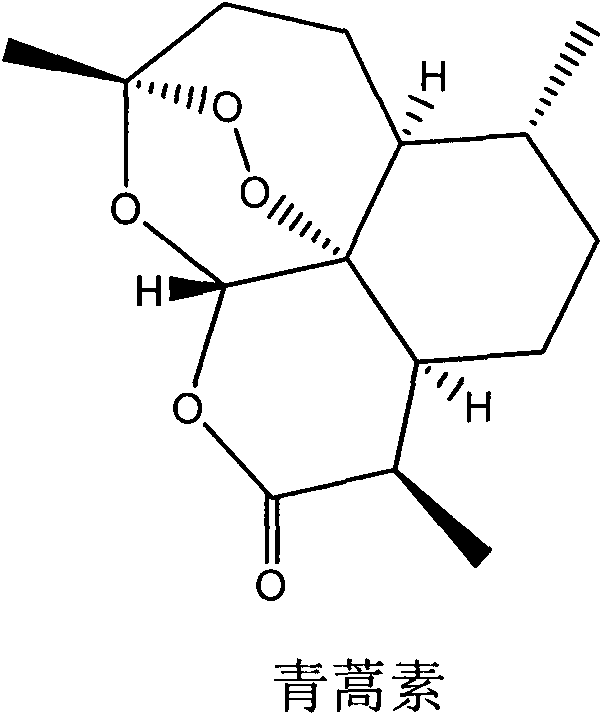

Preparation method of artemisinin

A technology of artemisinin and artemisinic acid, applied in the direction of organic chemistry and the like, can solve the problems of difficulty in realizing industrialized production, unsuitable for large-scale production, and low industrialization prospects, and achieves low cost, easy large-scale production, and simple post-processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The invention discloses a preparation method of artemisinin, and those skilled in the art can learn from the content of this article and appropriately improve the process parameters to realize it. It needs to be pointed out that all similar replacements and modifications are obvious to those skilled in the art, and they are all considered to be included in the present invention, and relevant personnel can obviously make changes without departing from the content, spirit and scope of the present invention. Changes or appropriate changes and combinations are made to the content described herein to realize and apply the technology of the present invention.

[0020] In the present invention, unless otherwise specified, the scientific and technical terms used herein have the meanings commonly understood by those skilled in the art.

Embodiment 1

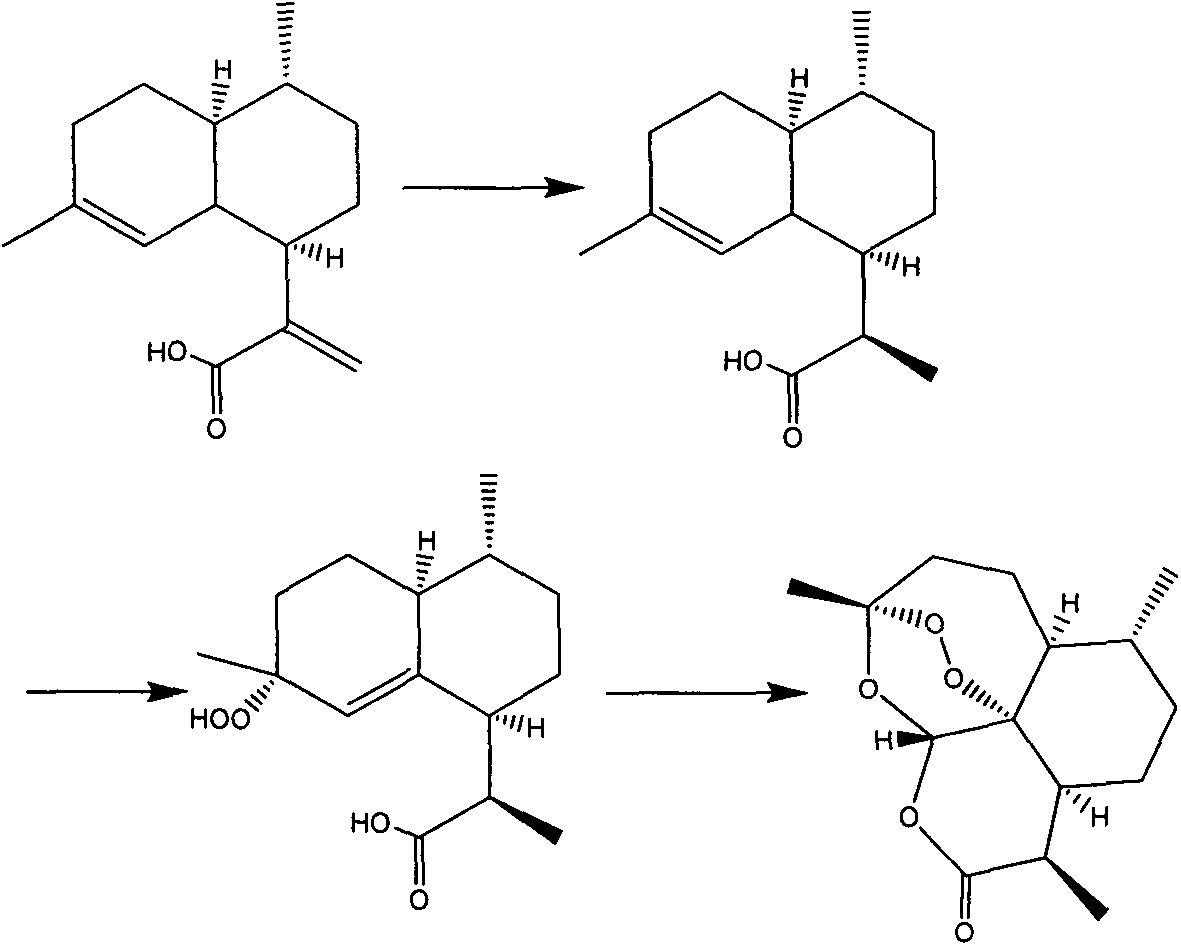

[0023] Dissolve 100 g (0.43 mol) of artemisinic acid in 800 mL of chloroform, and react overnight at room temperature with a hydrogen pressure of 1 bar and 1.5 g of palladium carbon as a catalyst, filter with diatomaceous earth, wash with chloroform, and recover the solvent under reduced pressure to obtain a solid product Dihydroartemisinic acid 99g (0.42mol), yield 98%.

[0024] Dissolve 100g (0.42mol) of dihydroartemisinic acid in 500mL of acetone, use 105g (0.44mol) of sodium molybdate as a catalyst, and slowly add 30% hydrogen peroxide dropwise at -10°C as an oxidizing agent 150mL (about 1.32mol ), reacted for 24 hours, filtered, extracted three times with 200mL dichloromethane, and the organic phase was dried over anhydrous sodium sulfate.

[0025] Take the above reaction solution, lower the temperature to 0°C, add 200g (0.55mol) copper trifluoromethanesulfonate, feed oxygen, monitor the reaction progress, after the reaction is completed, filter, rinse with dichloromethan...

Embodiment 2

[0027] Dissolve 100g (0.43mol) of artemisinic acid in 1000mL of tetrahydrofuran, at room temperature, hydrogen pressure 2bar, 5.5g of Raney nickel as a catalyst, react overnight, filter with diatomaceous earth, wash with ethyl acetate, and recover the solvent under reduced pressure, 96 g (0.41 mol) of solid product dihydroartemisinic acid was obtained, and the yield was 95%.

[0028] Dissolve 100g (0.42mol) dihydroartemisinic acid in 500mL isopropanol, use 105g (0.44mol) sodium molybdate as a catalyst, and slowly add 30% hydrogen peroxide dropwise at -10°C as an oxidizing agent 150mL (approx. 1.32mol), reacted for 24 hours, filtered, extracted three times with 200mL dichloromethane, and dried the organic phase with anhydrous sodium sulfate.

[0029] Take the above reaction solution, lower the temperature to 0°C, add 180g (0.50mol) copper trifluoromethanesulfonate, feed oxygen, monitor the reaction progress, after the reaction is completed, filter, rinse with dichloromethane, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com