Method for preparing pentaerythritol and dipentaerythritol

A technology of dipentaerythritol and monopentaerythritol, which is applied in the field of preparation of pentaerythritol, can solve the problems of low total yield of monopentaerythritol and dipentaerythritol, low yield of dipentaerythritol, complex reaction process, etc., achieve high total yield and reduce production cost , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

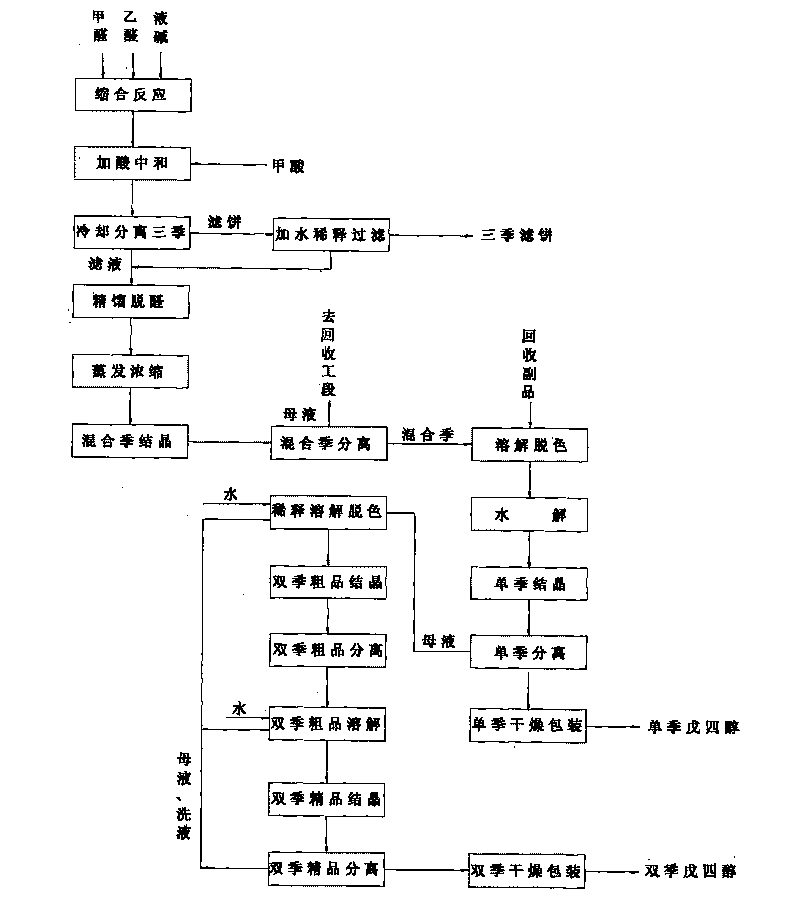

[0051] Example 1: Preparation method of monopentaerythritol and dipentaerythritol, see attached figure 1 .

[0052] The reaction was carried out at a molar ratio of formaldehyde: acetaldehyde: sodium hydroxide = 5.5:1: 1.12, the acetaldehyde feeding amount was 15 Kmol, and the entire feeding time was 120 minutes. Add 10.5m formaldehyde solution with a temperature of 25℃ and a concentration of 15g / 100ml in the reactor 3 , And then add sodium hydroxide solution, acetaldehyde solution and the remaining formaldehyde solution while stirring and the reaction liquid is circulated with a pump. In the first 40 minutes, add 330L of sodium hydroxide solution with a concentration of 30g / 100ml, Two put 670L of 30g / 100ml sodium hydroxide solution in 40 minutes, put 1240L of 30g / 100ml sodium hydroxide solution in the third 40 minutes, and start adding acetaldehyde after 10 minutes of sodium hydroxide solution , 1650L of acetaldehyde solution with a concentration of 40g / 100ml was uniformly pour...

Embodiment 2

[0058] Example 2: Preparation method of monopentaerythritol and dipentaerythritol, see attached figure 1 .

[0059] The reaction was carried out at a molar ratio of formaldehyde: acetaldehyde: sodium hydroxide = 5.0:1:1.10, the feeding amount of acetaldehyde was 15Kmol, and the feeding time was 120 minutes. Add 10m formaldehyde solution with a temperature of 20℃ and a concentration of 15g / 100ml in the reactor in advance 3 , And then add sodium hydroxide solution, acetaldehyde solution and the remaining formaldehyde solution while stirring and the reaction solution is circulated with a pump. In the first 40 minutes, add 500L of sodium hydroxide solution with a concentration of 25g / 100ml. Two put 940L of 25g / 100ml sodium hydroxide solution in 40 minutes, put 1200L of 25g / 100ml sodium hydroxide solution in the third 40 minutes, and start adding acetaldehyde after 10 minutes of sodium hydroxide solution , 2640L of acetaldehyde solution with a concentration of 25g / 100ml is evenly put...

Embodiment 3

[0065] Example 3: Preparation method of monopentaerythritol and dipentaerythritol, see attached figure 1 .

[0066] The reaction was carried out at a molar ratio of formaldehyde: acetaldehyde: sodium hydroxide = 4.5:1: 1.08, the feeding amount of acetaldehyde was 20 Kmol, and the feeding time was 150 minutes. Add 15.8m formaldehyde solution with a temperature of 18℃ and a concentration of 13g / 100ml in the reactor in advance 3 , And then add sodium hydroxide solution, acetaldehyde solution and the remaining formaldehyde solution while stirring and the reaction solution is circulated with a pump. In the first 50 minutes, add 600L of sodium hydroxide solution with a concentration of 15g / 100ml. In the second 50 minutes, put in 1600L of sodium hydroxide solution with a concentration of 15g / 100ml, and put in 3560L of sodium hydroxide solution with a concentration of 15g / 100ml in the third 50 minutes, and start to add B after 10 minutes of sodium hydroxide solution. Aldehyde, 2933L of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com