Split aluminum band on-line trimming apparatus

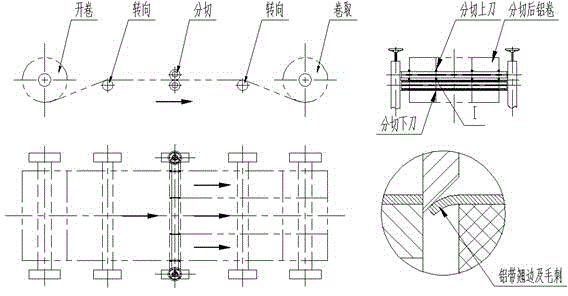

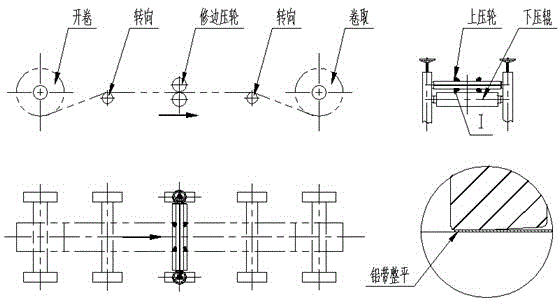

An aluminum strip and trimming technology, which is applied to the field of on-line trimming devices for slitting aluminum strips, can solve the problems of restricting production, high production costs, and declining yields, so as to reduce waste, improve comprehensive yields, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

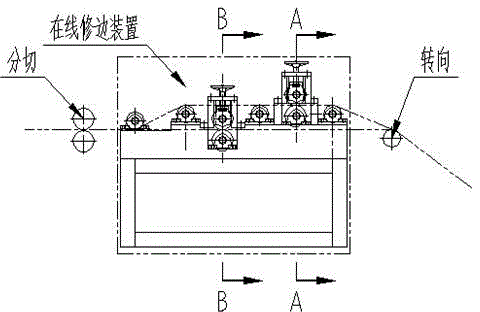

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] Such as Figure 3 to Figure 6 As shown, an online trimming device for slitting aluminum strips is composed of an upper pressing wheel 1, a lower pressing wheel 2, a wall panel 3, a shaft 4, a frame 5, a guide key 6, a set screw 7, and an adjusting hand wheel 8 , lead screw 9, outer spherical ball bearing with guide groove 10 and outer spherical ball bearing 11, wall panels 3 are fixedly installed on both sides of the frame 5, and the upper end of the wall panel 3 is provided with a screw rod 9, a screw rod 9 The upper end of the upper end is fixedly equipped with an adjustment hand wheel 8; the shaft 4 has two shafts, which are fixedly installed between the wall panels 3 up and down. The shaft 4 is fixedly connected with the wallboard 3 through the outer spherical ball bearing 11. The shaft 4 is respectively provided with guide keys 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com