Preparation method of high-toughness equal-hole polymer hollow fiber separating membrane

A fiber separation and polymer technology, used in semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of poor toughness, wide pore size distribution, and inability to achieve high-precision separation of polymer flat membranes, and achieve implementation Simple steps, easy scale and effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Based on the above principles, a method for preparing a high-toughness homoporous polymer hollow fiber separation membrane of the present invention comprises the following steps:

[0030] (1) dissolving one or more than two block polymers, additives, and fillers in a mixed solvent containing at least one good solvent and at least one non-solvent to form a casting solution;

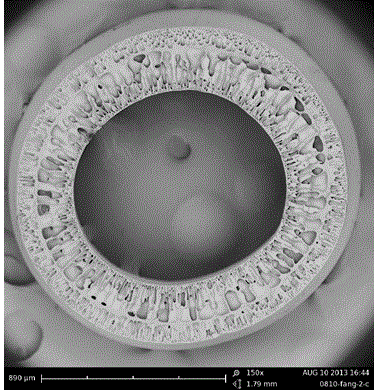

[0031] (2) forming the polymer tubular film through the spinning equipment through the casting solution;

[0032] (3) keeping the polymer tubular membrane in the air for 1-30s to form a polymer hollow fiber nascent membrane;

[0033] (4) The polymer hollow fiber nascent membrane is immersed in a coagulation bath, and the polymer hollow fiber nascent membrane is immersed in the coagulation bath for 2-60s to form a hollow fiber separation membrane of a solidified high-toughness homoporous polymer;

[0034] (5) Soak the solidified high-toughness homoporous polymer hollow fiber membrane in water or glyce...

Embodiment 1

[0045] A method for preparing a high-toughness homogeneous polymer hollow fiber separation membrane, the steps are as follows:

[0046] (1) Dissolve the block copolymer PAN-b-P2VP, polyvinylidene fluoride, and silica nanoparticles composed of polyacrylonitrile and 2-vinylpyridine in a mixed solution composed of tetrahydrofuran and dimethylformamide Form a homogeneous casting solution, wherein each composition is as follows:

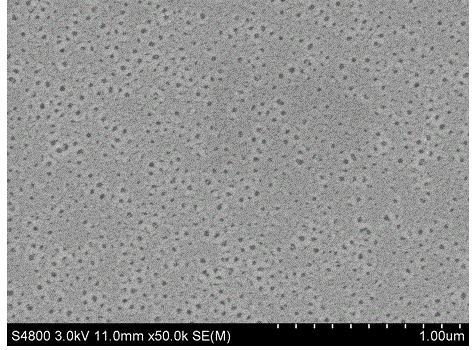

[0047] The mass volume fraction of the block copolymer composed of polyacrylonitrile and poly2-vinylpyridine in the casting solution is 100g / L, wherein the mass ratio of polyacrylonitrile and poly2-vinylpyridine in the block polymer 1:1, the molecular mass of polyacrylonitrile and poly 2-vinylpyridine block is 120000g / mol;

[0048] The mass volume fraction of polyvinylidene fluoride in the casting solution is 400g / L, and the molecular mass of polyvinylidene fluoride is 220000g / mol;

[0049] The mass volume fraction of silicon dioxide in the casting solu...

Embodiment 2

[0056] A method for preparing a high-toughness homogeneous polymer hollow fiber separation membrane, the steps are as follows:

[0057] (1) Dissolve the block copolymer PAN-b-P2VP, polyvinylidene fluoride and silica nanoparticles composed of polyacrylonitrile and poly 2-vinylpyridine in a mixed solution composed of tetrahydrofuran and dimethylformamide A homogeneous casting solution is formed in the medium, wherein each composition is as follows:

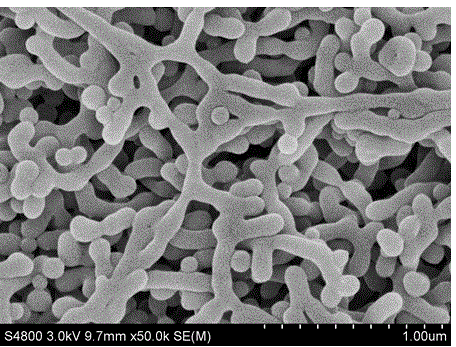

[0058] The mass volume fraction of the block copolymer composed of polyacrylonitrile and poly2-vinylpyridine in the casting solution is 400g / L, wherein the mass ratio of polyacrylonitrile and poly2-vinylpyridine in the block polymer 2:1, the molecular weights of polyacrylonitrile and poly-2-vinylpyridine are 100000g / mol and 50000g / mol respectively;

[0059] The mass volume fraction of polyvinylidene fluoride in the casting solution is 400g / L, and the molecular mass of polyvinylidene fluoride is 1015000g / mol;

[0060] The mass volu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com