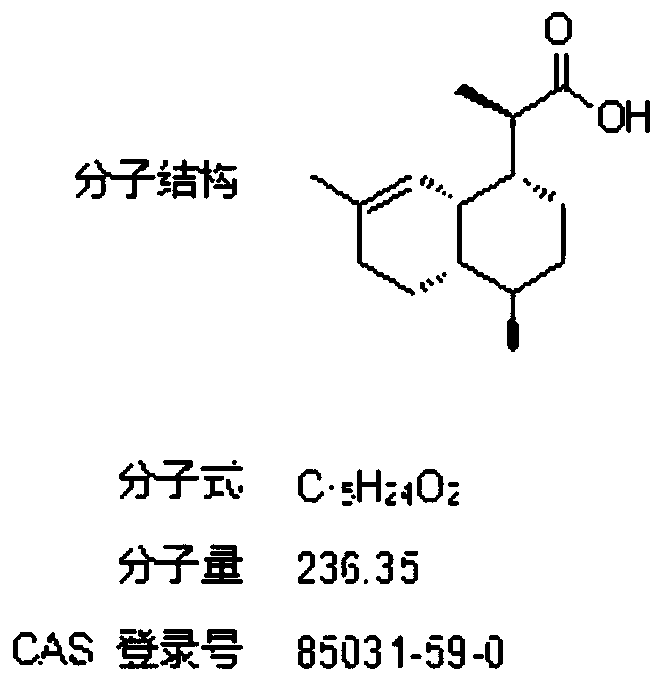

Method for preparing high-purity dihydroartemisinic acid by removing grease from crude dihydroartemisinic acid

A high-purity technology of dihydroartemisinic acid, which is applied in the separation/purification of carboxylic acid compounds, organic chemistry and other directions, can solve the problems affecting the purity of dihydroartemisinic acid, high oil impurities, etc., and achieves easy industrialization and promotion, The effect of removing grease impurities and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing high-purity dihydroartemisinic acid by removing oil from crude dihydroartemisinic acid, comprising the following steps:

[0041](1) Primary crystallization: using 100 g of crude dihydroartemisinic acid with a content of 30.0% as a raw material, add 10 ml of methanol with a volume concentration of 50%, stir for 0.5 h, and stand for 48 h to crystallize;

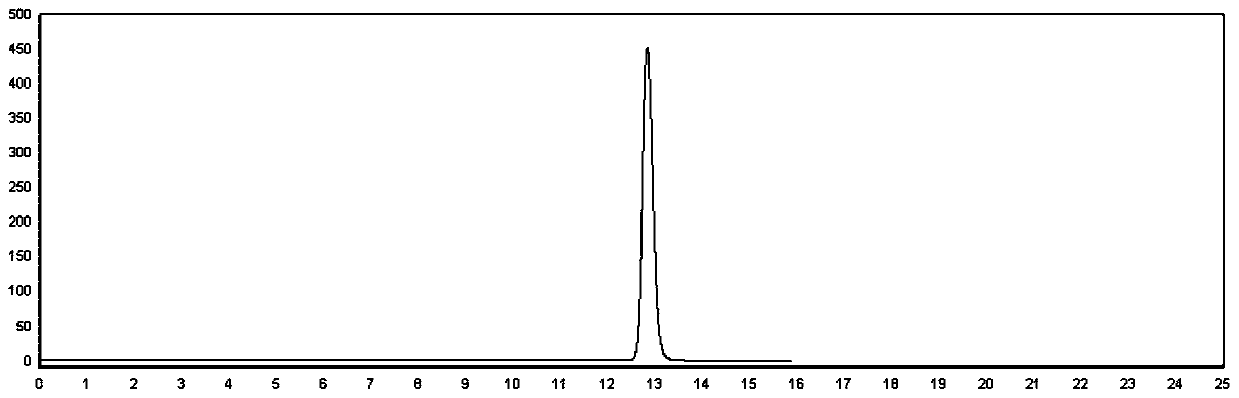

[0042] (2) Centrifugal deoiling: centrifuge after the crystalline liquid crystallization in step (1) is complete, the filter cloth mesh number during described centrifugation is 100 orders, and the rotating speed is 700r / min, and centrifugation time is 4h, obtains off-white crystal and grease, The oil was repeated 4 times according to step (1), and combined to obtain 37.1 g of off-white crystals; the content of dihydroartemisinic acid in the obtained off-white crystals was 73% as detected by HPLC;

[0043] (3) Dissolving and deoiling: Add 742ml of methanol with a volume concentration of 50% to the ...

Embodiment 2

[0049] A method for preparing high-purity dihydroartemisinic acid by removing oil from crude dihydroartemisinic acid, comprising the following steps:

[0050] (1) Primary crystallization: 10 kg of crude dihydroartemisinic acid with a content of 32.5% was used as raw material, 5 L of n-butanol with a volume concentration of 60% was added, stirred for 1 hour, and left to stand for 24 hours to crystallize;

[0051] (2) Centrifugal deoiling: centrifuging after the crystalline liquid crystallization in step (1) is complete, the filter cloth mesh number during described centrifugation is 200 orders, and the rotating speed is 1400r / min, and centrifugation time is 3h, obtains off-white crystallization and grease, The fats and oils were repeated twice according to step (1), and 3.65 kg of off-white crystals were obtained by merging; the content of dihydroartemisinic acid in the obtained off-white crystals was 78% as detected by HPLC;

[0052] (3) Dissolving and deoiling: Add 54.75 L of...

Embodiment 3

[0058] A method for preparing high-purity dihydroartemisinic acid by removing oil from crude dihydroartemisinic acid, comprising the following steps:

[0059] (1) Primary crystallization: take 1000 kg of crude dihydroartemisinic acid with a content of 31.2% as raw material, add 1000 L of a mixture of ethyl acetate and industrial hexane with a volume concentration of 70% and a volume ratio of 2:1, and stir for 1.5 h , standing for 72h to crystallize;

[0060] (2) Centrifugal deoiling: centrifuge after the crystalline liquid crystallization in step (1) is complete, the filter cloth mesh number during described centrifugation is 400 orders, and the rotating speed is 2100r / min, and centrifugation time is 2h, obtains off-white crystal and grease, The fats and oils were repeated once according to step (1) to obtain 365.9 kg of off-white crystals; the content of dihydroartemisinic acid in the obtained off-white crystals was 81.2% as detected by HPLC;

[0061] (3) Dissolving and deoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com