Method for separating and refining arteannuin, dihydro-artemisinic acid and artemisinic acid by reversed-phase high performance liquid chromatography

A reversed-phase high-efficiency liquid phase, dihydroartemisinic acid technology, applied in the separation/purification of hydroxyl compounds, organic chemistry, etc., can solve the problems of discarding and resource waste, achieve large sample loading, increase production, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

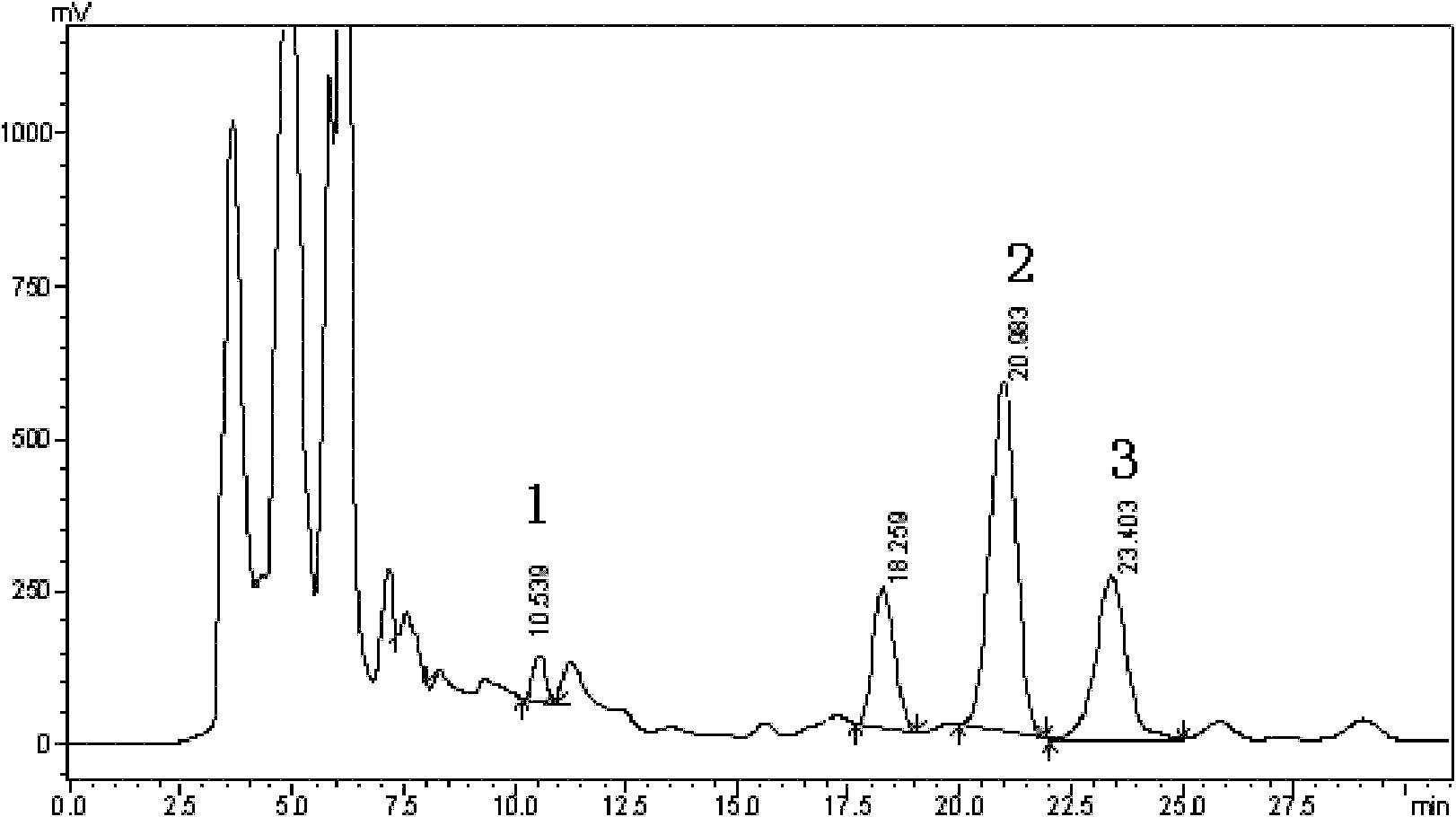

[0021] Weigh 100g dry sample of Artemisia annua, add 800mL of petroleum ether, reflux and extract at 60°C for 3 times, each time for 1h, combine the extracts, filter, and recover petroleum ether in vacuo to obtain 4.6g of crude extract, add 1.15mL of acetonitrile to resuspend, vacuum Suction filtration, the filtrate is passed through a 0.45 μm microporous filter membrane, and the preparative high-performance liquid chromatography adopts the following preparative chromatographic conditions: with Shimadzu PRC-ODS, reversed-phase column, internal diameter 20mm, length 250mm; Mobile phase is acetonitrile / water ( The volume ratio is 60:40); the flow rate is 15 mL / min; the detection wavelength is 192 nm; the column temperature is 40° C.; the injection volume is 400 μL. At the same time, artemisinin, artemisinic acid and dihydroartemisinic acid standards were prepared into solutions, and the artemisinin, artemisinic acid and dihydroartemisinic acid determined under the same chromatogr...

Embodiment 2

[0023] Weigh 200g of dried Artemisia annua, add 1.6L of petroleum ether, reflux and extract at 60°C for 3 times, each time for 1h, combine the extracts, filter, and recover petroleum ether in a vacuum to obtain 9.4g of crude extract, add 2.35mL of acetonitrile to resuspend, Vacuum suction filtration, pass the filtrate through a 0.45 μm microporous membrane, and apply the preparative high-performance liquid chromatography, using the following preparative chromatographic conditions: use Shimadzu PRC-ODS, reversed-phase column, inner diameter 30mm, length 250mm; mobile phase is acetonitrile / water (The volume ratio is 60:40), the flow rate is 40 mL / min; the detection wavelength is 192 nm; the column temperature is 40° C.; the injection volume is 800 μL. At the same time, artemisinin, artemisinic acid and dihydroartemisinic acid standards were prepared into solutions, and the artemisinin, artemisinic acid and dihydroartemisinic acid determined under the same chromatographic conditio...

Embodiment 3

[0025] Weigh 500g dry sample of Artemisia annua, add 4L petroleum ether, reflux and extract at 60°C for 3 times, each time for 1h, combine the extracts, filter, and recover petroleum ether in vacuo to obtain 24.6g crude extract, add 6.15ml acetonitrile to resuspend, vacuum Suction filtration, pass the filtrate through a 0.45 μm microporous filter membrane, and put it on a preparative high-performance liquid chromatography column, adopt the following preparation chromatographic conditions: use Shimadzu PRC-ODS, reversed-phase column, internal diameter 50mm, length 250mm; mobile phase is acetonitrile / water (The volume ratio is 60:40), the flow rate is 100 mL / min; the detection wavelength is 192 nm; the column temperature is 40° C.; the injection volume is 2 mL. At the same time, artemisinin, artemisinic acid and dihydroartemisinic acid standards were prepared into solutions, and the artemisinin, artemisinic acid and dihydroartemisinic acid determined under the same chromatographi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com