Forging machining method for super-large titanium alloy forging stock

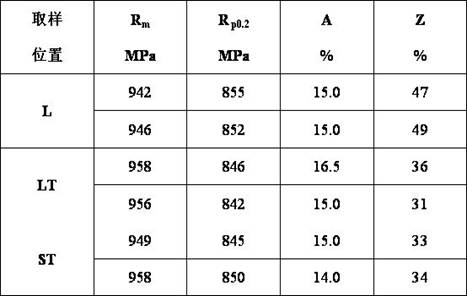

A technology with super-large specifications and processing methods, which is applied in the field of titanium alloy forging, can solve problems such as anisotropy of mechanical properties, large size, and uneven structure, so as to consolidate the uniformity and consistency of the structure, reduce the residual stress difference, increase the The effect of heart forging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 (200*1800*3500mm specification forging billet forging method)

[0029] Choose TC4 titanium alloy Φ880mm specification ingot casting, ingot β transformation temperature T β is 1000°C.

[0030] Step 1: Heat the TC4 ingot to 1150°C for heat preservation, and the heat preservation coefficient in this step is 0.7~0.75min / mm.

[0031] Step 2: Carry out blank forging for the ingot processed in step 1. The forging method is to forge the Φ880mm ingot with 2 upsetting and 2 drawing in the first fire to a square □900mm, and use air cooling after forging; the accumulated in this step The total deformation is not less than 80%, and the final forging temperature is not lower than 850°C.

[0032] Step 3: heat and keep the blank obtained in step 2 at 1080°C, and the heat preservation coefficient in this step is 0.7~0.75min / mm.

[0033] Step 4: Carry out 2 upsetting and 2 drawing of the ingot processed in step 3, and forge it to a flat square size of □800×1000×L mm, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com