Catalytic cracking catalyst and preparation method thereof

A catalytic cracking and catalyst technology, applied in the direction of catalyst activation/preparation, catalytic cracking, physical/chemical process catalysts, etc., can solve the problem of high coke formation of catalytic cracking catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

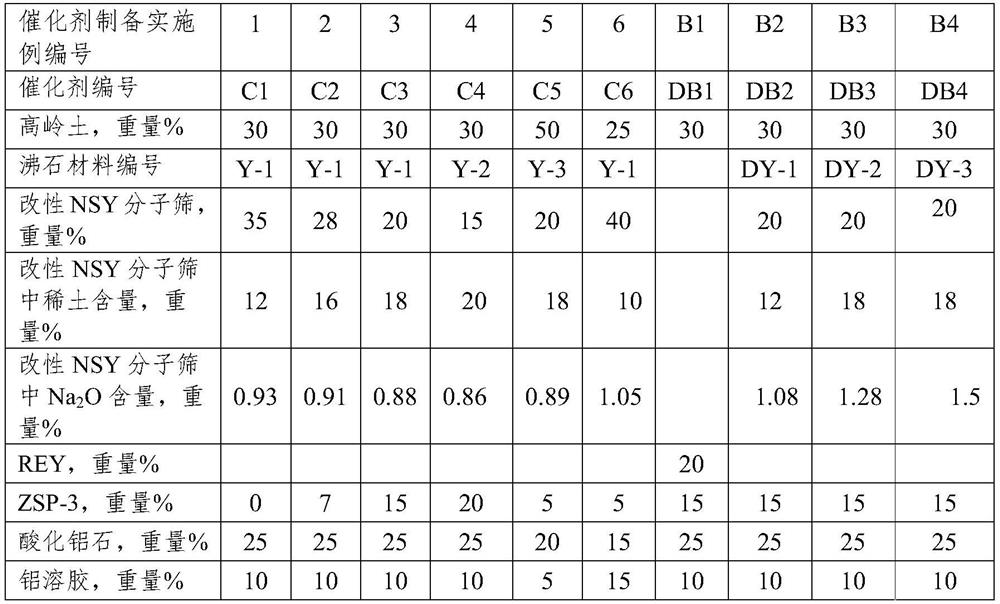

Examples

Embodiment approach

[0043] One embodiment, the modified NSY molecular sieve is prepared according to the following steps:

[0044] (1) converting kaolin into metakaolin by roasting and dehydrating at 500-900°C, pulverizing it to make a powder with a particle size of less than 10 microns;

[0045] (2) adding sodium silicate, directing agent, sodium hydroxide solution and water to metakaolin powder to make a reaction slurry, wherein the mass ratio of directing agent to metakaolin is 0.01 to 1.0;

[0046] (3) Crystallize the reaction slurry prepared in (2) at 88-98°C for 1-70 hours, such as 5-40 hours or 6-30 hours or 8-16 hours, and then supplement solid silica gel, wherein the mass ratio of solid silica gel to metakaolin 0.01~1.0;

[0047] (4) Crystallize the reaction raw material prepared in (3) under stirring at 88-98° C., the crystallization time is 1-20 hours, such as 8-20 hours or 12-16 hours, and then filter and dry to obtain the compound synthesized by in-situ crystallization NSY molecula...

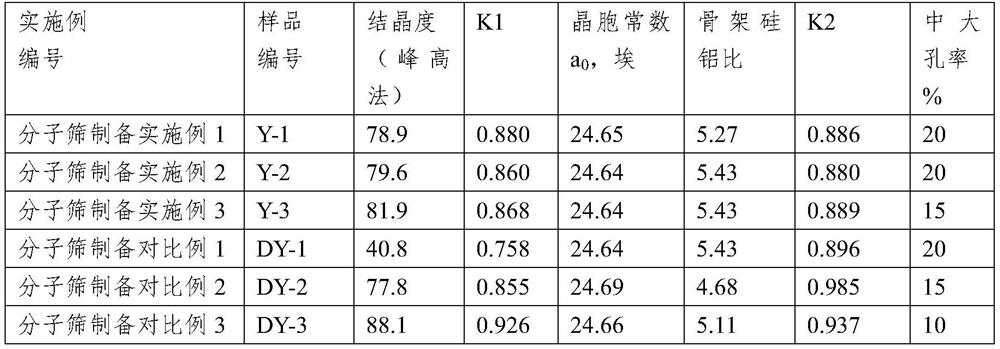

preparation Embodiment 1

[0063] 100 kilograms of pulverized metakaolin powders were added with 400 kilograms of sodium silicate solution (containing 20.05% by weight of SiO2) under stirring. 2 , 6.41 wt% Na 2 (0), 60 kilograms of directing agent and 100 kilograms of concentrations are 5% by weight of sodium hydroxide solution. Raise the temperature to 95°C and stir at a constant temperature. After 8 hours, add 10 kg of solid silica gel (Qingdao Ocean Chemical Group Special Silica Gel Factory, Type A), and recrystallize for 12 hours. The stirring speed is 400 rpm during addition and crystallization. After the crystallization was completed, the crystallization tank was rapidly cooled, filtered, and washed with water until the pH value of the washing solution was less than 10. Drying at 120° C. for 2 hours obtained the zeolite material Y-1. Measure Y-1 by X-ray diffraction method, crystallinity of peak height method, K1 value of ratio of crystallinity of peak height method to crystallinity of peak area ...

preparation Embodiment 2

[0065] Prepare the method for embodiment 1 by molecular sieve, the metakaolin powder after 100 kilograms of pulverizations, add 380 kilograms of sodium silicate solutions (containing the SiO of 20.05% by weight) under stirring 2 , 6.41 wt% Na 2 (0), 60 kilograms of directing agent, 100 kilograms of concentration is the sodium hydroxide solution of 5% by weight. Raise the temperature to 93°C and stir at a constant temperature. After 8 hours, add 15 kg of solid silica gel (Qingdao Ocean Chemical Group Special Silica Gel Factory, Type A), and recrystallize for 14 hours. The stirring speed is 400 rpm during addition and crystallization. After the crystallization is completed, the crystallization tank is rapidly cooled, filtered, and washed with water until the pH value of the washing liquid is less than 10. Drying at 120° C. for 2 hours yields the zeolite material Y-2. Measure Y-2 by X-ray diffraction method, crystallinity of peak height method, K1 value of the ratio of crystalli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com