Hot metal ladle and production line thereof

A technology for ladle and cover, which is applied in casting molten material containers, manufacturing tools, foundry workshops, etc., can solve the problems of no hook, uneven scattering, and large heat, and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

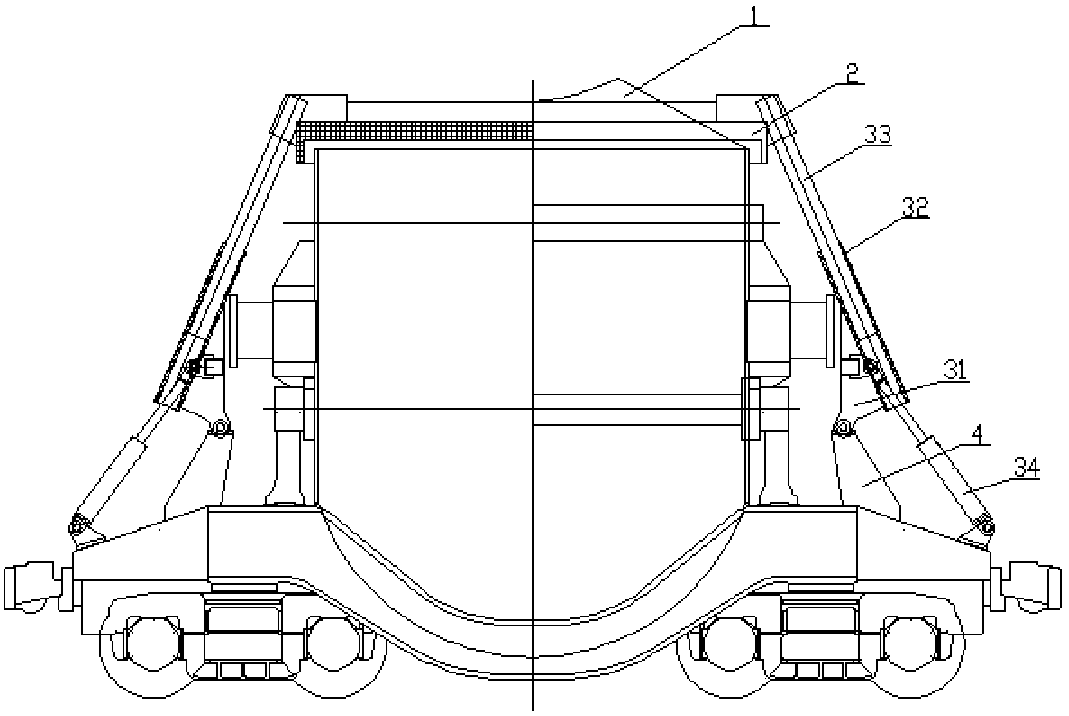

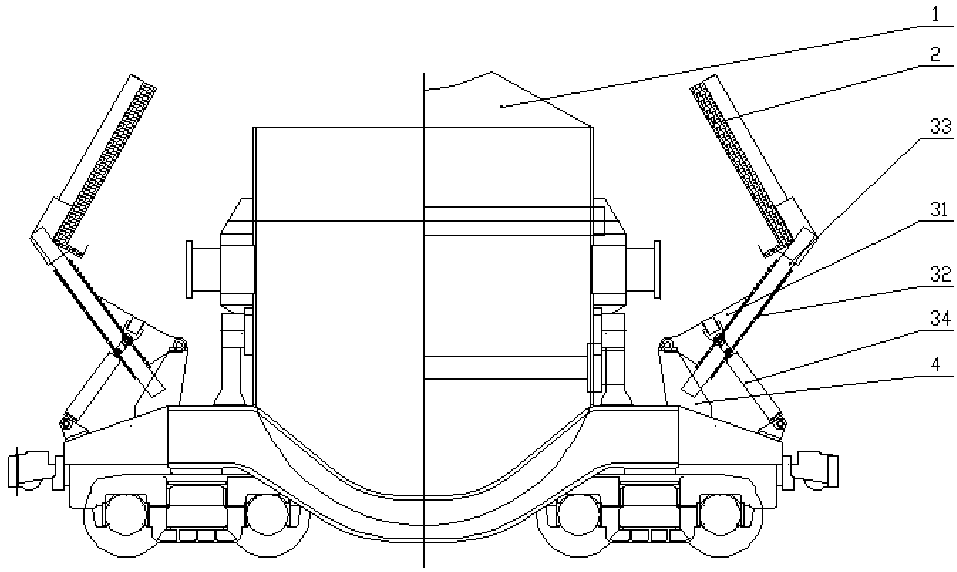

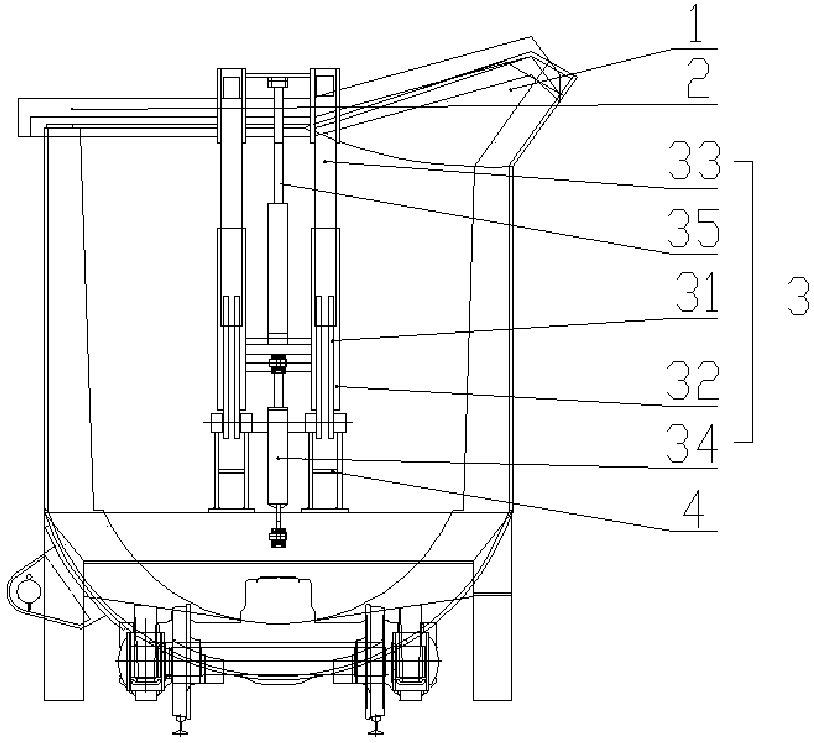

[0031] figure 1 A schematic structural view of the ladle provided by Embodiment 1 of the present invention; figure 2 for figure 1 Schematic diagram of the open state of the cover; image 3 for figure 1 side view of the Figure 1-Figure 3 As shown, the ladle provided by Embodiment 1 of the present invention includes a ladle body 1, a cover 2 and a lifting device 3;

[0032] The ladle body 1 upper cover is equipped with two said ladle covers 2, and said ladle body 1 is equipped with a lifting device 3 connected with each said ladle cover 2 respectively;

[0033] The lifting device 3 includes a rotating arm 31, a guide sleeve 32, a telescopic rod 33, a first telescopic thrust mechanism 34 and a second telescopic thrust mechanism 35, the rotating arm 31 is installed on the ladle body 1, and the guide The sleeve 32 is installed on the rotating arm 31, the telescopic rod 33 is installed in the guide sleeve 32, the telescopic rod 33 is connected with the cover 2, and the first ...

Embodiment 2

[0043] The ladle provided in this embodiment two is a further improvement to the ladle provided in embodiment one, in embodiment one and Figure 1-Figure 3 On the basis of the above, the ladle provided in the second embodiment includes a ladle body 1, a cover 2 and a lifting device 3;

[0044] The ladle body 1 upper cover is equipped with two said ladle covers 2, and said ladle body 1 is equipped with a lifting device 3 connected with each said ladle cover 2 respectively;

[0045] The lifting device 3 includes a rotating arm 31, a guide sleeve 32, a telescopic rod 33, a first telescopic thrust mechanism 34 and a second telescopic thrust mechanism 35, the rotating arm 31 is installed on the ladle body 1, and the guide The sleeve 32 is installed on the rotating arm 31, the telescopic rod 33 is installed in the guide sleeve 32, the telescopic rod 33 is connected with the cover 2, and the first telescopic thrust mechanism 34 is connected with the rotating arm 32. The arm 31 is co...

Embodiment 3

[0060] The ladle provided in this embodiment three is a further improvement to the ladle provided in embodiment one, in embodiment one and Figure 1-Figure 3 On the basis of the above, the ladle provided by the present embodiment three includes a ladle body 1, a cover 2 and a lifting device 3;

[0061] The ladle body 1 upper cover is equipped with two said ladle covers 2, and said ladle body 1 is equipped with a lifting device 3 connected with each said ladle cover 2 respectively;

[0062] The lifting device 3 includes a rotating arm 31, a guide sleeve 32, a telescopic rod 33, a first telescopic thrust mechanism 34 and a second telescopic thrust mechanism 35, the rotating arm 31 is installed on the ladle body 1, and the guide The sleeve 32 is installed on the rotating arm 31, the telescopic rod 33 is installed in the guide sleeve 32, the telescopic rod 33 is connected with the cover 2, and the first telescopic thrust mechanism 34 is connected with the rotating arm 32. The arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com