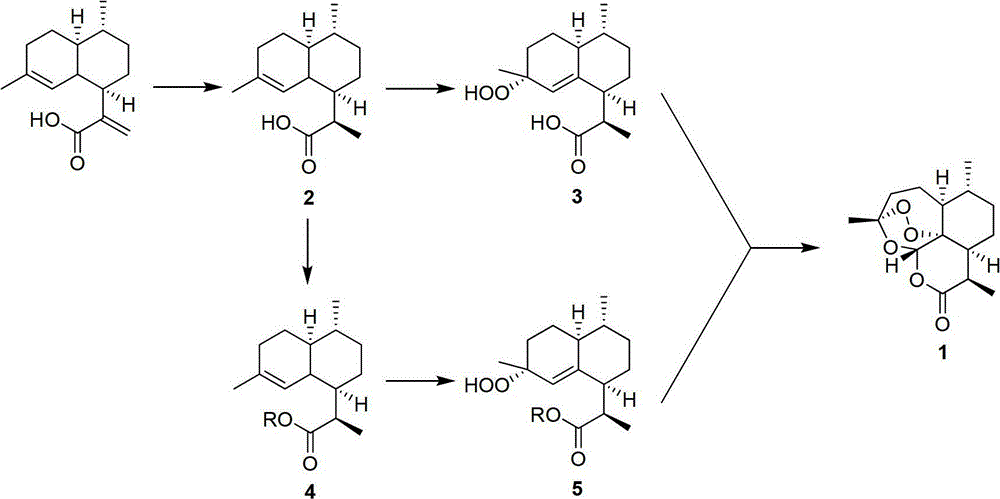

Method for preparing artemisinin through arteannuic acid

A technology of artemisinic acid and artemisinin, applied in the field of biomedicine, can solve the problems of unfavorable environmental protection and industrial production, cumbersome operation, poor product selectivity, etc., and achieve easy large-scale production, good stereoselectivity, and high product purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

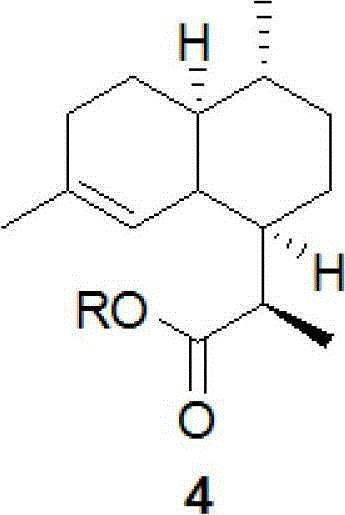

[0042] (1) Synthesis of dihydroartemisinic acid 2

[0043] Artemisinic acid (100 g, 427 mmol) and 10% Pd / C (4.3 mmol) were added to 1000 mL of methanol, and reacted at -50 °C in a hydrogen atmosphere (1 bar) for 24 hours. The reaction mixture was filtered through celite, and the organic solvent was removed by rotary evaporation to obtain a white solid (99 g, 98%).

[0044] (2) Synthesis of dihydroartemisinic acid 3 peroxide

[0045] Dihydroartemisinic acid (99 g, 420 mmol), potassium dichromate (4.2 mmol), potassium carbonate (4.2 mmol) were added to 1000 mL of acetonitrile. At -78°C, slowly add 30% hydrogen peroxide (420 mmol) dropwise to the system, and react overnight. The organic solvent was removed by rotary evaporation, the residual phase was extracted with ethyl acetate (500mL×3), the combined organic phases were dried over anhydrous sodium sulfate, filtered by suction, the solvent was removed by rotary evaporation, and the product was directly put into the next react...

Embodiment 2

[0049] (1) Synthesis of dihydroartemisinic acid 2

[0050] Artemisinic acid (100 g, 427 mmol) and 10% Pd / C (427 mmol) were added to 1000 mL of isopropanol, and reacted at 25 °C in a hydrogen atmosphere (1 bar) for 12 hours. The reaction mixture was filtered through celite, and the organic solvent was removed by rotary evaporation to obtain a white solid (100 g, 99%).

[0051] (2) Synthesis of dihydroartemisinic acid 3 peroxide

[0052] Dihydroartemisinic acid (100 g, 424 mmol), sodium perchlorate (424 mmol), and pyridine (424 mmol) were added to 1000 mL of acetone. At -78°C, 30% hydrogen peroxide (4.2 mol) was slowly added dropwise to the reaction mixture and reacted overnight. The organic solvent was removed by rotary evaporation, the residual phase was extracted with ethyl acetate (500mL×3), the combined organic phases were dried over anhydrous sodium sulfate, filtered by suction, the solvent was removed by rotary evaporation, and the product was directly put into the next...

Embodiment 3

[0056] (1) Synthesis of dihydroartemisinic acid 2

[0057] Artemisinic acid (100g, 427mmol), Al 2 o 3 / Rh (4.3mmol) was added into 1000mL of methanol, and reacted at -50°C in a hydrogen atmosphere (1 bar) for 24 hours. The reaction mixture was filtered through celite, and the organic solvent was removed by rotary evaporation to obtain a white solid (99 g, 98%).

[0058] (2) Synthesis of dihydroartemisinic acid 3 peroxide

[0059] Dihydroartemisinic acid (99 g, 420 mmol), sodium hypochlorite (4.2 mmol), sodium hydroxide (4.2 mmol) were added to 1000 mL of acetonitrile. At -40°C, 30% hydrogen peroxide (420 mmol) was slowly added dropwise to the system, and reacted overnight. The organic solvent was removed by rotary evaporation, the residual phase was extracted with ethyl acetate (500mL×3), the combined organic phases were dried over anhydrous sodium sulfate, filtered by suction, the solvent was removed by rotary evaporation, and the product was directly put into the next re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com