Ablation-resistant anti-aging cover for conveying belt and preparation method thereof

An aging-resistant and conveyor belt technology, applied in the field of rubber conveyor belt products, can solve the problems of aging and cracking of conveyor belts, ironing of skeleton materials, and shortened service life, and achieve good economic benefits, cost savings, and improved service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

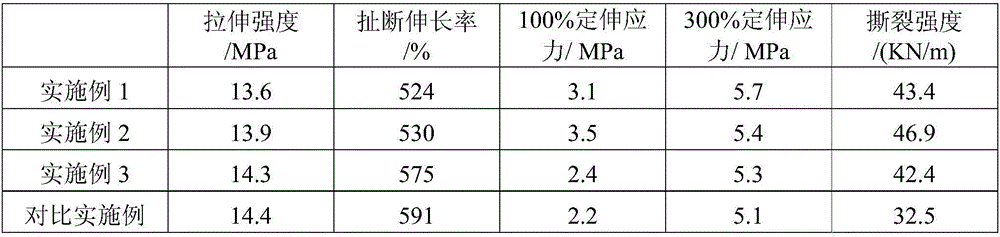

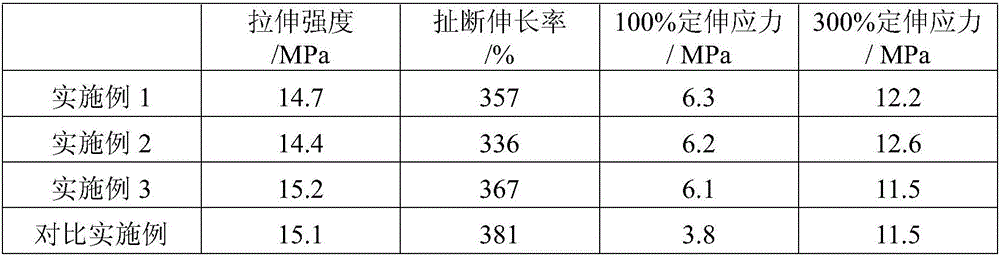

Embodiment 1

[0022] A kind of ablation-resistant aging-resistant conveyor belt cover rubber, each component counts by weight fraction: EPDM rubber (4045) 100 parts, carbon black N330 40 parts, dicumyl peroxide (DCP) 3 parts, 0.5 parts of triallyl isocyanurate (TAIC), 5 parts of zinc oxide, 5 parts of magnesium oxide, 10 parts of paraffin oil, 1 part of anti-aging agent RD, 1 part of anti-aging agent MB, 5 parts of aramid chopped fiber , 5 parts of ammonium polyphosphate (APP), 10 parts of pentaerythritol, 3 parts of polybutadiene grafted with maleic anhydride.

[0023] A preparation method for an ablation-resistant and aging-resistant conveyor belt covering glue comprises the following steps:

[0024] (1) One-stage mixing: put EPDM rubber into the internal mixer, and internally knead for 2 minutes; then open the top bolt, add carbon black, zinc oxide, magnesium oxide, paraffin oil, anti-aging agent RD, anti-aging agent MB, Aramid chopped fiber, ammonium polyphosphate (APP), pentaerythrito...

Embodiment 2

[0028] An ablation-resistant and aging-resistant conveyor belt covering rubber, the components are calculated by weight fraction: 100 parts of EPDM rubber (4045), 10 parts of precipitated white carbon black, 50 parts of carbon black N550, diisoperoxide Propylene (DCP) 5 parts, triallyl isocyanurate (TAIC) 0.5 parts, zinc oxide 10 parts, magnesium oxide 5 parts, paraffin oil 15 parts, antioxidant RD 1.5 parts, antioxidant MB 1.5 parts , masterbatch pre-dispersed aramid pulp 5 parts, zinc borate 20 parts, phenolic resin 15 parts, maleic anhydride grafted polybutadiene 3 parts.

[0029] A preparation method for an ablation-resistant and aging-resistant conveyor belt covering glue comprises the following steps:

[0030] (1) One-stage mixing: put EPDM rubber into the internal mixer, and internally mix for 2 minutes; then open the top bolt, add white carbon black, carbon black, zinc oxide, magnesium oxide, paraffin oil, anti-aging agent RD, Anti-aging agent MB, masterbatch pre-disp...

Embodiment 3

[0034] An ablation-resistant and aging-resistant conveyor belt covering rubber, the components are calculated by weight fraction: 100 parts of EPDM rubber (4045), 20 parts of precipitated white carbon black, 50 parts of carbon black N550, diisoperoxide Propylene (DCP) 5 parts, triallyl isocyanurate (TAIC) 1.5 parts, zinc oxide 20 parts, magnesium oxide 5 parts, paraffin oil 20 parts, antioxidant RD 2 parts, antioxidant MB 2 parts , 8 parts of short glass fiber, 20 parts of decabromodiphenylethane, 20 parts of phenolic resin, 2 parts of γ-aminopropyltriethoxysilane (KH-550).

[0035] A preparation method for an ablation-resistant and aging-resistant conveyor belt covering glue comprises the following steps:

[0036](1) One-stage mixing: put EPDM rubber into the internal mixer, and internally mix for 2 minutes; then open the top bolt, add white carbon black, carbon black, zinc oxide, magnesium oxide, paraffin oil, anti-aging agent RD, Anti-aging agent MB, glass short fiber, dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com