Graphene modified fluorine-contained lead dioxide electrode and preparation method thereof

A lead dioxide and graphene technology, applied in chemical instruments and methods, electrolytic coatings, liquid chemical plating, etc., can solve problems such as low current efficiency, service life needs to be further improved, etc., to achieve improved transfer speed, convenient management, The effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

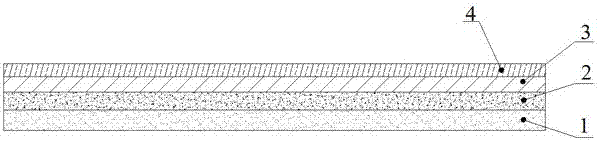

[0040] as attached figure 1 Shown: the structure of graphene modified fluorine-containing lead dioxide electrode of the present invention comprises:

[0041] Titanium substrate 1;

[0042] Graphene-containing tin antimony oxide bottom layer 2 thermally deposited on a titanium substrate;

[0043] Graphene-containing α-PbO deposited on bottom layer 2 by sonoelectrodeposition 2 middle layer 3;

[0044] Graphene-containing β-PbO deposited on the interlayer 3 by sonoelectrodeposition 2 active layer 4.

[0045] The preparation method is as follows:

[0046] (1) Clean the graphite paper with absolute ethanol and deionized water, and dry it in an oven at 60°C for 1 hour. The electrolysis was carried out at a constant voltage using a DC regulated constant current switching power supply, graphite paper was used as the negative and positive electrodes, 100 ml of ammonium persulfate solution with a mass concentration of 0.4% was used as the electrolyte, the distance between the two ...

Embodiment 2

[0054] The preparation method of the electrode is the same as in Example 1.

[0055] The difference is that the sonoelectrodeposition of graphene-containing α-PbO 2 Interlayer and graphene-containing β-PbO 2 The concentration of graphene in the plating solution of the active layer is 0.5 g / L, and a graphene-modified fluorine-containing lead dioxide electrode is obtained.

[0056] The prepared graphene-modified fluorine-containing lead dioxide electrode is used as the anode, and the stainless steel plate of equal area is used as the cathode, and the distance between the electrodes is 1 cm. The electrocatalytic oxidation of phenol in water, the concentration of phenol is 50 mg / L, and the concentration of 0.05 mol / L is Sodium sulfate is used as the supporting electrolyte, the volume of the solution is 200 ml, the distance between the electrodes is 1 cm, and the electrocatalytic oxidation current density is 30 mA / cm 2 , the temperature was 30°C, and the removal rate of phenol wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com