Method for preparing water solutable fertilizer containing humic acid

A water-soluble fertilizer, humic acid technology, applied in the direction of organic fertilizers, etc., can solve problems such as waste, clogged nozzles of sprayers, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

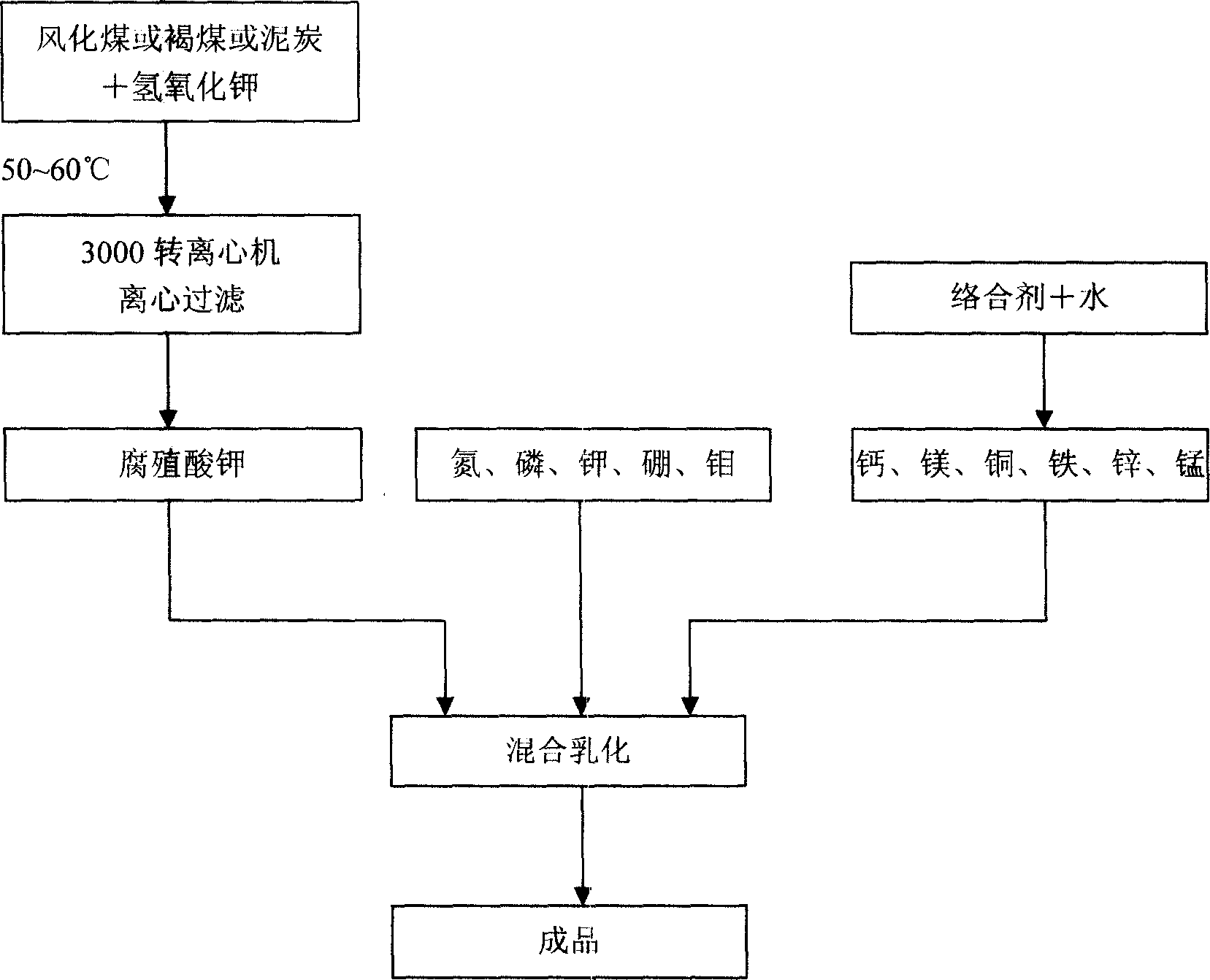

Method used

Image

Examples

Embodiment 1

[0031] Take 70kg of weathered coal containing more than 50% humic acid, add 480kg of water and 12kg of 90% potassium hydroxide, react for 3 hours at a temperature of 50-60 degrees, and centrifugally filter on a centrifuge at 3000 rpm to extract humic acid Potassium 500kg; add 130kg of urea, 140kg of potassium dihydrogen phosphate, 5kg of boric acid, 1kg of ammonium molybdate; then dissolve 13kg of complexing agent ethylenediaminetetraacetic acid with 151kg of water, then add 7kg of ferrous sulfate, 5kg of copper sulfate, 4kg of Zinc sulfate, 20kg magnesium sulfate, 20kg calcium nitrate, 4kg manganese sulfate, heated to dissolve. All the materials were mixed and then emulsified, and the finished product was obtained after emulsifying for 4 hours.

Embodiment 2

[0033] Take 70kg of peat containing more than 60% humic acid, add 330kg of water and 13kg of 90% potassium hydroxide, react for 4 hours at a temperature of 50-60 degrees, and centrifugally filter on a centrifuge at 3000 rpm to extract potassium humate 320kg; add 80kg of dissolved urea, 50kg of potassium dihydrogen phosphate, 12kg of boric acid, and 2kg of ammonium molybdate; add 25kg of complexing agent ethylenediaminetetraacetic acid and 250kg of water to dissolve, then add 110kg of ferrous sulfate and 42kg of copper sulfate , 32kg zinc sulfate, 30kg magnesium sulfate, 30kg calcium nitrate, 17kg manganese sulfate, heated and dissolved. All the materials were mixed and then emulsified, and the finished product was obtained after emulsifying for 4 hours.

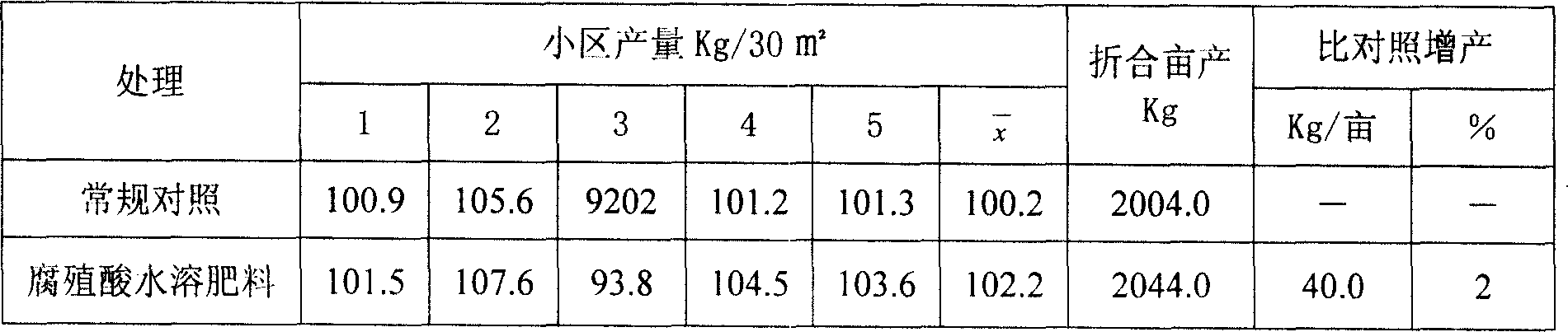

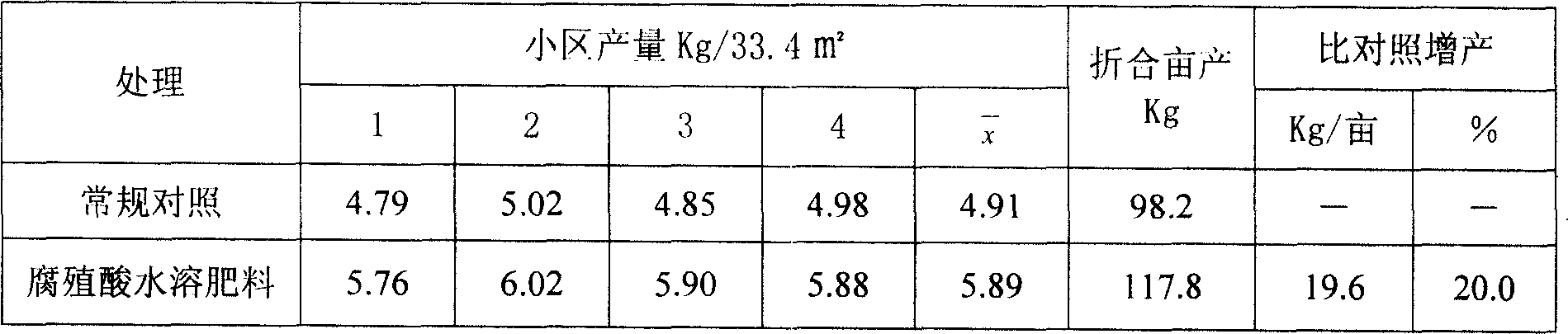

[0034] The effect of fertilizer of the present invention

[0035] 1. The mechanism of action of humic acid-containing water-soluble fertilizer:

[0036] Humic acid is mainly composed of humic acid and fulvic acid. The stud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com