Three-dimensional porous titanium substrate lead dioxide electrode as well as preparation method and application thereof

A lead dioxide, three-dimensional porous technology, used in chemical instruments and methods, water/sewage treatment equipment, water pollutants, etc., can solve the problems of long method time and low degradation efficiency, and achieve short degradation time and high degradation rate. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

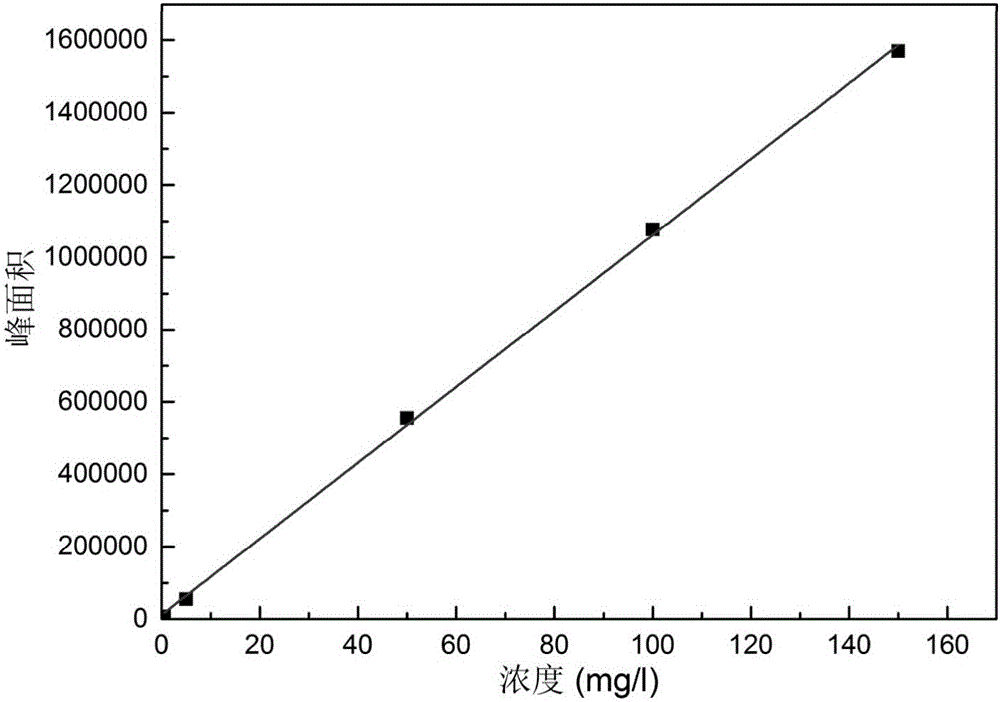

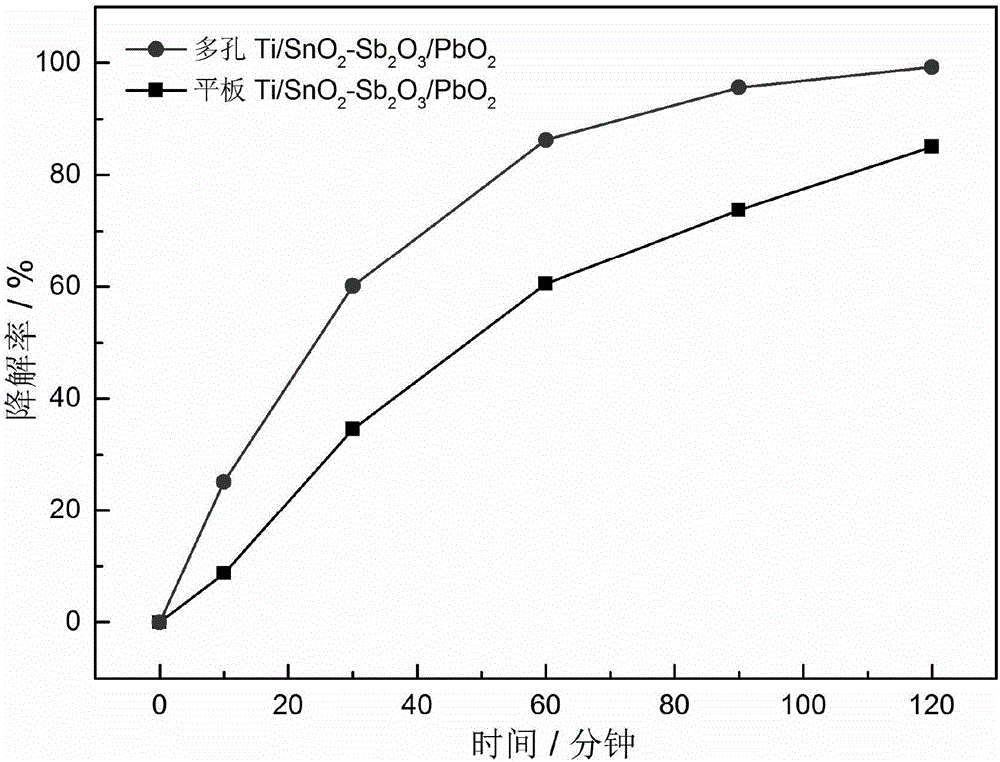

[0028] A method for degrading waste water containing ketone musk by using a lead dioxide electrode of a flat titanium matrix, the specific implementation method is as follows:

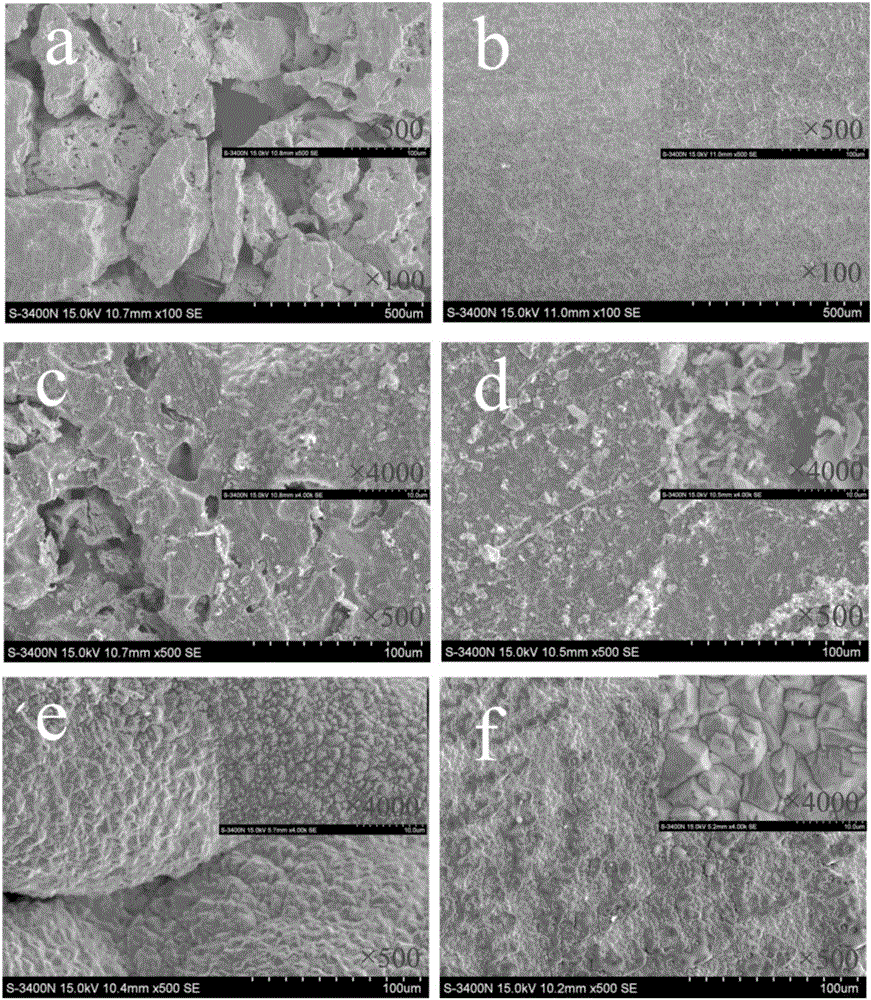

[0029] (1) First, use mechanical polishing to remove oxides and impurities on the surface of the electrode substrate, then sand the corners with sandpaper to make them smooth, and finally rinse them with deionized water; secondly, immerse the entire electrode in sodium hydroxide lotion to keep Each pole piece is in a separated state, heated to 55°C~85°C, kept at a constant temperature for 35 minutes to 55 minutes, stopped heating, cooled, rinsed with deionized water; then immersed the entire electrode in hydrochloric acid washing solution, at 95°C Treat at 100°C for 35 minutes to 55 minutes, rinse surface impurities with deionized water, and finally ultrasonically clean in ultrapure water for 25 minutes to 45 minutes, then store in deionized water or isopropanol. After pretreatment, the flat titanium su...

Embodiment 2

[0047] A method for degrading waste water containing ketone musk by using a three-dimensional porous titanium matrix lead dioxide electrode, the specific implementation method is as follows:

[0048] (1) First, use mechanical polishing to remove oxides and impurities on the surface of the electrode substrate, then sand the corners with sandpaper to make them smooth, and finally rinse them with deionized water; secondly, immerse the entire electrode in sodium hydroxide lotion to keep Each pole piece is in a separated state, heated to 55°C~85°C, kept at a constant temperature for 35 minutes to 55 minutes, stopped heating, cooled, rinsed with deionized water; then immersed the entire electrode in hydrochloric acid washing solution, at 95°C Treat at 100°C for 25 minutes to 45 minutes, rinse the surface impurities with deionized water, and finally ultrasonically clean in ultrapure water for 25 minutes to 45 minutes, then store in deionized water or isopropanol, the pretreated porous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com