Reactor, system and method for producing tripolycyanamide

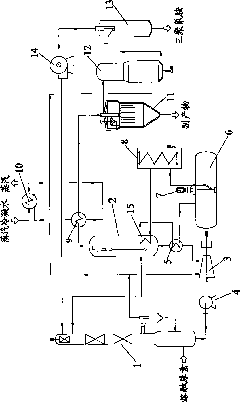

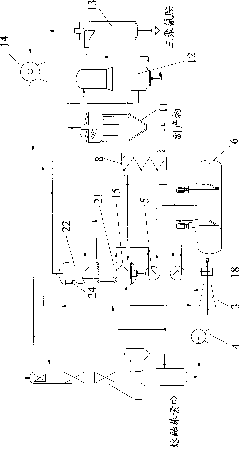

A melamine and reactor technology, applied in the field of melamine preparation in a multi-layer fluidized bed, can solve the problems of low urea conversion rate by-products, etc., achieve the effects of reducing energy consumption, increasing single-pass yield, and reducing process load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

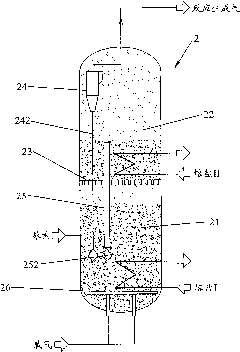

[0030] figure 2 A specific example of a reactor according to the invention is shown. In the figure, the reactor 2 is a vertical cylinder, which is divided into a lower reaction section 21 and an upper cooling section 22 by a cooling section gas distributor 23 . One or more cyclones 24 are arranged in the cooling section 22 , the discharge legs 242 of which extend to the reaction section 21 . Preferably, it extends into the dense phase region of the reaction section. An overflow pipe 25 is also provided in the reactor 2 for balancing the materials in the reaction section 21 and the cooling section 22 . In the state of use, the upper port of the overflow pipe 25 is located at the junction of the dense-phase area and the dilute-phase area of the cooling section, and the lower end is located at the dense-phase area of the reaction section. Preferably, a double-cone member 252 is provided at the lower end of the overflow pipe to prevent gas short circuit. The gas distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com