Heavy oil cracking catalyst and application thereof

A heavy oil cracking and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, cracking, etc., can solve the problems of poor anti-heavy metal pollution performance, insufficient total yield of gasoline, diesel and liquefied gas, and achieve anti-metal pollution Strong ability, strong anti-calcium and iron pollution ability, good coke selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

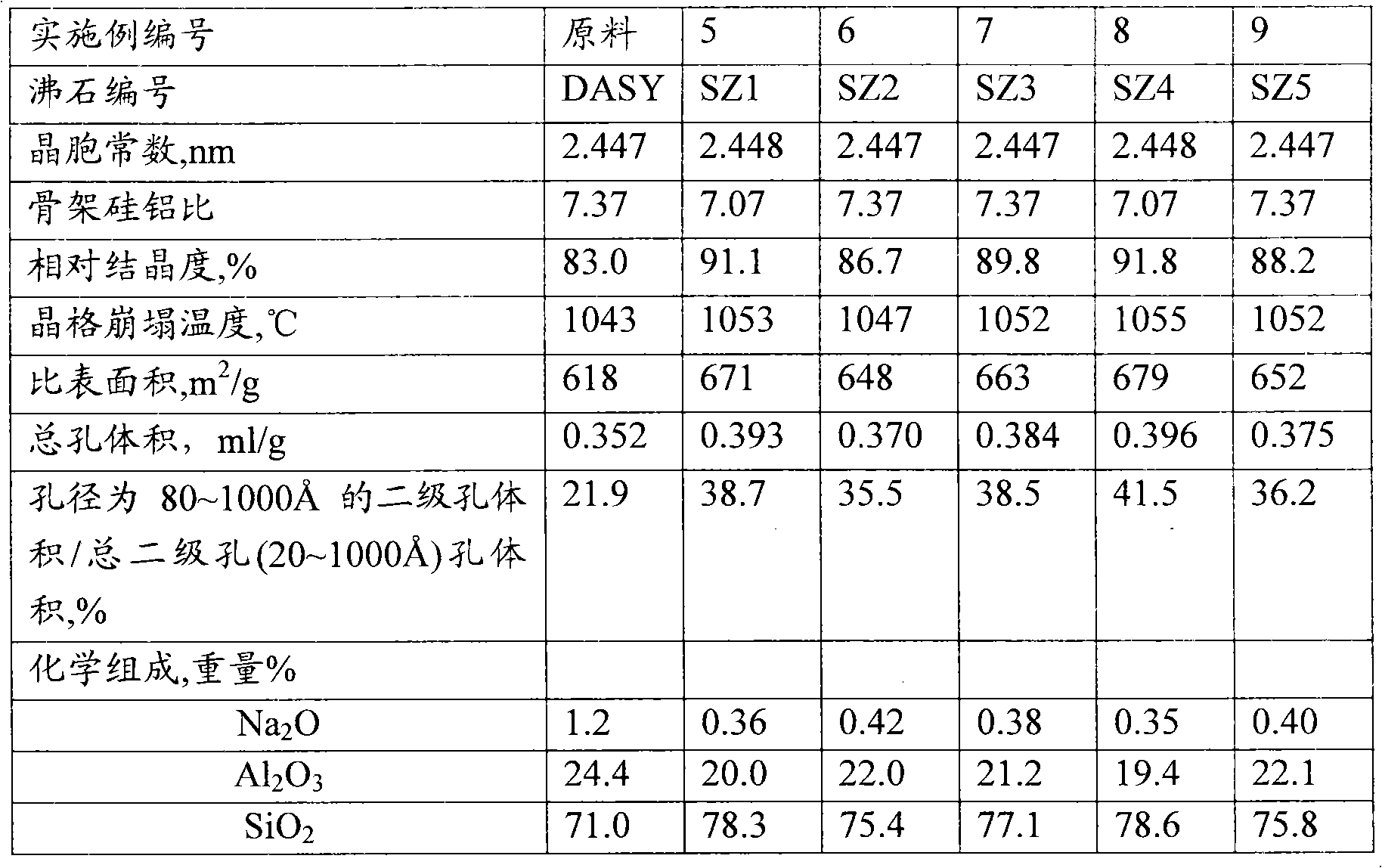

[0015] The preparation method of the modified ultra-stable Y-type zeolite comprises: mixing the hydrothermal ultra-stable Y-type zeolite prepared according to the prior art with a mixed acid solution with a concentration of 0.01-3N at a liquid-solid ratio of 20-40, Seal it, fill it with gas to make the pressure of the system 0.1-0.5MPa (gauge pressure), then keep it at 95-130°C and 0.1-0.5MPa (gauge pressure) for 5-60 minutes, then filter, wash and dry to obtain the obtained The modified ultra-stable Y-type zeolite described above; wherein, the mixed acid solution is a solution comprising an inorganic acid and an organic acid, and the ratio of the equivalent concentration of the organic acid and the inorganic acid in the solution is 2.5:1 to 1:2, preferably 2:1 to 1:1.5. The inorganic acid is one or more of sulfuric acid, hydrochloric acid, nitric acid, phosphoric acid, preferably hydrochloric acid; the organic acid is one or more of citric acid, oxalic acid, acetic acid, form...

Embodiment 1

[0029] Under stirring, in 16.7 kilograms of decationized water, add 11.3 kilograms of retort earth, after stirring for 15 minutes, add 179 grams of chemically pure hydrochloric acid (concentration is 36.5% by weight), stir for 30 minutes, add 456 grams of lanthanum chloride (LaCl 3 ·7H 2 O, produced by Beijing Chemical Reagent Company), after stirring for 60 minutes, a slurry with a solid content of 35% by weight was obtained, which was denoted as T1.

Embodiment 2

[0031] In 12.7 kg of decationized water, add 912 g of lanthanum chloride (same as above) and 200 g of titanium dioxide (produced by Beijing Chemical Reagent Company), after stirring for 10 minutes, add 10.9 kg of retort earth, stir for 30 minutes, then add 48 g of chemical Pure hydrochloric acid (concentration: 36.5% by weight) was stirred for 60 minutes to obtain a slurry with a solid content of 40% by weight, which was recorded as T2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com