Impregnating method of preparing isostatic pressing graphite product

A technology of graphite products and isostatic pressing, which is applied in the field of preparation of static-pressed graphite products, can solve problems such as uneven release, influence of product impregnation uniformity and surface smoothness, uneven pitch, etc., to avoid thermal expansion and contraction effects , uniform impregnation and smooth surface, improving the overall yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

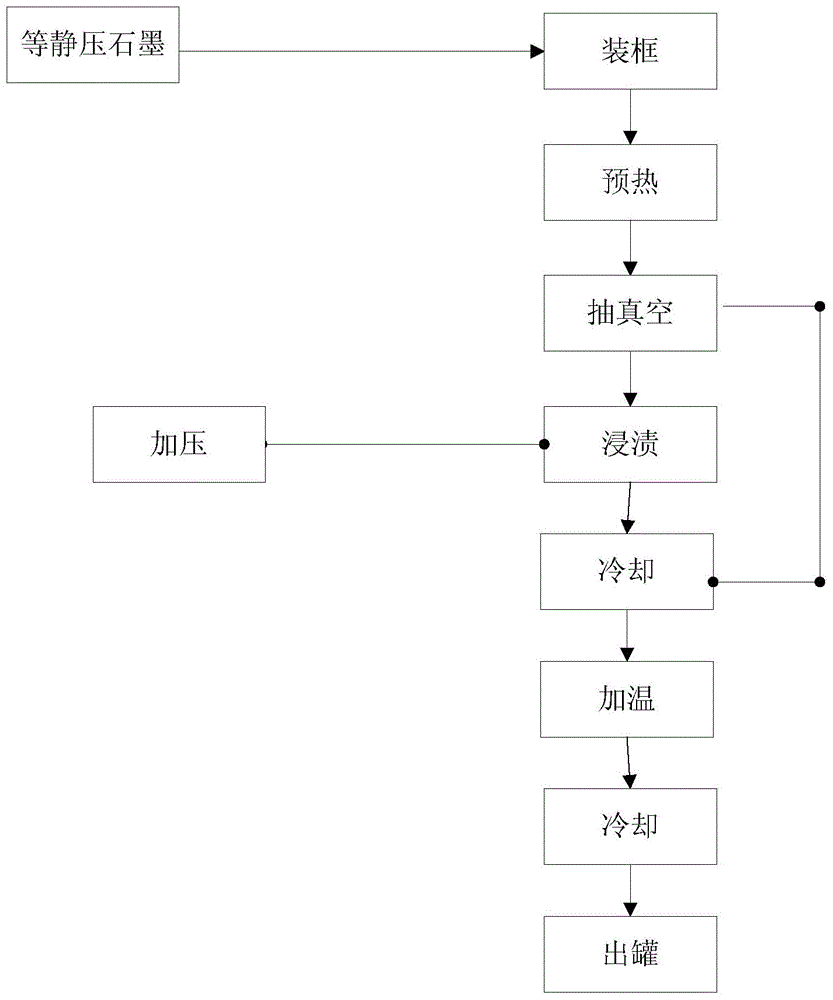

Method used

Image

Examples

Embodiment 1

[0035]The isostatic graphite product was heated freely from room temperature to 180°C for 3 hours, then raised to 210°C at a rate of 10°C / h, then to 255°C at a rate of 8°C / h, and then to 255°C at a rate of 5°C / h 330°C, keep warm for 5 hours, and carry out preheating treatment; the preheated isostatic pressed product is placed in the impregnation equipment, vacuumized, and then the impregnation equipment is injected with liquid asphalt at a temperature of 220°C to form an impregnation system, and the pressure applied to the impregnation system is 1.7-1.85Mpa, carry out impregnation treatment; after the applied pressure remains unchanged, cool the impregnation system to 55°C at a cooling rate of 55-65°C / h while maintaining the pressure: the cooled impregnation system Heating until the temperature of the asphalt in the impregnation system is above the softening point and the fluidity is good, and when the surface temperature of the product reaches the asphalt softening point of 90...

Embodiment 2

[0037] The isostatic graphite product is heated freely from room temperature to 180°C for 3 hours, then heated to 200°C at a rate of 15°C / h, then raised to 260°C at a rate of 9°C / h, and then heated to 320°C, keep warm for 4 hours, and carry out preheating treatment; the preheated isostatic pressed product is placed in the impregnation equipment, vacuumized, and then injected into the impregnation equipment with liquid asphalt at a temperature of 200°C to form an impregnation system, and the pressure applied to the impregnation system is 1.7-1.85Mpa, carry out impregnation treatment; after the applied pressure remains unchanged, cool the impregnation system to 60°C at a cooling rate of 55-65°C / h while maintaining the pressure: the cooled impregnation system Heating until the temperature of the asphalt in the impregnation system is above the softening point and the fluidity is good, and when the surface temperature of the product reaches the softening point of 85°C, stop heating....

Embodiment 3

[0039] The isostatic graphite product was heated freely from room temperature to 180°C for 4 hours, then raised to 205°C at a rate of 9°C / h, then to 255°C at a rate of 6°C / h, and then to 330°C, keep warm for 3 hours, and carry out preheating treatment; the preheated isostatic pressed product is placed in the impregnation equipment, vacuumized, and then the impregnation equipment is injected with liquid asphalt at a temperature of 190°C to form an impregnation system, and the pressure applied to the impregnation system is 1.7-1.85Mpa, carry out impregnation treatment; after the applied pressure remains unchanged, cool the impregnation system to 50°C at a cooling rate of 55-65°C / h while maintaining the pressure: the cooled impregnation system Heating until the temperature of the asphalt in the impregnation system is above the softening point and the fluidity is good, and when the surface temperature of the product reaches the softening point of 80°C, stop heating. At the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com