Separation of sihydroartemisinic acid from artemisinin production waste by means of alkali dissolution and acid deposition

A technology of dihydroartemisinic acid and production waste, which is applied in the separation/purification of carboxylic acid compounds, organic chemistry and other directions, can solve the problems of waste of resources, high cost of industrialized development, etc., achieve high recovery rate, improve extraction efficiency and The effect of high recovery rate and production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

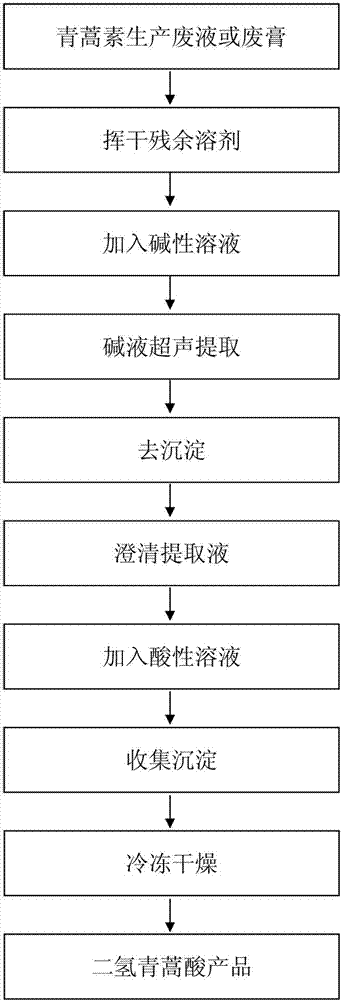

Method used

Image

Examples

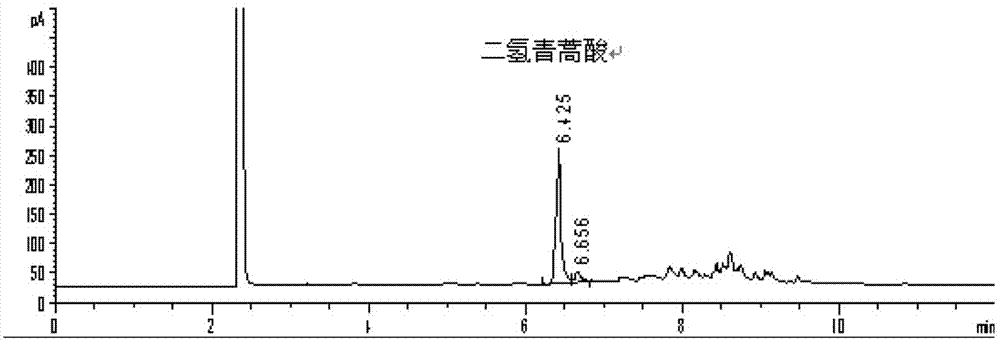

Embodiment 1

[0017] Take 20L of artemisinin production waste liquid, concentrate in vacuum at 33°C until the organic solvent evaporates to dryness, add 450mL of methanol, concentrate in vacuum at 40°C until the solution is completely evaporated, weigh the residue, weigh 2.3Kg; add 11.5L to achieve a mass volume concentration of 0.2% 80 watts of sodium hydroxide solution, 80 watts of ultrasonic extraction twice, ultrasonic temperature is 50 ℃, 60min each time, the two extracts are combined, and centrifuged at 3000rpm at room temperature for 10min, to remove the precipitate, collect the supernatant, and obtain a clarified extract solution. Add 1mol / L hydrochloric acid solution to the extraction solution, and keep stirring until the pH value of the solution is 4.5, place it at room temperature until the precipitate is completely precipitated, pour off the supernatant, collect the precipitate, wash the precipitate twice with 150 mL distilled water, and wash the precipitate Pre-freeze at -21°C f...

Embodiment 2

[0020] Take 5kg of artemisinin production waste paste, add 410mL of absolute ethanol, concentrate in vacuo at 40°C until the solvent is completely evaporated, weigh the residue, weighing 3.7Kg; add 11.1L of sodium bicarbonate solution with a mass volume concentration of 0.6%, 90W Ultrasonic extraction 2 times, 50min each time, the ultrasonic temperature is 45 ℃, combined the 2 extracts, centrifuged at 3000rpm at room temperature for 12min, to remove the precipitate, collect the supernatant to obtain a clarified extract solution; add 0.5mol / L to the clarified extract solution sulfuric acid solution, and kept stirring until the pH value of the solution was 3.2, placed at room temperature until the precipitate was completely precipitated, poured off the supernatant, collected the precipitate, rinsed the precipitate twice with 190mL distilled water, and pre-frozen the washed precipitate at -21°C for 15h. Vacuum freeze-drying until the moisture content of the product is lower than 1...

Embodiment 3

[0022]Take 4 kg of artemisinin production waste paste, add 350 mL of methanol, concentrate in vacuo at 33°C until the solvent evaporates completely, weigh the residue, weighing 2.9Kg; Ultrasonic extraction 2 times, 45min each time, the ultrasonic temperature is 40 ℃, combine the 2 extracts, centrifuge at 3000rpm at room temperature for 15min, remove the precipitate, collect the supernatant to obtain a clarified extract, add 2mol / L of Phosphoric acid solution, and keep stirring until the pH value of the solution is 1.0, place it at room temperature until the precipitate is completely precipitated, pour off the supernatant, collect the precipitate, rinse the precipitate twice with 150mL distilled water, pre-freeze the washed precipitate at -21°C for 24h, vacuum Freeze-dry until the moisture content of the product is lower than 1%, and the product of dihydroartemisinin is obtained. The product weighs 72.5g, and the detection by gas chromatography (the method is the same as in Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com