Multideposition SACVD reactor

a chemical vapor deposition and reactor technology, applied in chemical vapor deposition coating, coating, metallic material coating process, etc., can solve the problems of inability to deposit sisub>3/sub>n, time-consuming operation, and device density and complexity increase, and achieve the effect of rapid thermal deposition of dielectric materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

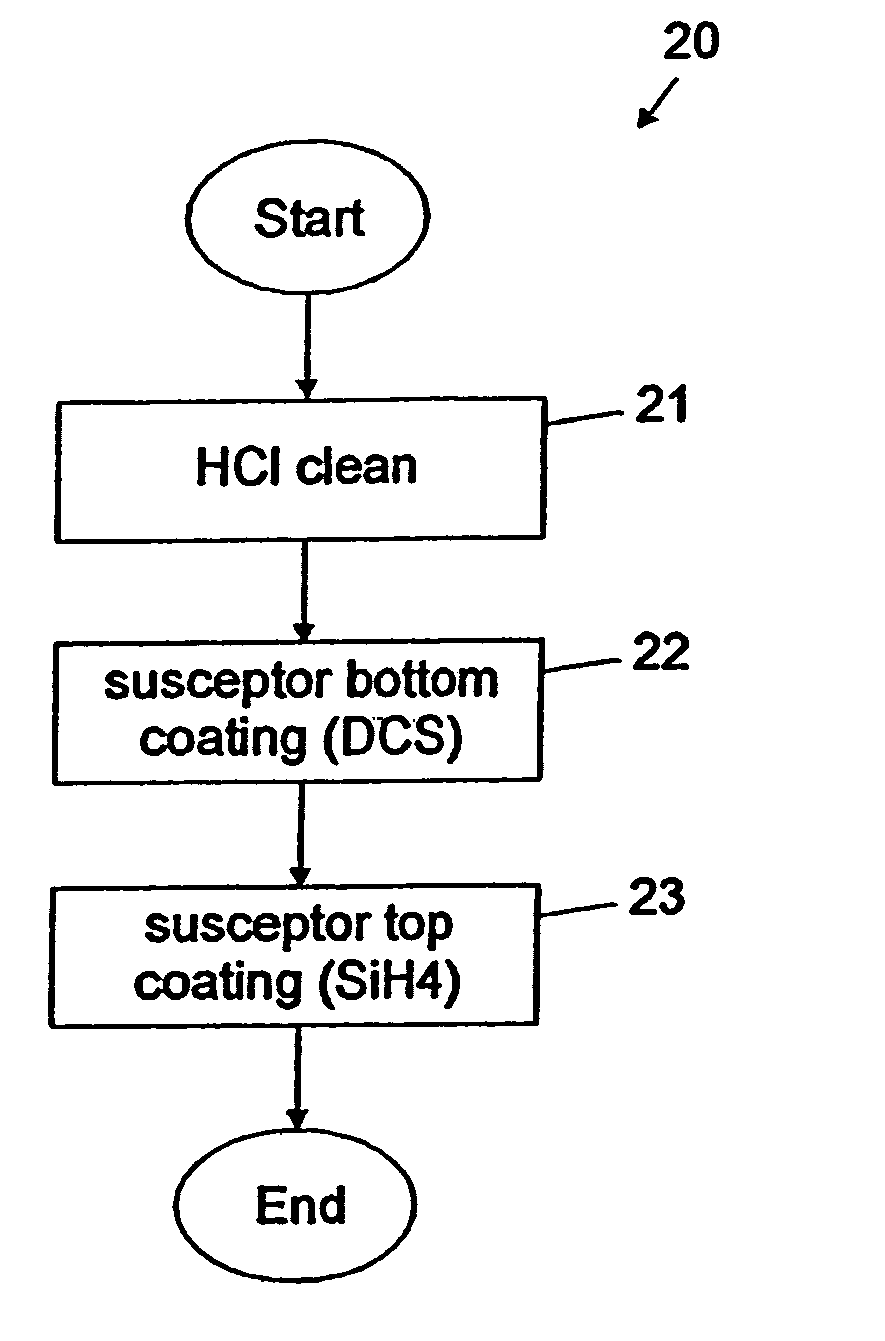

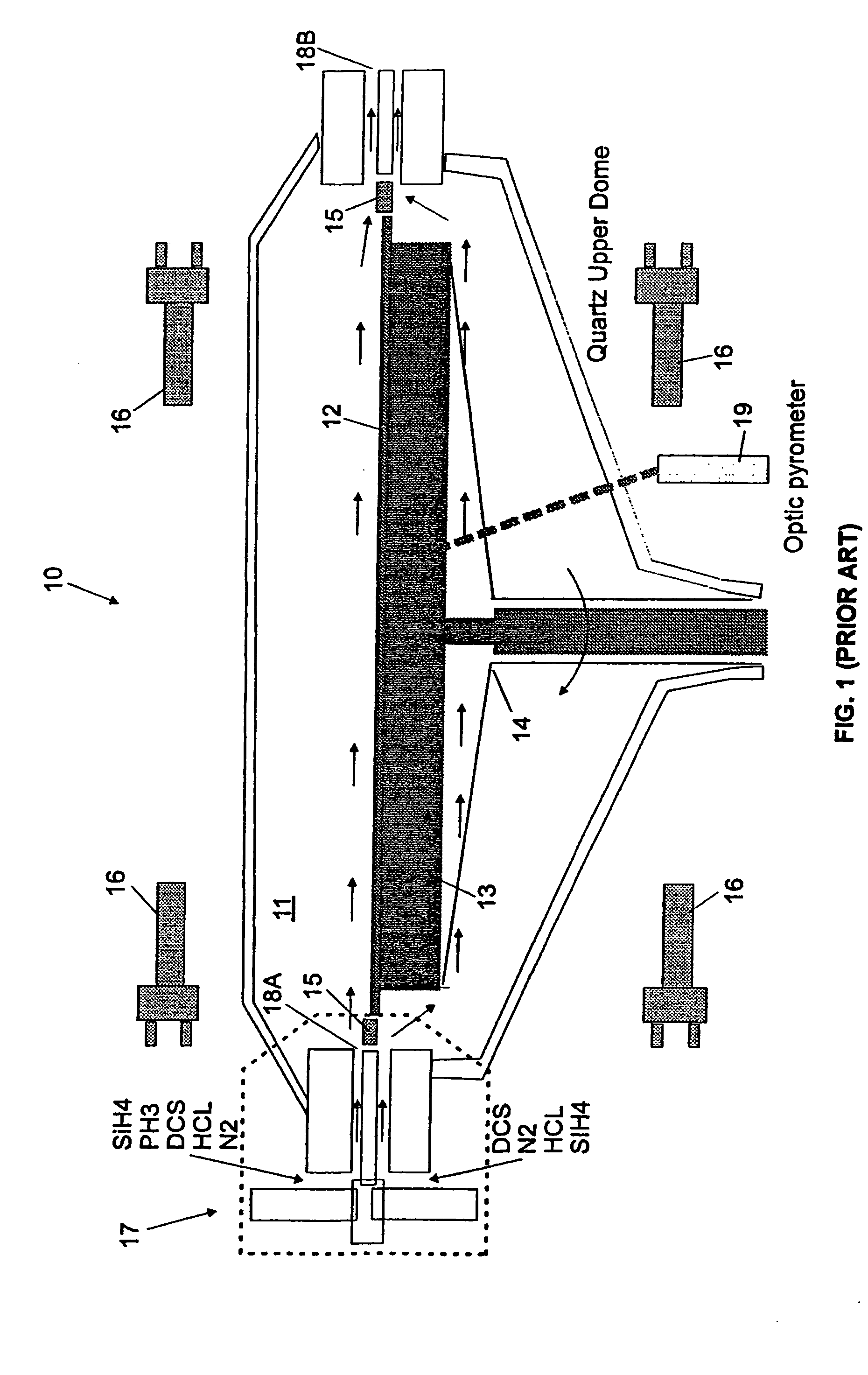

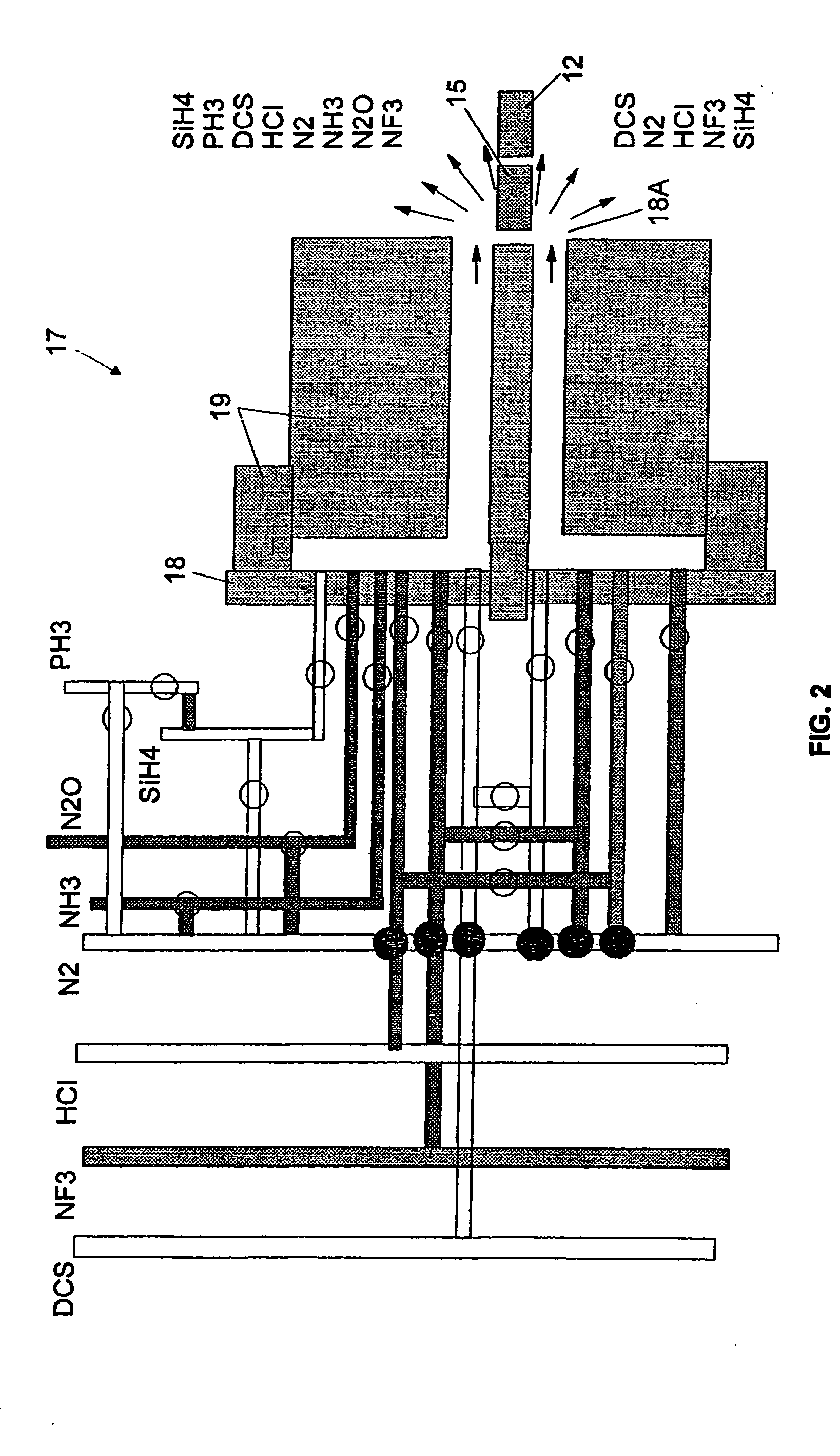

[0055] Historically, LPCVD processes have been performed in vertical furnaces. In the past several years, new deposition tools have become available which overcome the limitations of vertical furnaces because they are single-wafer processing based systems. The SACVD Centura HTF reactor is a good example of that new generation of deposition equipments. However, it is strictly limited to the deposition of polysilicon films. It is a cold-wall reactor that uses radiant heating for thermal energy. It operates at reduced pressure and in a temperature range of 550-1200° C. (depending upon the type of operation: deposition or cleaning). FIG. 1 schematically shows the cross-section of the SACVD Centura reactor with its major elements. Now tuning to FIG. 1, reactor 10 has top and bottom walls (dome), side walls and a bottom wall that define the internal volume of the processing vacuum chamber 11 into which a substrate, typically a silicon wafer 12, can be loaded. The wafer 12 sits on a carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com