OLED device and packaging method and packaging device thereof

A packaging method and a technology of a packaging device, which are applied in the manufacture of electric solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc., can solve problems such as low productivity, adverse effects of devices, and impact on packaging effects, so as to improve quality and life, and improve packaging effect, quick and easy separation of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment provides a packaging method for packaging an OLED device formed on a substrate, including: separating the graphene film formed on the copper foil from the copper foil, and packaging the OLED device with the graphene film.

[0055] This encapsulation method can give full play to the characteristics of high light transmittance, ultra-thin and flexible, high water and oxygen barrier and easy transfer between substrates (that is, easy to separate from copper foil and connect with OLED devices) of graphene film. The introduction into the packaging of OLED devices not only improves the packaging effect of OLED devices, but also simplifies the packaging process of OLED devices and improves production efficiency.

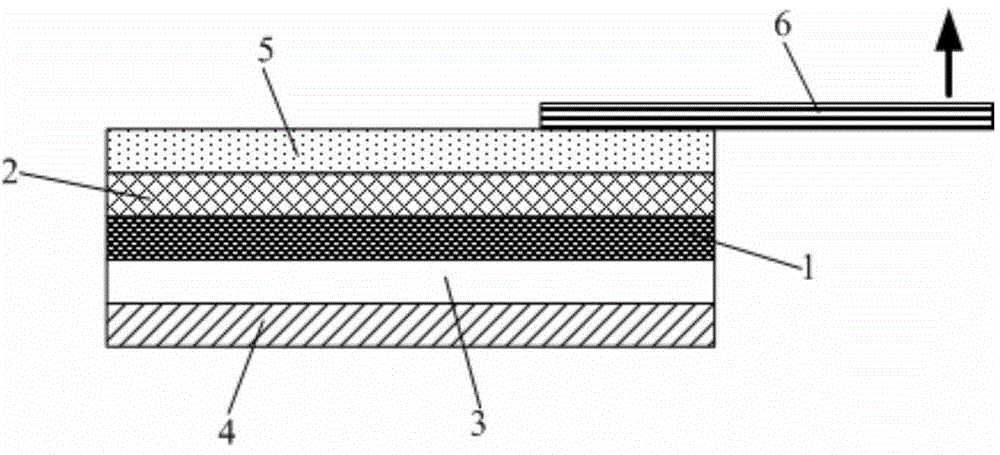

[0056] In this embodiment, the graphene film formed on the copper foil is separated from the copper foil, and the OLED device is packaged by using the graphene film, which specifically includes: figure 1 and figure 2 as shown,

[0057] Step S10: Bo...

Embodiment 2

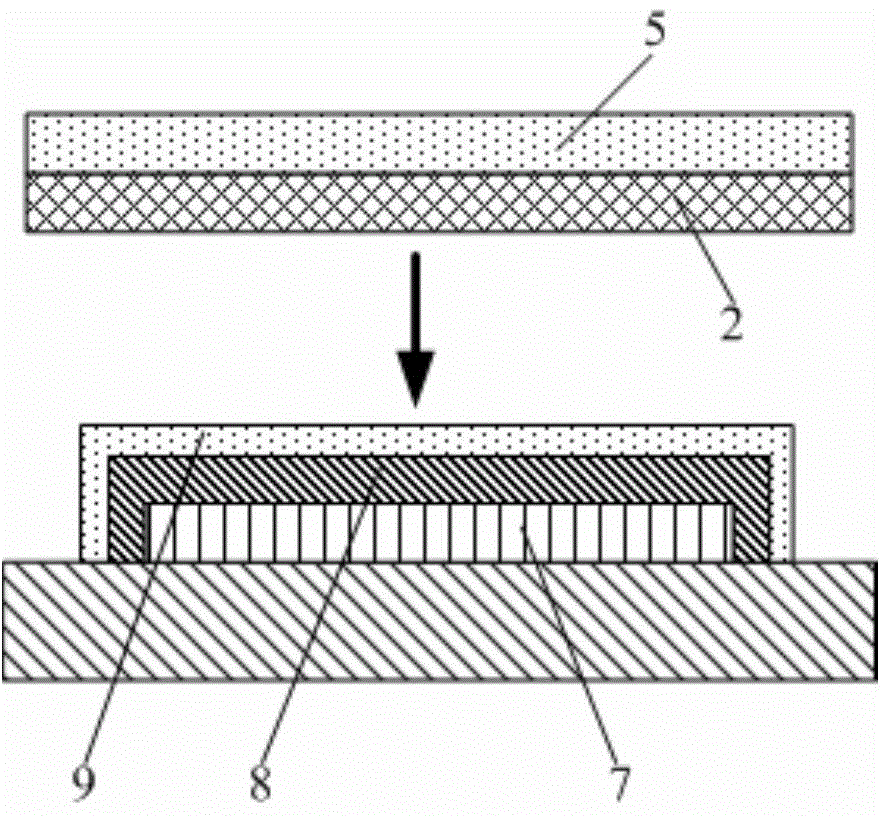

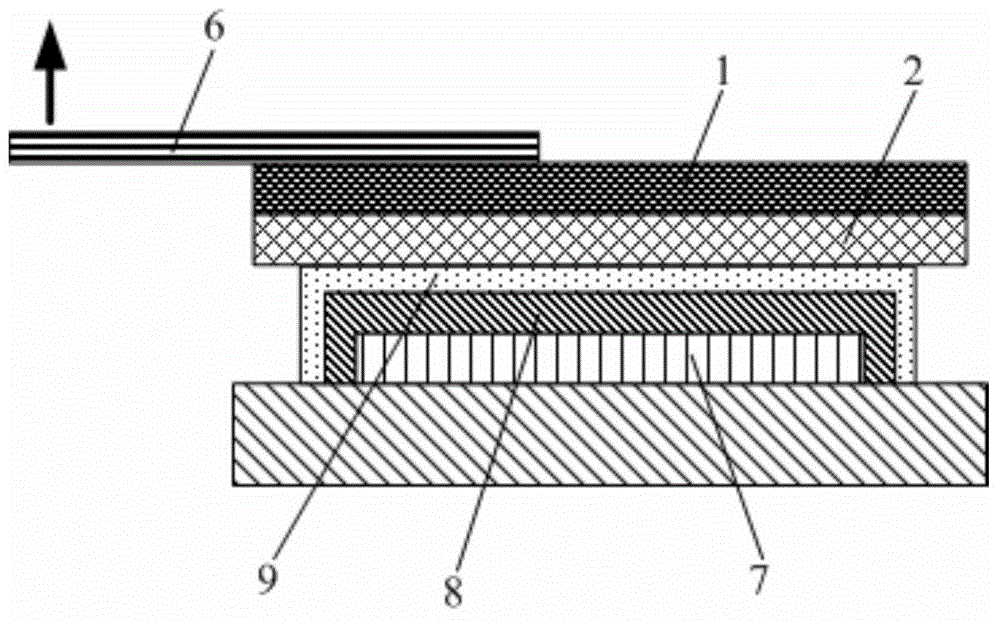

[0072] This embodiment provides a packaging method, which is different from Embodiment 1 in that the graphene film formed on the copper foil is separated from the copper foil, and the OLED device is packaged by using the graphene film, which specifically includes: image 3 and Figure 4 as shown,

[0073] Step S20 : forming a passivation layer 8 on the OLED device 7 , and coating a transparent glue 9 on the passivation layer 8 .

[0074] The material of the transparent glue 9 is the same as in Example 1. The material and formation method of the passivation layer 8 are the same as those in Embodiment 1.

[0075] Step S21 : before the transparent glue 9 is cured, stick the side of the copper foil 1 on which the graphene film 2 is formed on the transparent glue 9 .

[0076] Step S22: curing the transparent glue 9 .

[0077] The curing temperature of the transparent glue 9 is the same as in Example 1.

[0078] Step S23: Fixing the OLED device 7 completed in step S22, sticki...

Embodiment 3

[0086] This embodiment provides a packaging method. The difference from Embodiment 1-2 is that the graphene film formed on the copper foil is separated from the copper foil, and the OLED device is packaged by using the graphene film. Specifically include: Figure 5 as shown,

[0087] Step S30 : forming a passivation layer 8 on the OLED device 7 .

[0088] The material and formation method of the passivation layer 8 are the same as those in Embodiment 1.

[0089] Step S31 : attaching the side of the copper foil 1 on which the graphene film 2 is not formed on the heated roller 11 .

[0090] A heating device is arranged inside the roller 11 , and the heating device can heat the axial surface of the roller 11 .

[0091] Step S32 : fixing the base substrate 12 completed in step S30 on the base 13 , with the OLED device 7 facing away from the base 13 .

[0092] In this step, the base substrate 12 completed in step S30 is fixed on the base 13 by the adhesive method or the vacuum a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com