Laminated packaging film for solar batteries

A solar cell and encapsulation film technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high thermal conductivity and water vapor transmission rate, unfavorable power generation efficiency, and no reflection function, so as to achieve high barrier properties and improve Effects of photoelectric conversion efficiency and high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

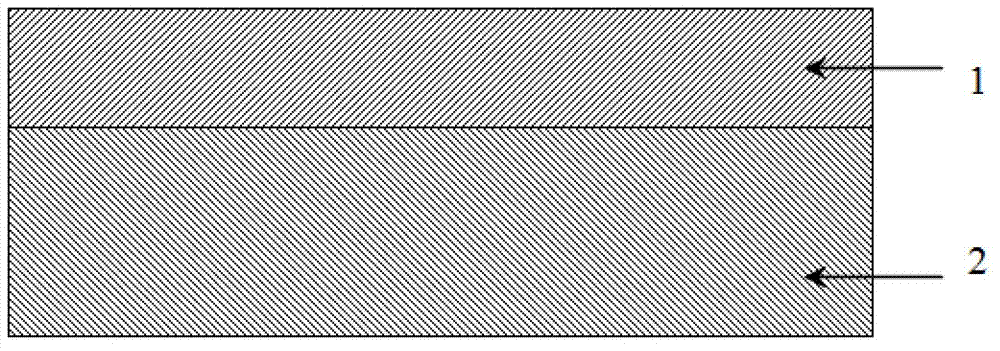

Image

Examples

Embodiment 1

[0025]Embodiment 1: The transparent layer 1 is EVA resin (purchased from DuPont Company of the United States, brand 150, VA content is 33%), and the thickness is 100 microns. The functional layer 2 is based on the transparent layer 1 resin with 5% titanium dioxide (purchased from DuPont, USA, TS-6200) added. A double-layer structure film containing the transparent layer 1 material and the functional layer 2 material was prepared by a co-extrusion casting process, wherein the thickness of the transparent layer 1 was 100 um, and the thickness of the functional layer 2 was 400 um. The upper protective material glass whiteboard (manufactured by Asahi Glass Co., Ltd., trade name Solyte), EVA adhesive film (Mitsui Chemicals Co., Ltd.), solar cell monomer, double-layer packaging adhesive film according to the present invention, and the lower protective material glass whiteboard (Asahi Glass Co., Ltd. Co., Ltd., trade name Solyte) are sequentially laminated and laminated to form a sol...

Embodiment 2

[0027] In Example 1, the resin of the transparent layer 1 and the functional layer 2 was changed to PVB, and it was the same as that of Example 1.

Embodiment 3

[0029] Change the transparent layer 1 resin in Example 1 to polyolefin POE (Mitsui Chemicals DF740), the functional layer 2 resin is to add 3% titanium black on the basis of the A layer resin, and the lower protective material in the solar cell module is changed It is a photovoltaic backplane (Suzhou Saiwu Applied Technology Co., Ltd., Cynagard121), except that it is the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com