Gas pipe corrosion defect under-pressure repair method

A technology of gas pipeline and repair method, which is applied in the direction of pipe components, pipes/pipe joints/pipe fittings, mechanical equipment, etc., which can solve the problems of high safety risk, short life, easy perforation, etc., and achieve the goal of avoiding potential safety hazards and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

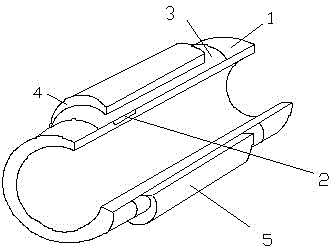

[0020] like figure 1 As shown, the pressure repair method of gas pipeline corrosion defect of the present invention comprises the following steps:

[0021] Step 1. Clean the surface of the repaired part of the pipeline 1. Use a copper brush or a rust remover to remove scale, loose rust, old coatings and dirt; during the cleaning period, the firm and smooth paint on the surface of the pipeline 1 does not need to be removed;

[0022] Step 2: Use the repairing agent 2 to fill the perforated leaking part or the corroded part of the outer surface of the pipeline 1. The rigidity hardness, compressive strength, tensile strength and shear strength of the curing agent 2 after curing are similar to those of the carbon steel material used in the pipeline 1;

[0023] Step 3: Apply epoxy resin primer 3 to the part of the surface of the pipeline 1 that needs to be coated, and the thickness of the epoxy resin primer 3 is ≥0.2mm;

[0024] Step 4. The surface of the pipe coated with epoxy res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com