Catalyst for producing propylene and propane by converting ethanol and its preparation method and application

A catalyst, ethanol technology, applied in chemical instruments and methods, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of unsatisfactory catalyst activity stability, low yields of propylene and propane, etc., and achieve good activity and stability. , The effect of high total yield and high single-pass yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

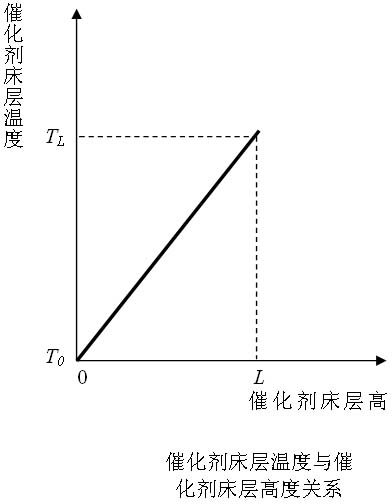

[0027] Catalytic properties of HZSM-5 / SAPO-34 composite molecular sieve catalysts with different ratios prepared by mixing method to catalyze ethanol conversion to propylene under different reaction conditions. The preparation method of HZSM-5 / SAPO-34 composite molecular sieve catalyst is as follows: a certain amount of HZSM-5 (SiO 2 / Al 2 o 3 =50, molar ratio) molecular sieve powder and a certain amount of SAPO-34 molecular sieve powder are evenly mixed to make a HZSM-5 / SAPO-34 composite molecular sieve catalyst, which is pressed into tablets and pulverized into 20-40 mesh particles, and used for ethanol to propylene reaction. The mass ratios of HZSM-5 / SAPO-34 in the catalyst are 1, 2, 3, 4 and 5 respectively; the catalysts are recorded as Cat-1, Cat-2, Cat-3, Cat-4 and Cat-5 respectively. image 3 It is the X-ray diffraction pattern of the composite molecular sieve catalyst.

[0028]Cat-1, Cat-2, Cat-3, Cat-4 and Cat-5 catalysts are used in ethanol to propylene reaction, ...

Embodiment 2

[0032] The preparation of HZSM-5 / SAPO-34 composite molecular sieve catalyst by hydrothermal method and the situation when the prepared catalyst is used in ethanol to propylene reaction under various reaction conditions. The process of preparing HZSM-5 / SAPO-34 composite molecular sieve by hydrothermal method is as follows: a certain amount of water glass (SiO 2 content is 30 wt%), phosphoric acid (H 3 PO 4 , the content is 85 wt%), pseudo-boehmite (AlOOH), tetraethylammonium hydroxide (TEAOH, content 25 wt%), and deionized water are fully mixed under the condition of rapid stirring, and the SiO in the above mixture 2 : Al 2 o 3 :P 2 o 5 : SiO 2 :TEAOH=1 : 1 : 0.3 : 2.0 : 50.0, the pH of the mixture is 6.5. Then, a certain amount of HZSM-5 (SiO 2 / Al 2 o 3 =50, molar ratio) powder, and stir quickly to make it evenly mixed. By adjusting the added amount of HZSM-5, the ratio of HZSM-5 and SAPO-34 in the synthesized HZSM-5 / SAPO-34 composite molecular sieve was contro...

Embodiment 3

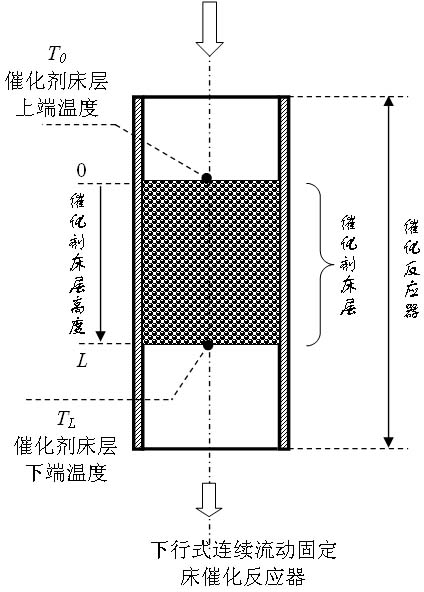

[0036] The reactions of ethanol to propylene using a catalyst bed with a temperature gradient and an isothermal catalyst bed are described respectively. The catalyst used is the Cat-4 catalyst prepared by the method described in Example 1. The reaction conditions for ethanol conversion on the catalyst bed with temperature distribution are: the temperature at the upper end of the catalyst bed is 510°C, and the temperature at the lower end of the catalyst bed is 550°C. The catalyst bed temperature gradient was 16 °C / cm, normal pressure, ethanol partial pressure was 20 kPa, and the total flow rate was 80 mL / min. The reaction conditions for ethanol conversion on an isothermal catalyst bed are: reaction temperature 550 °C, normal pressure, ethanol partial pressure 20 kPa, total flow rate 80 mL / min, the yield of propane, propylene and other products in the above process changes with time as attached Figure 5 shown. By adopting the technical solution provided by the invention, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com