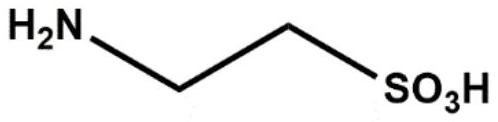

Method for preparing taurine from sodium isethionate

A technology of sodium isethionate and taurine, applied in the preparation of sulfonic acid, preparation of sulfonate, chemical instruments and methods, etc., can solve the problem of harsh reaction conditions, unmentioned single-pass yield, and side effects of ammonolysis reaction. There are many problems such as many products, and the effects of mild process conditions, promotion of electron transfer and high conversion rate are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Preparation of Pd-C / Al2O3 type-selective catalyst:

[0053] Add 3.0g (1.0wt%) sodium taurate to 300g ethanol aqueous solution (68.0wt%), then add 80.3g aluminum sec-butoxide, after stirring at 25 ℃, add 3.76g palladium nitrate, maintain temperature and continue Stir, then carry out the hydrolysis reaction at 32°C for 5h; then filter the precipitate, wash with water, dry at 100°C for 4h, and then put it in a nitrogen roaster at 450°C for 7h under normal pressure to obtain Pd-C / Al 2 o 3 type-selective catalyst.

[0054] Preparation of taurine from sodium isethionate:

[0055] 600g of sodium isethionate solution (23.0wt%) was placed in a 1L high-pressure reactor, and liquid ammonia was introduced to control the ammonia concentration to be 21.0wt%, and then 2.07g (1.5wt%) of the above-mentioned Pd-C / al 2 o 3 Type-selective catalyst, the reaction system is heated up to 140 ° C, the system pressure is 8.0 MPa gauge pressure, ammonolysis reaction is carried out, the reac...

Embodiment 2

[0058] Add 2.1g (0.7wt%) sodium taurate to 300g ethanol aqueous solution (55.0wt%), then add 49.2g aluminum tert-butoxide, after stirring at 25 ℃, add 1.35g palladium acetate, maintain temperature and continue Stir, then carry out the hydrolysis reaction at 20°C for 3h, filter the precipitate, wash, dry at 120°C for 3h, and then place it in a nitrogen roasting furnace at 380°C for 5h to obtain Pd-C / Al 2 o 3 type-selective catalyst.

[0059] 600g of sodium isethionate solution (18.0wt%) was placed in a 1L high-pressure reactor, and a certain amount of liquid ammonia was introduced to control the ammonia concentration to be 22.0wt%, and then 1.08g (1.0wt%) of the above-mentioned Pd- C / Al 2 o 3 type-selective catalyst, the reaction system is heated up to 180°C, the system pressure is 9.0MPa, and the reaction is 70min. The conversion rate of ammonolysis reaction sodium isethionate is 98.9%, and the yield of sodium taurate obtained is 94.8%. The selectivities of sodium sulfonat...

Embodiment 3

[0062] Add 0.6g (0.2wt%) sodium taurate to 300g ethanol aqueous solution (30.0wt%), then add 8.33g aluminum isopropoxide, after stirring at 25 ℃, add 0.07g palladium chloride, maintain temperature Continue to stir, then carry out the hydrolysis reaction at 45°C for 1h, filter the precipitate, wash, dry at 80°C for 2h, and then place it in a nitrogen roaster at 400°C for 6h to obtain Pd-C / Al 2 o 3 type-selective catalyst.

[0063] 600g of sodium isethionate solution (15.0wt%) was placed in a 1L high-pressure reactor, and a certain amount of liquid ammonia was introduced to control the ammonia concentration to be 20.0wt%, and then 0.45g (0.5wt%) of the above-mentioned Pd- C / Al 2 o 3 Type-selective catalyst, the reaction system is heated up to 150 ° C, the system pressure is 8.5 MPa, and the reaction is 35 minutes. The conversion rate of ammonolysis reaction sodium isethionate is 99.1%, and the yield of sodium taurate obtained is 95.8%. The selectivities of sodium sulfonate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com