High-dispersion type catalyst for liquid phase hydrogenation of octanol mixture, and preparation and application thereof

A liquid-phase hydrogenation and mixture technology, which is applied in the preparation of hydroxyl compounds, organic compounds, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of hydrogenation effect to be improved, and achieve good industrial application Prospect, optimization of reductive activation process, effect of reduced coalescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

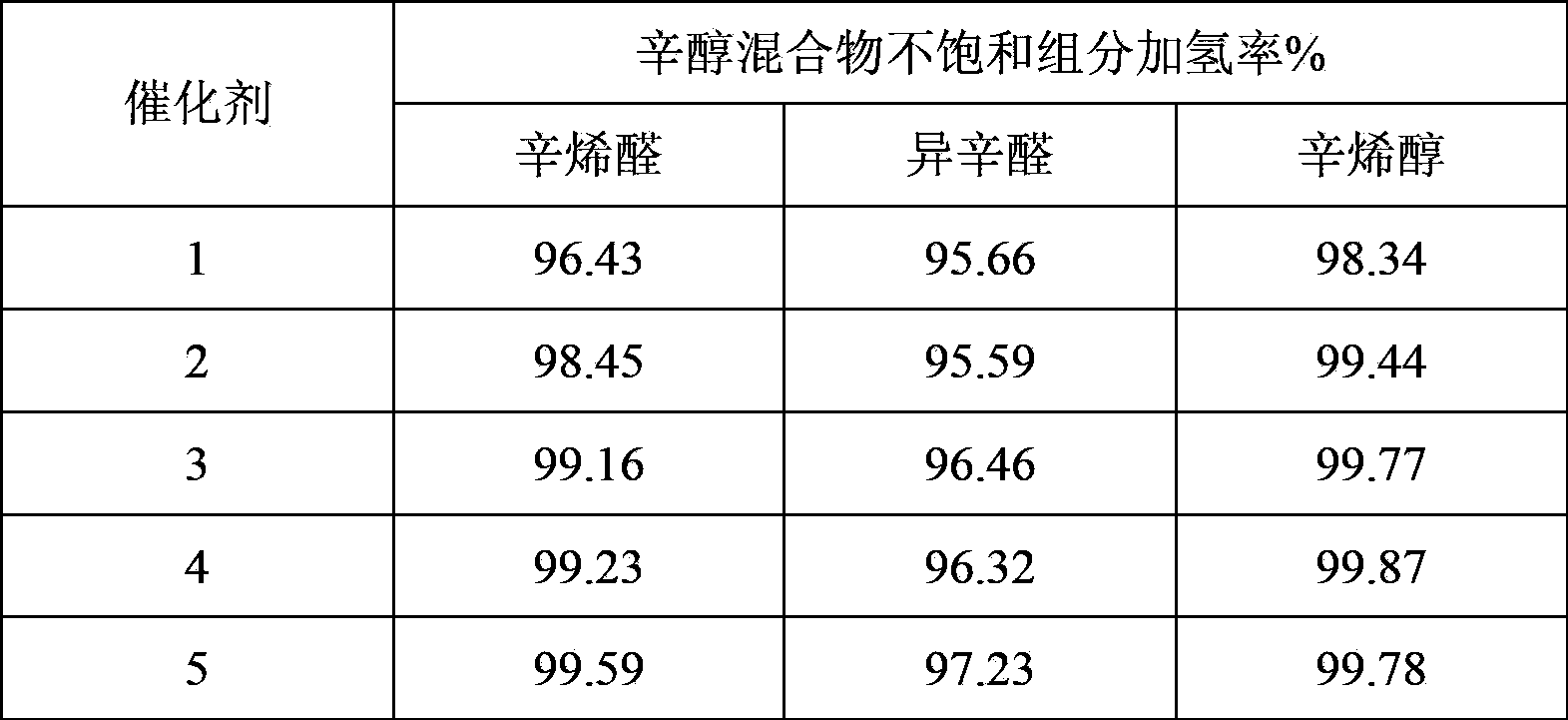

Examples

Embodiment 1

[0031] Add 500g of pseudo-boehmite powder, 8g of scallop powder, 12g of concentrated nitric acid, and 450ml of water, fully knead, and extrude into The clover-shaped strip-shaped carrier is dried at 120°C for 20 hours, and then roasted at 600°C for 5 hours to obtain the required carrier A; 0.02mol / L lanthanum nitrate solution B is prepared, and 20g of carrier A Immerse in lanthanum nitrate solution B, the immersion temperature is 50°C, and the immersion time is 6h. After the impregnation is completed, dry at 110°C and roast at 450°C for 3 hours to obtain a rare earth La modified carrier; configure 0.5mol / L nickel nitrate + 0.3mol / L copper nitrate + 0.05mol / L manganese nitrate + 1mol / L Urea mixed solution C; add the rare earth La modified carrier into solution C, put it in an autoclave, and place it at 110° C. for 24 hours. After the reaction is completed, the catalyst precursor can be prepared by drying at 120° C. for 10 hours and roasting at 500° C. for 5 hours. at 400°C a...

Embodiment 2

[0033] Add 500g of pseudo-boehmite powder, 7g of scallop powder, 14g of concentrated nitric acid, and 400ml of water, fully knead, and extrude into The four-leaf clover-shaped strip carrier was dried at 130°C for 10 hours, and then roasted at 600°C for 5 hours to obtain the required carrier A; 0.04mol / L lanthanum nitrate solution B was prepared, and 20g of The carrier A is impregnated in the lanthanum nitrate solution B, the immersion temperature is 60°C, and the immersion time is 12h. After the impregnation is completed, dry at 110°C for 8 hours, and roast at 500°C for 4 hours to prepare the rare earth La modified carrier; configure 1mol / L nickel nitrate + 0.5mol / L copper nitrate + 0.03mol / L manganese nitrate + 1mol / L Formamide mixed solution C; add the rare earth La-modified carrier into solution C, put it in an autoclave, and place it at 105°C for 24 hours. After the reaction is completed, the catalyst precursor can be prepared by drying at 110° C. for 16 hours and roasti...

Embodiment 3

[0036] Add 500g of pseudo-boehmite powder, 7g of scallop powder, 10g of concentrated nitric acid, and 450ml of water, fully knead, and extrude into The clover-shaped strip carrier of the clover-shaped carrier was dried at 110°C for 20 hours, and then roasted at 550°C for 8 hours to obtain the required carrier A; 0.02mol / L lanthanum nitrate solution B was prepared, and 20g of carrier A is immersed in the lanthanum nitrate solution B, the immersion temperature is 50°C, and the immersion time is 12h. After the impregnation is completed, dry at 110°C for 12 hours, and roast at 500°C for 6 hours to obtain a rare earth La modified carrier; configure 1.5mol / L nickel nitrate + 0.2mol / L copper nitrate + 0.1mol / L manganese nitrate + 1.5mol / L urea mixed solution C; the rare earth La modified carrier was added to solution C, placed in an autoclave, and placed at 110°C for 30 hours. After the reaction is completed, the catalyst precursor can be prepared by drying at 120° C. for 8 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com