Tea seed continuous cold pressing process

A technology of cold pressing and tea seeds, applied in the project field, can solve the problems of stuck oil press, high cost of tempering pot, not working properly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

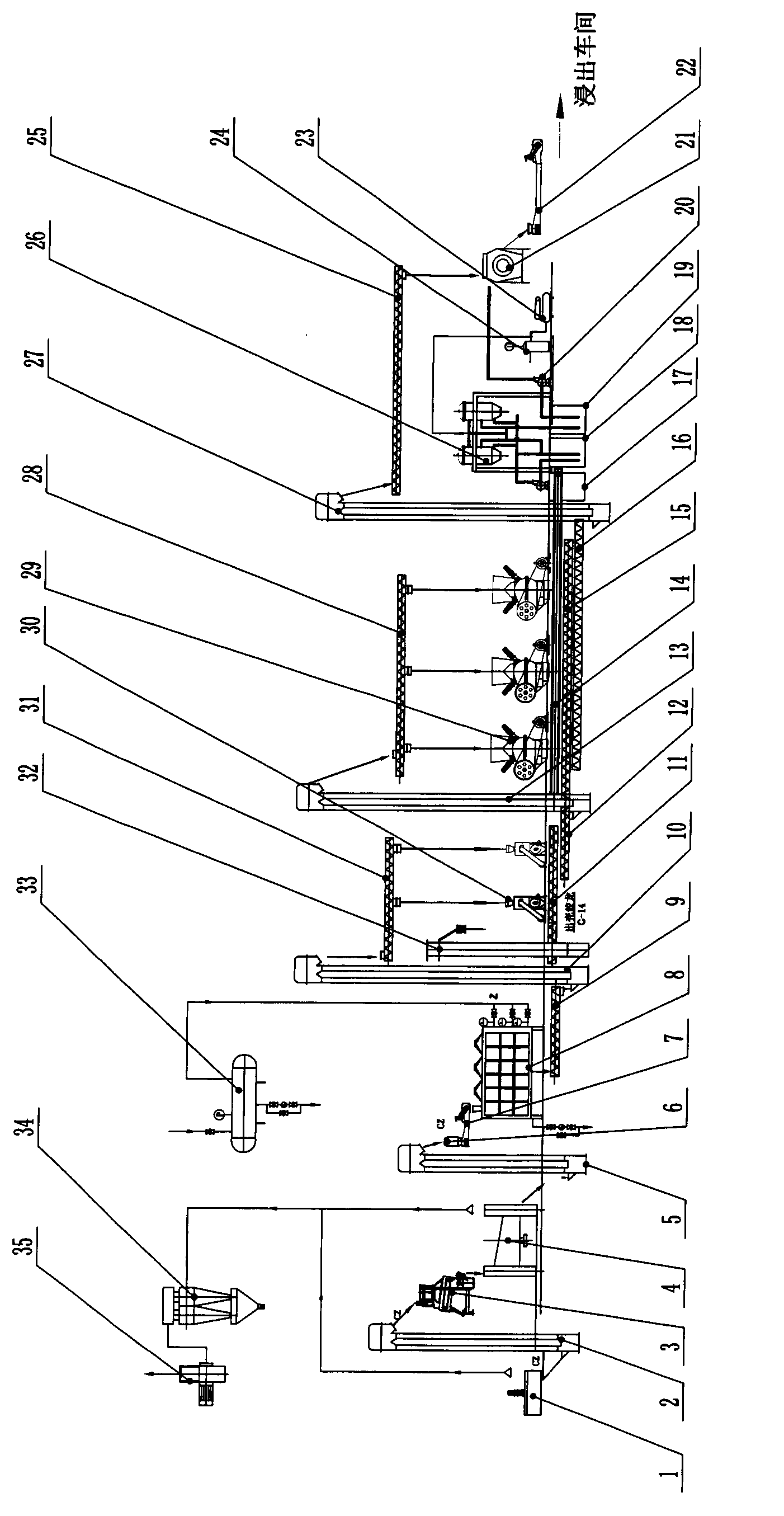

[0006] The specific process of the process of the present invention: Camellia oleifera seeds enter the feeder 1 and are transported to the No. 1 hoist 2 with a constant flow rate; the No. 1 hoist 2 is transported to the de-stoner 3, and the de-stoned camellia seeds are transported to the vibrating screen 4 for further processing. Other impurities are separated; the dust generated during separation is discharged outdoors through the action of the dust collector 34 and the blower fan 35. The cleaned Camellia oleifera seeds are conveyed by the No. 2 hoist 5, and the iron-containing substances in the oil seeds are absorbed by the magnetic separator 6, and the oil seeds enter the flat-plate dryer 8 through the feeding flat scraper 7, and the flat-plate dryer 8 is equipped with heating system; the steam delivered from the steam distributor 33 is distributed to the flat dryer 8 through the steam distributor 33; the oilseed enters from the top of the flat dryer 8 and runs from top to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com