A soil improver

A technique for improving slag and surfactants, applied in the field of slag improving agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

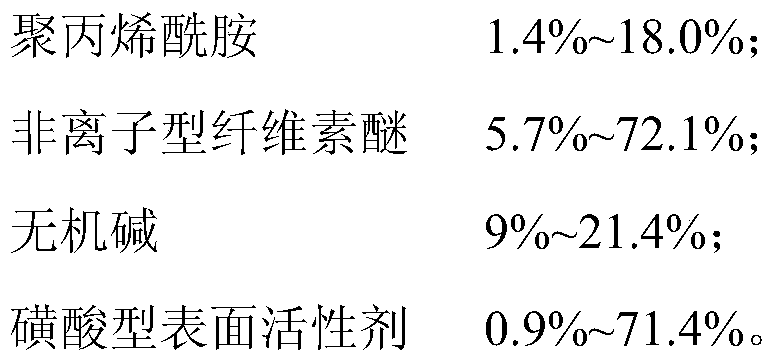

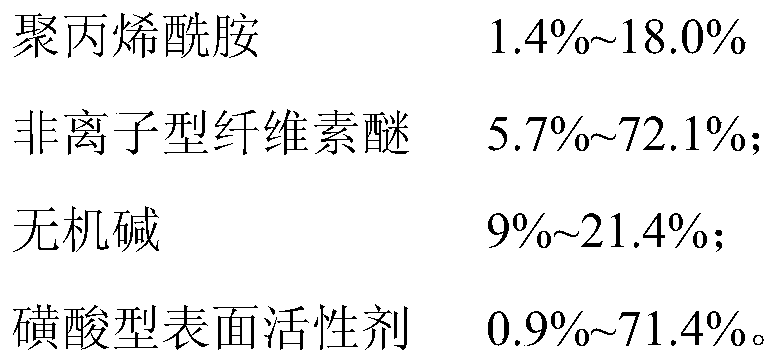

[0032] The second aspect of the present invention provides a method for preparing the aforementioned dregs modifier, comprising: mixing polyacrylamide, nonionic cellulose ether and inorganic base with water, and then adding a sulfonic acid surfactant.

[0033] More specifically, mix polyacrylamide, non-ionic cellulose ether and inorganic alkali solid; stir water in a stirring tank at a speed of 1000-1200 rpm; mix the mixed non-ionic cellulose ether and inorganic alkali very slowly and continuously Add water, stir for at least 20 minutes, then add sulfonic acid surfactant, stir for at least 5 minutes, until the solids are completely dissolved; let stand for 90 minutes to complete the preparation.

[0034] The third aspect of the present invention provides the use of the aforementioned slag soil modifier in the construction of sand and pebble formations.

[0035] The purpose of muck improvement is that the soil is in a plastic flow state with certain viscosity, fluidity and impe...

Embodiment 1

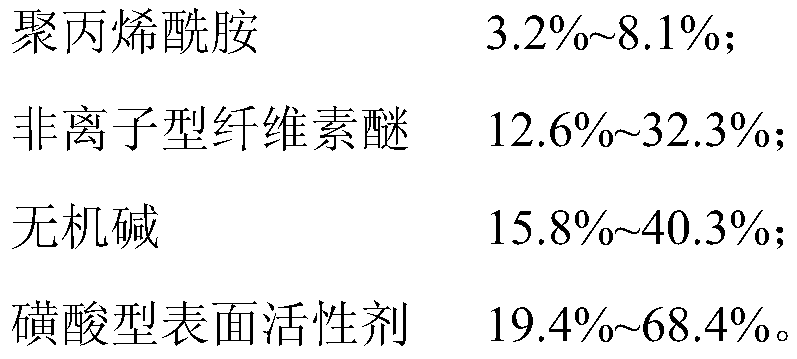

[0039] Mix the polyacrylamide of mass fraction 8.1%, the hydroxyethyl cellulose of 32.3% and the magnesium hydroxide solid of 40.3%; Prepare water according to the ratio of mass ratio polyacrylamide: water=1:250, mix water Stir in the tank at a speed of 1000-1200rpm; add the mixed hydroxyethyl cellulose and magnesium hydroxide to the water very slowly and continuously, stir for at least 20 minutes, then add 19.4% naphthalenesulfonic acid formaldehyde condensate, stir for at least 5 minutes, until solid Completely dissolved; stand for 90min to complete the preparation.

Embodiment 2

[0041]Mix the polyacrylamide of mass fraction 5.8%, the hydroxyethyl cellulose of 23.3% and the magnesium hydroxide solid of 29.1%; Prepare water according to the ratio of mass ratio acrylamide: water=1:250, put water in stirring tank Stir at a speed of 1000-1200rpm; add the mixed hydroxyethyl cellulose and magnesium hydroxide to the water very slowly and continuously, stir for at least 20min, then add 41.9% naphthalenesulfonic acid formaldehyde condensate, stir for at least 5min, until the solid is completely Dissolve; stand for 90min to complete the preparation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com