Low-temperature degrading method of halogenous plastic

A plastic and low-temperature technology, applied in the degradation of halogen-containing plastics, low-temperature degradation of halogen-containing plastics, can solve the problems of high reaction temperature, waste liquid, high energy consumption, etc., achieve great economic value, reduce energy consumption, and avoid equipment The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

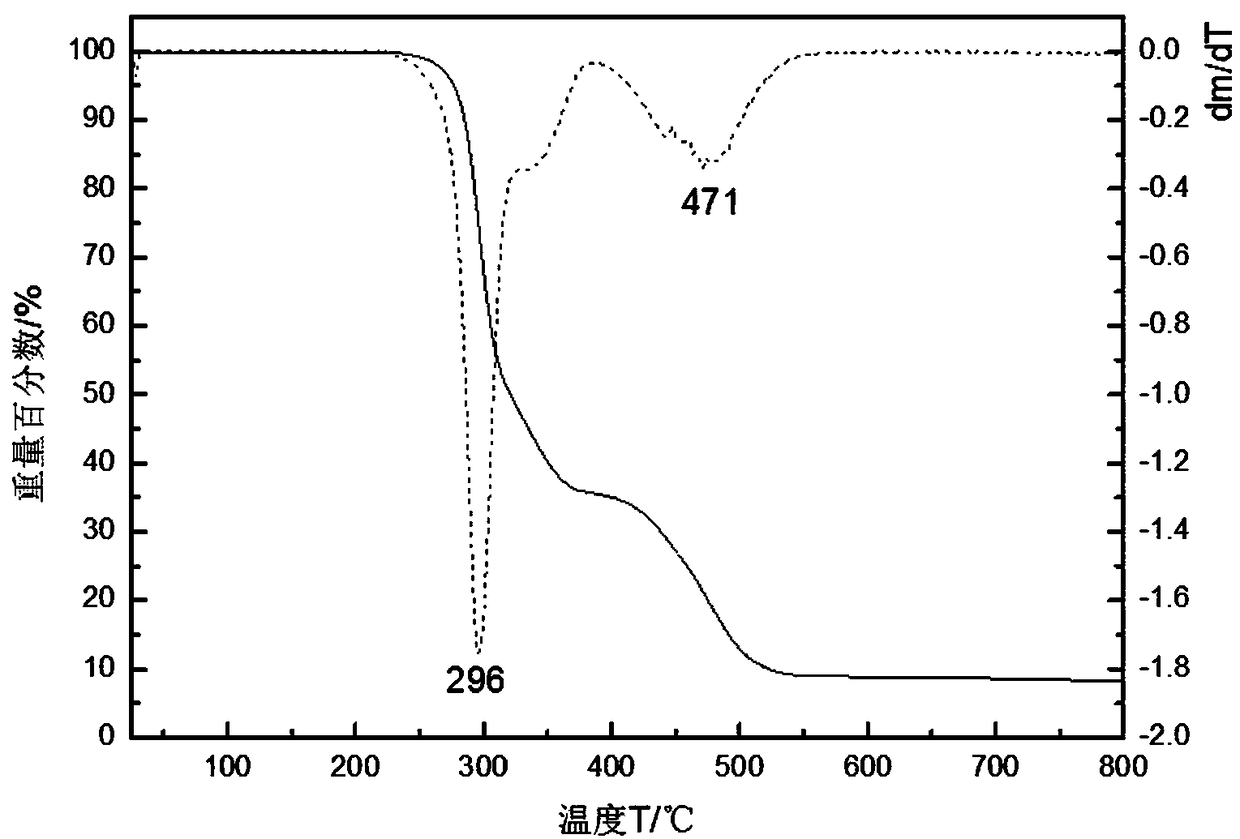

[0034] A low-temperature degradation method for halogen-containing plastics. Put 1.5g of PVC, 1.0g of aluminum powder, 0.05g of aluminum trichloride, 0.05g of iodine, and 10g of carbon tetrachloride into a three-necked flask containing magnetons, and place them at 58°C After the reaction, the solution was purple-red (the color of iodine dissolved in carbon tetrachloride) at the beginning of the reaction, and after 10 minutes, the solution turned purple-black with a small amount of white smoke; Larger and more (violent reaction) and the solution turns into pure black; after 31 minutes, the reaction solution is viscous; and because of the condensing device, only the gas with a relatively low boiling point can be discharged; the gas discharged when the hydrogen is not passed can make the Acidic potassium permanganate fades, and the gas discharged after passing hydrogen gas can make silver nitrate form white precipitate, which will release a large amount of heat in an instant after...

Embodiment 2

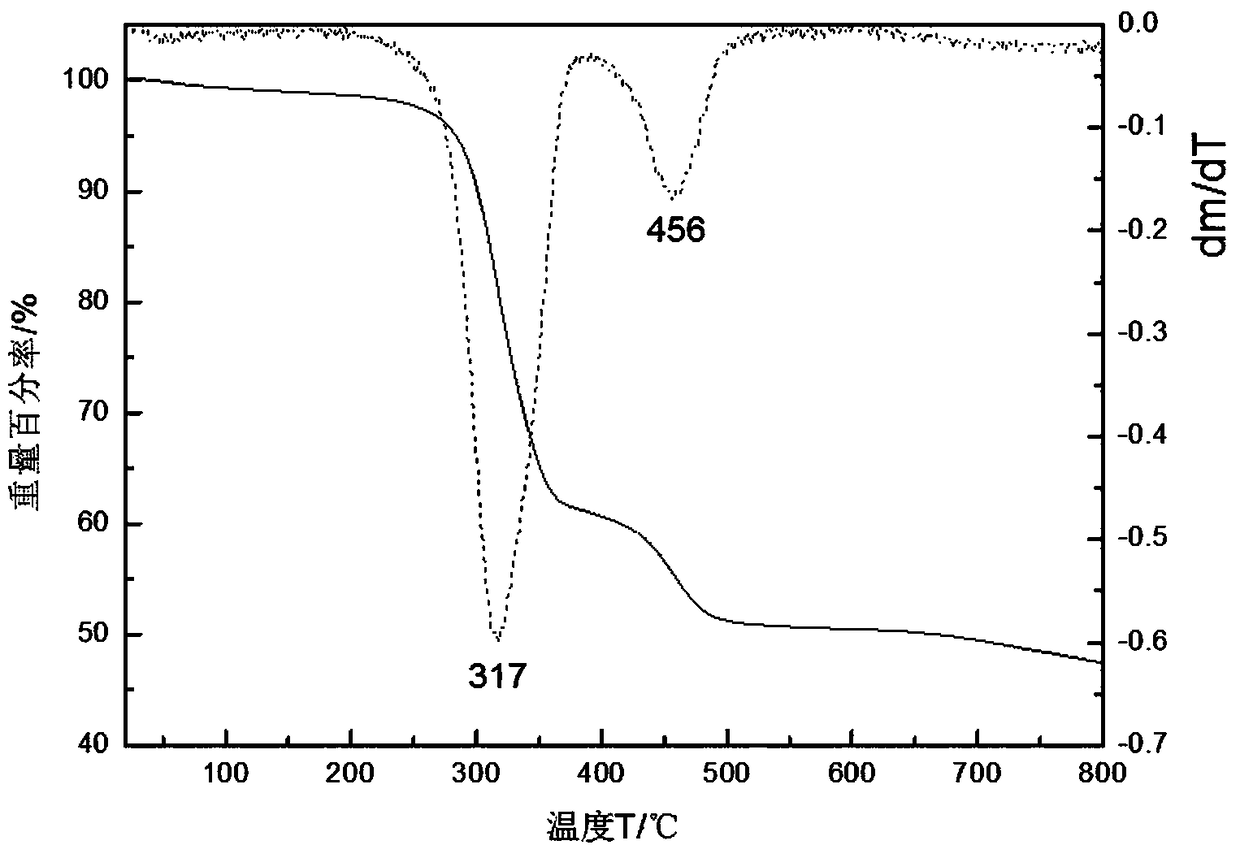

[0050] A low-temperature degradation method for halogen-containing plastics. Put 1.5g of PVC, 1.0g of aluminum powder, 0.025g of aluminum trichloride, 0.025g of iodine, and 10g of bromoethane into a three-necked flask containing magnets, and put them under the condition of 58°C reaction, the solution was orange at the beginning of the reaction, and there were bubbles, which disappeared after 30s; after 19min, the PVC in the bottle swelled, and the surface formed a solid, and the color was brown; after 25min, the reactant in the bottle turned into pure black; 41min When the reaction is finished, the gas discharged when the hydrogen is not passed can discolor the acidic potassium permanganate; the gas discharged after the hydrogen is passed cannot cause the silver nitrate to form a white precipitate; as the distillation progresses, there are yellow solids on the wall of the three-necked flask, and the inside of the bottle There is a large amount of white smoke, and a distillate f...

Embodiment 3

[0054] A low-temperature degradation method for halogen-containing plastics. Put 1.5g PVC, 1.0g aluminum powder, 0.035g aluminum trichloride, 0.035g iodine, 7g bromoethane and 3g carbon tetrachloride into a three-necked flask containing magnetons , reacted at 58°C, the solution was pink-purple at the beginning of the reaction; after 7 minutes, the bottle began to bubble and the color became darker; after 16 minutes, the color turned into pure black with a small amount of white smoke. 48min reaction ended. And because there is a condensing device, only the gas with a relatively low boiling point can be discharged. The gas discharged when hydrogen is not passed can discolor the acidic potassium permanganate. The gas discharged after passing hydrogen can make silver nitrate form white precipitate. As the distillation progressed, there were yellow solids on the wall of the three-neck flask, and there was a lot of white smoke in the bottle. At 70 ° C, a fraction flowed out, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

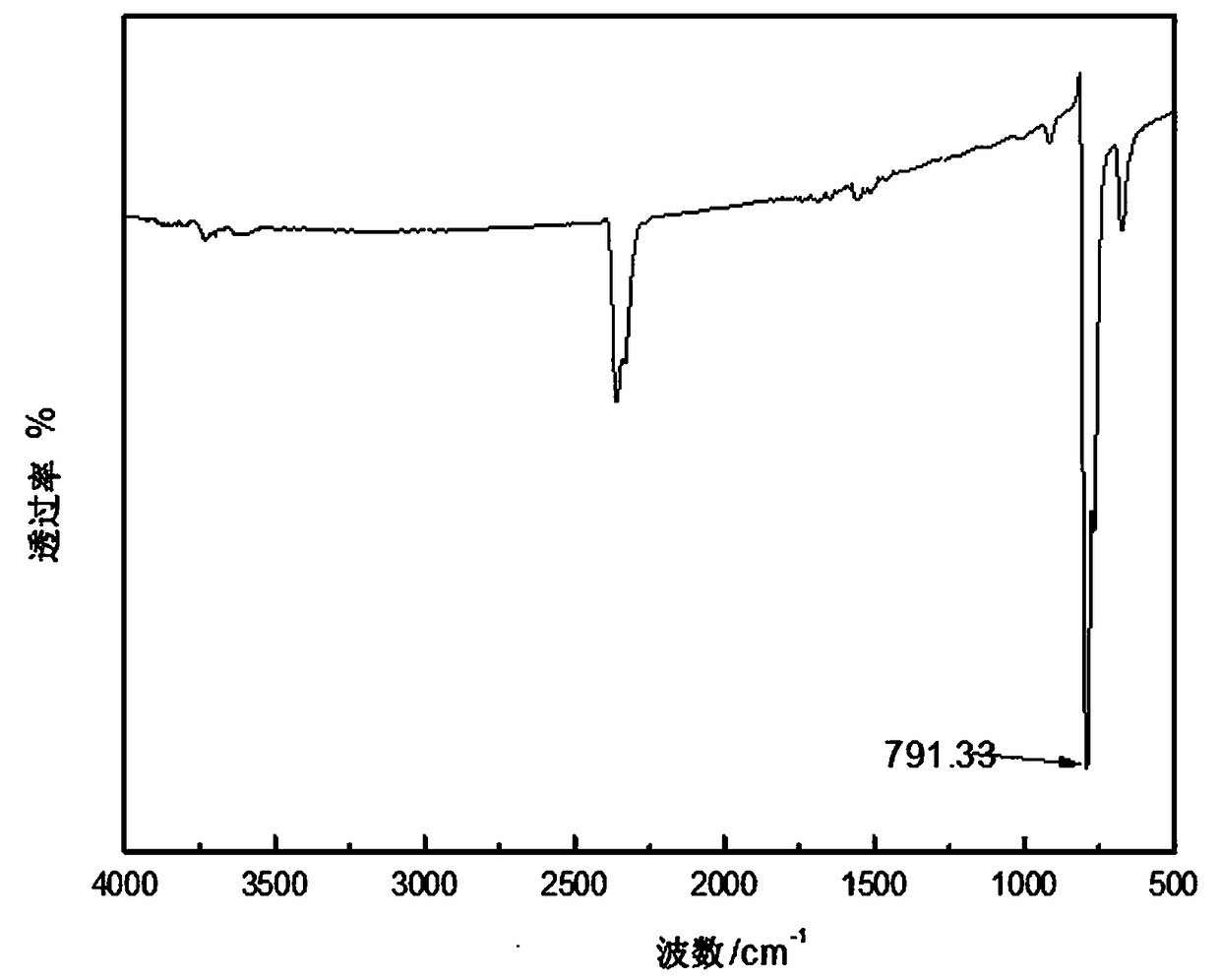

| Wave number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com