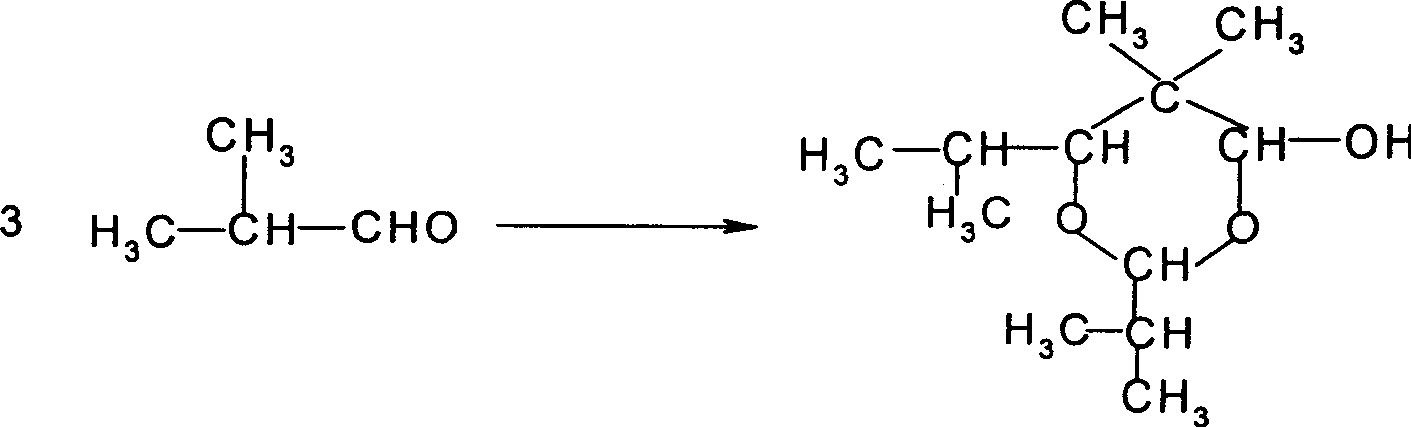

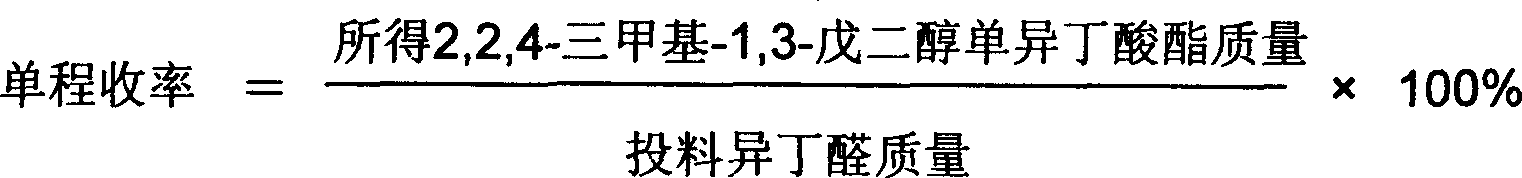

Production of 2,2,4-trimethyl-1,-3-pentadiol mono-isobutyric acid

A technology of pentanediol monoisobutyrate and trimethyl, applied in the field of organic chemical synthesis, can solve the problems of low cost, insufficient output, high single-pass yield, and achieve mild reaction conditions, less equipment corrosion, and single-pass yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1 Low-temperature condensation pretreatment of isobutyraldehyde

[0024] In a 100ml three-necked flask equipped with a thermometer, a reflux condenser and a constant pressure dropping funnel, add 5g of 5% sodium hydroxide solution, stir magnetically, and under nitrogen protection, normal pressure, and 20°C, within 1h Continuously and slowly add 15 g of isobutyraldehyde dropwise, and continue to react at 35° C. for 4 h after the dropwise addition; stop the reaction, wash with water, stand to separate layers, the lower layer is a water layer, and the upper layer is an oil layer.

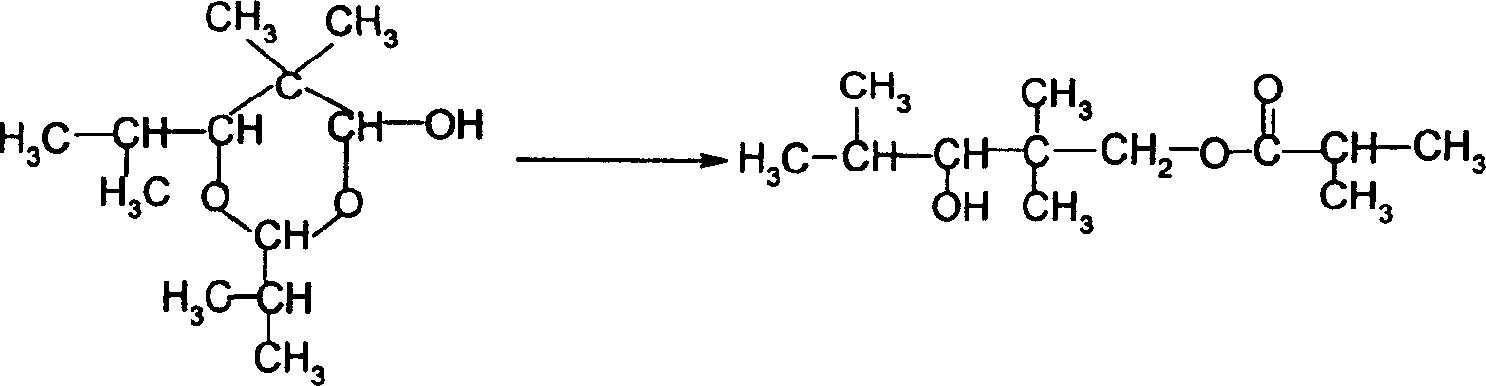

[0025] Step 2 Intramolecular Cannizzaro Reaction

[0026] Add the oil layer obtained by the low-temperature condensation pretreatment of isobutyraldehyde into a 100mL three-necked flask equipped with a thermometer and a reflux condenser, add 0.2g of magnesium aluminum hydrotalcite, stir magnetically, and react under nitrogen protection, normal pressure, and 60°C 1h, then heat up to 60-65°C...

Embodiment 2-4

[0033] Example

Embodiment 5-7

[0035] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com