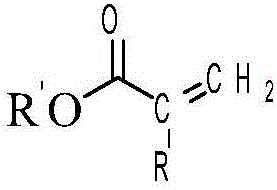

Method for synthesis of (meth)acrylate diluent

A technology of acrylates and alkyl acrylates, which is applied in the field of transesterification synthesis, can solve the problems of easy deactivation of organic titanium catalysts, high consumption of raw materials and energy consumption, low selectivity of alkaline activity, etc., and achieve stable and easy production of products. Effects of separation, improved processing capacity, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

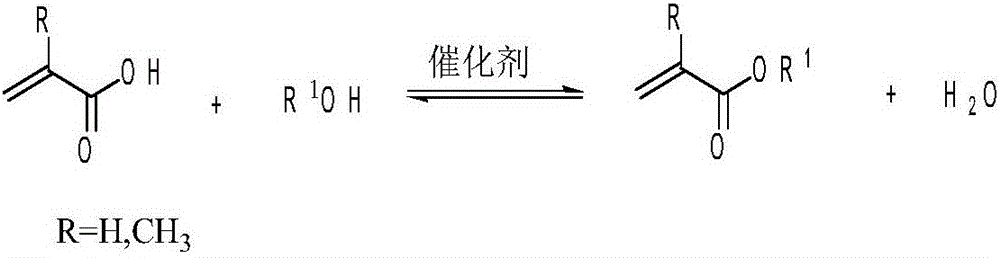

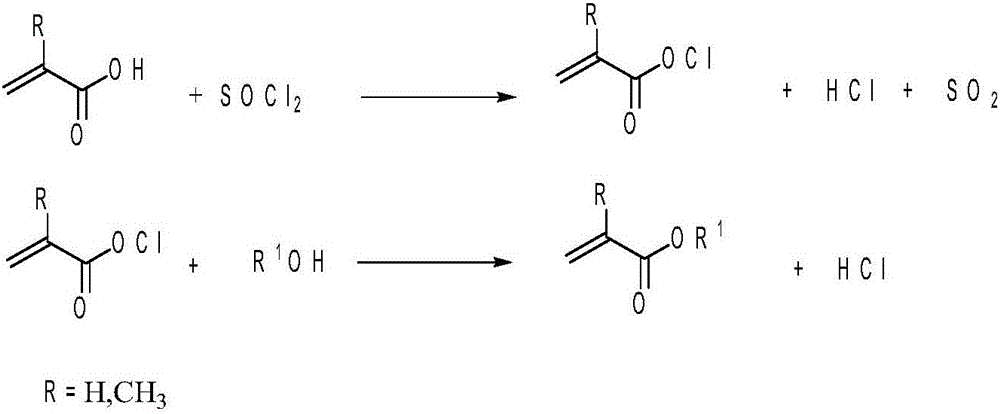

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 Preparation of diethylene glycol di(meth)acrylate

[0041] A mixture of the following components was added to a 29 cm diameter copper wire mesh packed column with a temperature display / controller, magnetic stirrer, dry air inlet, distillation head, distillate ratio-removal vapor pressure thermostat and In the 100ml four-neck flask of the distillate receiver gradually: 5.31g (0.05mol) diethylene glycol (DEG), 25.83g (0.3mol) methyl acrylate (MA), 0.03g (0.0002mol) p-hydroxybenzene Methyl ether and, 0.11g (0.0002mol) dibutyltin dilaurate. The mixture was then warmed to reflux. During the reaction process, a certain amount of air was introduced, and the reflux was continuously heated under normal pressure, and the reaction azeotropic mixture MA-methanol was removed at the same time. After the reaction reaches the end point, cool the reaction solution to 50°C, add 0.10g of neutral activated carbon, and continue to keep warm and stir for 0.5-1 hour. Diacrylat...

Embodiment 2

[0042] Embodiment 2 Preparation of ethylene glycol di(meth)acrylate

[0043] A mixture of the following components was added to a 29 cm diameter copper wire mesh packed column with a temperature display / controller, magnetic stirrer, dry air inlet, distillation head, distillate ratio-removal vapor pressure thermostat and In the 100ml four-neck flask of the distillate receiver gradually: 3.1g (0.05mol) ethylene glycol, 25.83g (0.3mol) methyl acrylate (MA), 0.03g (0.0002mol) p-hydroxyanisole and 0.11g ( 0.0002mol) dibutyltin dilaurate. The mixture was then warmed to reflux. During the reaction process, a certain amount of air was introduced, and the reflux was continuously heated under normal pressure, and the reaction azeotropic mixture MA-methanol was removed at the same time. After the reaction reaches the end point, cool the reaction liquid to 50°C, add 0.10g of neutral activated carbon, and continue to heat and stir for 0.5-1 hour. After the end, the reaction liquid is fil...

Embodiment 3

[0044] Embodiment 3 Preparation of trimethylolpropane tri(meth)acrylate

[0045] A mixture of the following components was added to a 29 cm diameter copper wire mesh packed column with temperature display / controller, magnetic stirrer, dry air inlet, distillation head, distillate ratio-removal vapor pressure temperature control In the 250ml four-neck flask of the receiver and the step-by-step distillate receiver: 13.42g (0.5mol) trimethylolpropane (TMP), 77.5g (0.9mol) MA, 0.07g (0.0006mol) MEHQ, 0.50g (0.004mol) ) anhydrous potassium carbonate, feed into air and heat up to the reflux of the reaction solution, stabilize the reaction to the end of the reaction. Post-processing: Cool the reaction liquid to 50°C, add 0.10g of neutral activated carbon, and continue to heat and stir for 1 hour. After the end, the reaction liquid is vacuum filtered, and the filtrate is rotary evaporated under reduced pressure. The highest were 77.1% and 90.1% respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com