Device and process for preparing high-concentration methylal

A methylal, high-concentration technology, applied in the field of high-concentration methylal preparation equipment, can solve the problems of large equipment investment, low single-pass yield, high energy consumption for separation, reduce energy consumption and equipment investment, and improve single-pass High yield and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

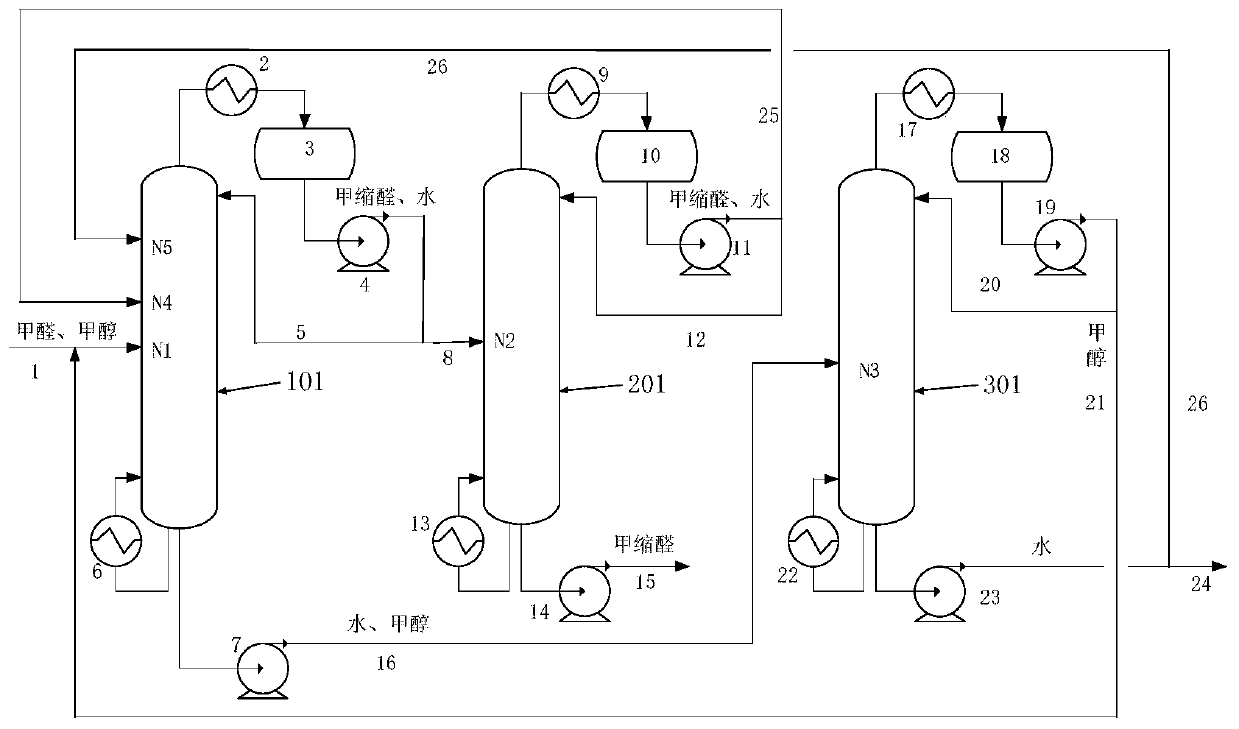

[0048] combine figure 1 The formaldehyde solution containing 37% formaldehyde mass fraction, the fresh methanol with a mass fraction of 99.9%, and the recycled methanol recovered from the top of the rectification tower 301 are mixed and then enter the first rectification tower 101 from the first feed port N1, wherein the formaldehyde solution The mass flow rate is 2000kg / h, the mass flow rate of fresh methanol is 1581.9kg / h, and the mass flow rate of methanol recovered from the top of the third distillation column 301 is 418.1kg / h. In steady state, 430 kg / h of the top discharge of the second rectifying tower 201 enters the first rectifying tower 101 from the fourth feed port N4, wherein the mass fractions of methylal, water and methanol are 93.13%, 4.31% and 2.56% respectively. %. The circulating extractant water from the bottom of the third rectification tower 301 enters the first rectification tower 101 through the fifth feed port N5 at a rate of 1000 kg / h.

[0049] The fi...

Embodiment 2

[0063] combine figure 1 , the formaldehyde aqueous solution containing formaldehyde mass fraction 45%, the fresh methanol of 99.9% mass fraction and the circulating methanol recovered from the top of the third rectification tower 301 are mixed and enter the first rectification tower 101 from the first feed port N1, wherein The mass flow rate of formaldehyde aqueous solution is 2600kg / h, the mass flow rate of fresh methanol is 2501.9kg / h, and the mass flow rate of methanol recovered from the top of the third distillation column 301 is 998.1kg / h. In the steady state, the second rectifying tower 201 top discharge 601.9kg / h enters the first rectifying tower 101 from the fourth feed port N4, wherein the mass fractions of methylal, water and methanol are respectively 92.66%, 5.07% and 2.27%. The circulating extractant water from the bottom of the third rectification tower 301 enters the first rectification tower 101 through the fifth feed port N5 at a rate of 1800 kg / h.

[0064] A...

Embodiment 3

[0077] combine figure 1 The dilute formaldehyde aqueous solution containing 22% formaldehyde mass fraction, the fresh methanol with a mass fraction of 99.9%, and the recycled methanol recovered from the top of the third rectification tower 301 are mixed and then enter the first rectification tower 101 through the first feed inlet N1, Among them, the mass flow rate of formaldehyde aqueous solution is 6000kg / h, the mass flow rate of fresh methanol is 2821.5kg / h, and the mass flow rate of methanol recovered from the top of the third rectifying tower 301 is 678.5kg / h. During the steady state, the second rectifying tower 201 overhead discharge 1346.3kg / h enters the first rectifying tower 101 from the fourth feed port N4, wherein the mass fractions of methylal, water and methanol are respectively 95.93%, 2.73% and 1.34%. The circulating extractant water from the bottom of the third rectification tower 301 enters the first rectification tower 101 through the fifth feed port N5 at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com