Laminated packaging film for solar cell and solar cell module with packaging film

A solar cell and packaging film technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of low long-term reliability and low volume resistivity of components, and achieve favorable promotion, high water vapor barrier properties, and low moisture content. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

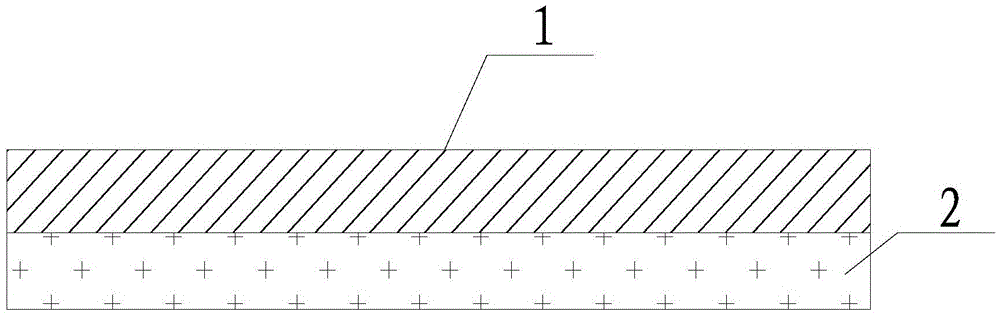

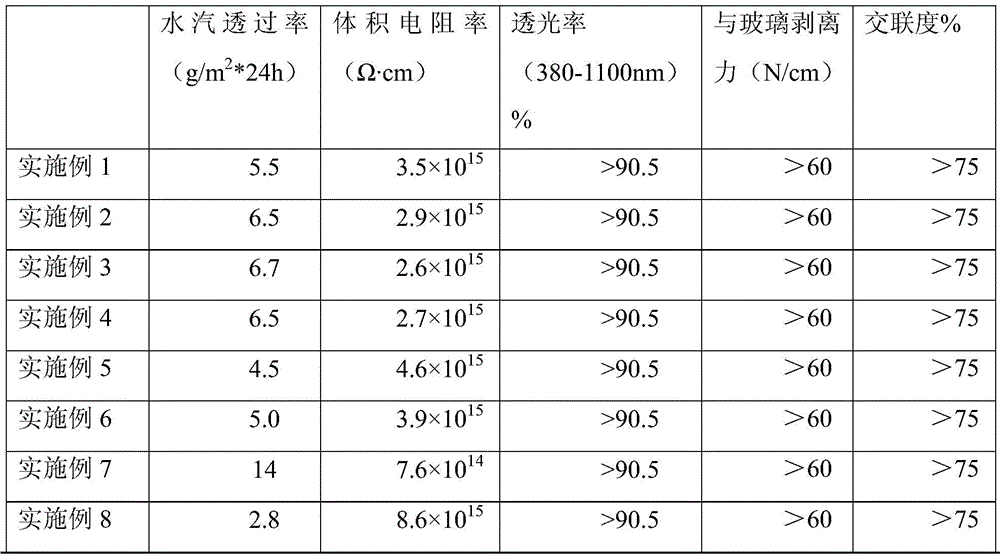

[0022] This embodiment provides a laminated packaging film for solar cells, which has a thickness of 450 μm, such as figure 1 As shown, it includes a first resin layer 1 and a second resin layer 2, the first resin layer 1 is covered on the upper surface of the second resin layer 2, and the materials of the first resin layer 1 and the second resin layer 2 are co-extruded form. The thickness of the first resin layer 1 is 150 μm, and the thickness of the second resin layer 2 is 300 μm. The first resin layer 1 is an EVA layer (TPC company, melt index 20g / 10min), and the second resin layer 2 is a POE layer (manufactured by DOW Company, melt index 18g / 10min).

Embodiment 2

[0024] This embodiment provides a kind of laminated packaging film for solar cells, which is basically the same as the packaging film in Example 1, except that the first resin layer 1 is an EVA layer (TPC company, melt finger 30g / 10min), The second resin layer 2 is a POE layer (manufactured by DOW, melt index 30g / 10min).

Embodiment 3

[0026] This embodiment provides a kind of laminated packaging film for solar cells, which is basically the same as the packaging film in Example 2, except that the first resin layer 1 is an EVA layer (TPC company, melt finger 5g / 10min), The second resin layer 2 is a POE layer (manufactured by DOW Company, melt index 5g / 10min).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com