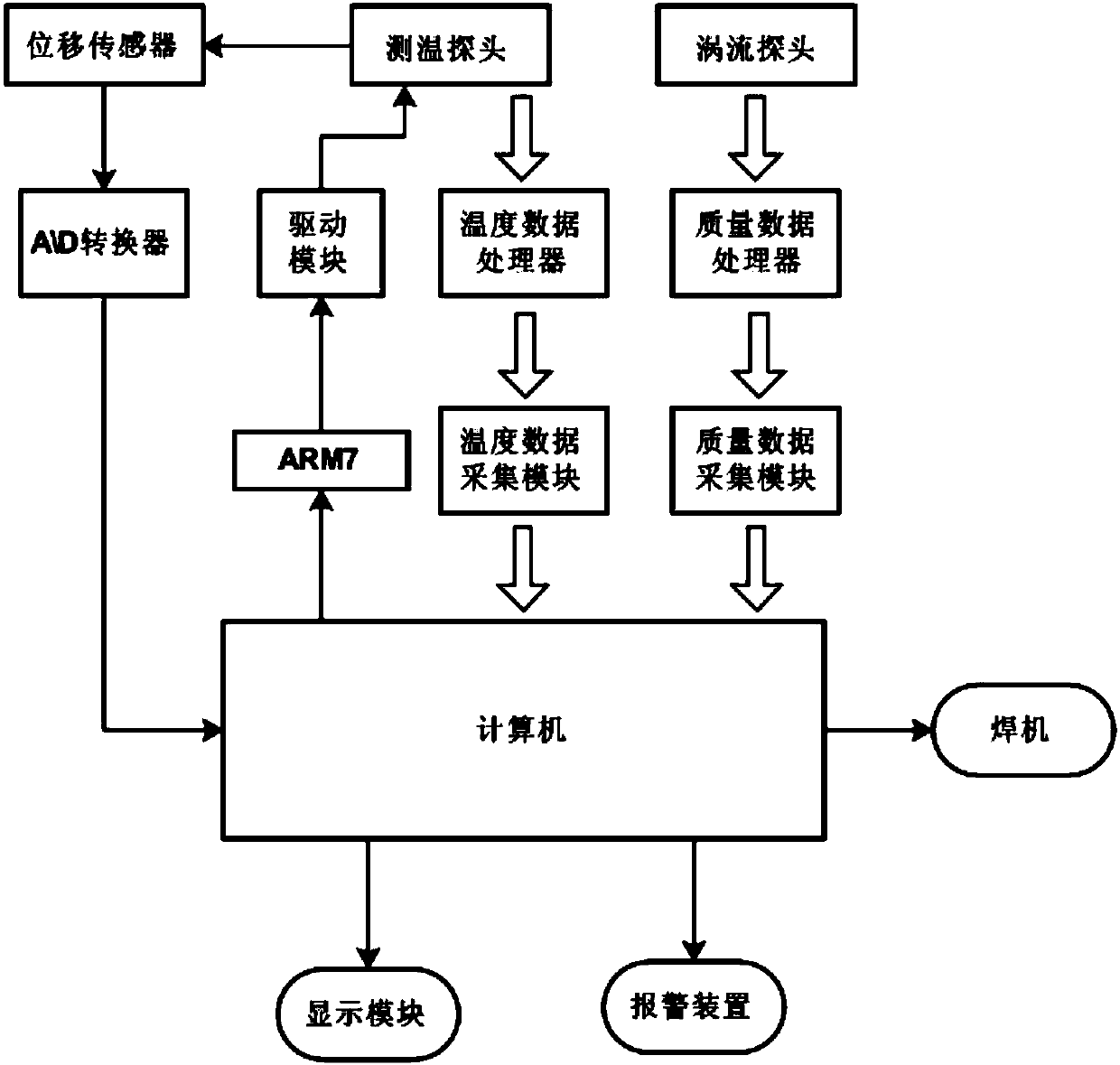

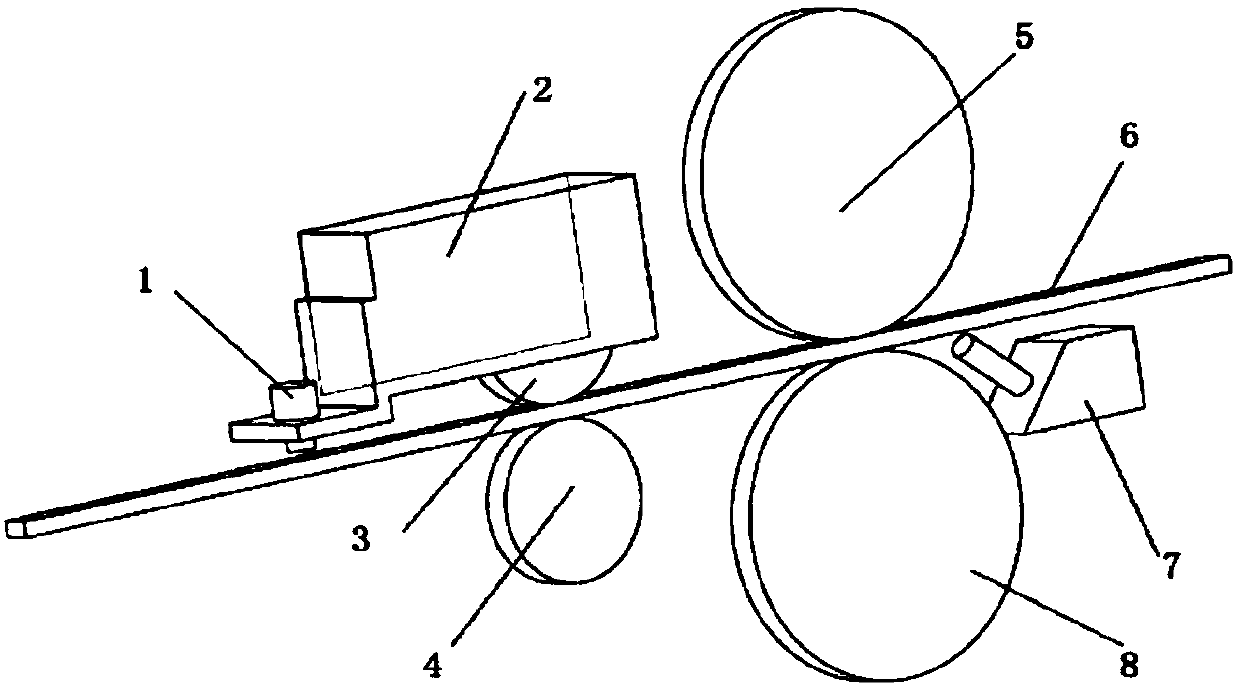

[0169] The temperature measuring probe 15 is anti-electromagnetic interference and dust-proof. When installing, the vertical distance between the temperature measuring point and the welding seam 6 is 3mm, and the linear distance from the center of the lower welding wheel 8 is 105mm, so as to ensure that the center of the temperature measuring point and the center of the welding wheel Alignment, synchronous movement with welding machine.

[0170] The pulsed eddy current probe 1 is used to detect the quality of the weld after welding, which is installed behind the roller 3 on the narrow lap resistance welding machine, at a distance of more than 1m from the upper welding wheel, and moves synchronously with the welding machine to ensure real-time detection . The advantage of using pulsed eddy current testing is that the detection sensitivity is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com