Method for catalytic conversion of methanol and naphtha into light olefins

A low-carbon olefin and catalytic conversion technology, which is applied in catalytic cracking, petroleum industry, hydrocarbon cracking and hydrocarbon production, etc., can solve the problem of low olefin yield, improve single-pass yield, increase yield, and ensure gas-solid contact time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

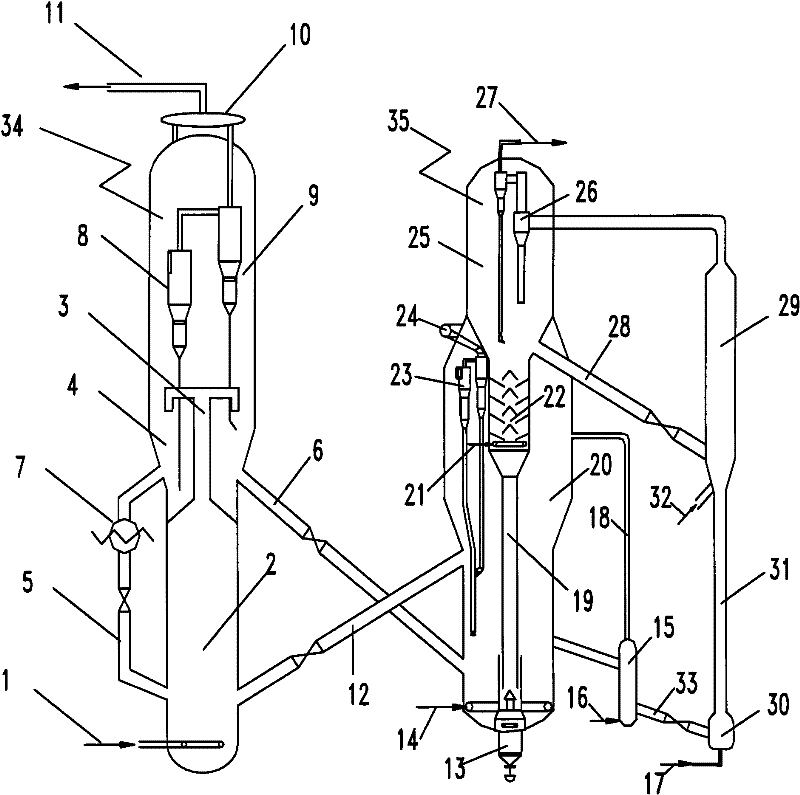

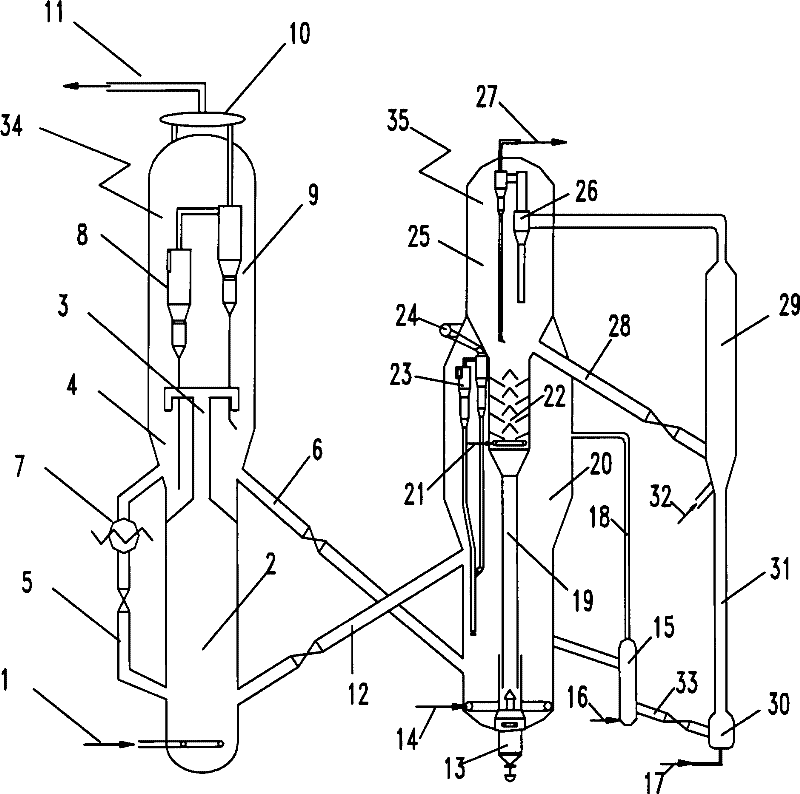

[0019] in such as figure 1 In the shown reaction-regeneration device, the catalyst is ZSM-5, and the silicon-aluminum ratio is 50 (volume). The methanol conversion reactor is a fast fluidized bed, the average temperature of the reaction zone of the methanol conversion reactor is 440°C, the gas phase velocity is 1.12 m / s, the methanol feed is 99.5% pure, and the methanol weight hourly space velocity is 5.7 hours -1 , the ratio of the mass flow rate of the regenerated inclined tube catalyst to the mass flow rate of the methanol feed is 0.7, the average temperature of the regenerator is 675° C., the carbon deposition amount of the spent agent is 2.7% (weight), and the carbon deposition amount of the regenerated catalyst is 0.29% (weight). . The auxiliary settling stripper is located on the upper part of the regenerator, and the stripping zone is built in the regenerator. The naphtha conversion reactor is a variable-diameter riser, one riser, the ratio of the diameter of the upp...

Embodiment 2~3

[0021] According to the conditions described in Example 1, only the temperature in the reaction zone of the methanol conversion reactor was changed. The experimental results are shown in Table 1.

[0022] Table 1

[0023]

Embodiment 4~5

[0025] According to the conditions described in Example 1, only the gas phase velocity in the reaction zone of the methanol conversion reactor was changed. The experimental results are shown in Table 2.

[0026] Table 2

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com