Patents

Literature

67results about How to "Mix thoroughly mix well" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Long-acting flame retarding coating fabric with safety protection performance, and preparation process thereof

ActiveCN102615901AHigh strengthImprove uniformityFibre treatmentSynthetic resin layered productsSlurryMoisture permeation

The present invention discloses a long-acting flame retarding coating fabric with safety protection performance, and a preparation process thereof. According to the fabric, a first prime coat and a second prime coat are provided; a surface coating comprises a polyurethane resin, bromoethane, antimony oxide, and zinc borate; and a lining woven from a flame retarding polyacrylonitrile fiber silk is adhered to the other side of a coating layer, wherein the flame retarding polyacrylonitrile fiber silk comprises polyacrylonitrile fiber, cotton and aramid fiber, and a ratio of the polyacrylonitrile fiber to the cotton to the aramid fiber is 4:3.5-4.5:0.9-1.1. The preparation method comprises: respectively soaking and dissolving bromoethane, antimony oxide and zinc borate powder in toluene for at least 24 hours; uniformly mixing the bromoethane, the antimony oxide, the zinc borate powder and a hydrophilic polyurethane moisture permeation primer according to a mass ratio of 40:22-18:4-6:95-105 to form a prime coat slurry; mixing polyacrylonitrile fiber, cotton and aramid fiber according to a mass ratio of 4:3.5-4.5:0.9-1.1, silking to form the flame retarding polyacrylonitrile fiber silk, and adopting a flame retarding lining woven from the flame retarding polyacrylonitrile fiber silk, and adhering on the other side of the surface coating; and uniformly mixing a white slurry and a surface coating slurry to form a blended surface coating slurry. With the fabric of the present invention, the flame retarding time is long, the amount of the smoke generation is small, the droplet is not easily generated, the flame retarding effect is resistant to washing, and the hydrolysis of the flame retarding substances is avoided.

Owner:KUNSHAN HUAYANG NEW MATERIAL

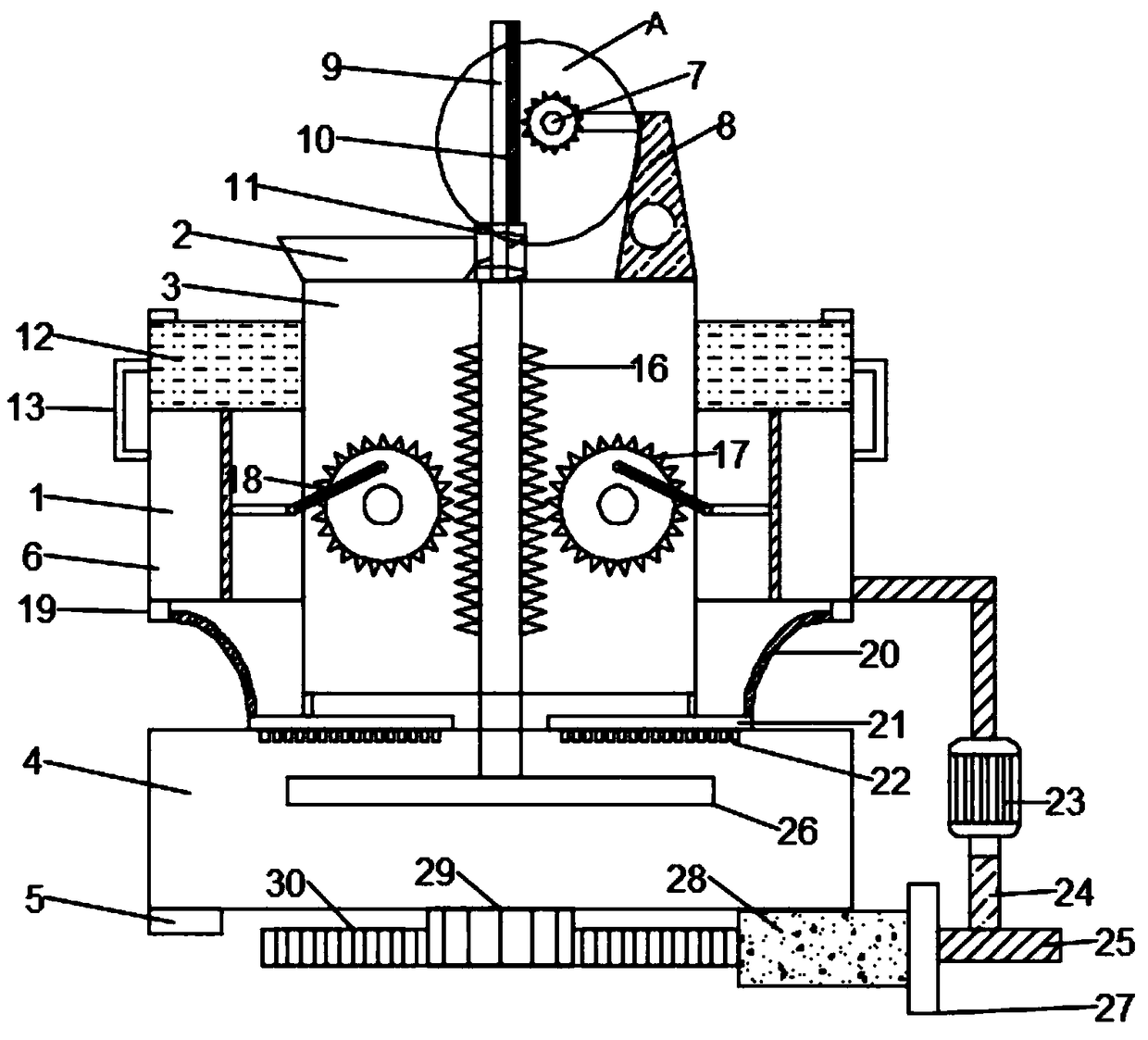

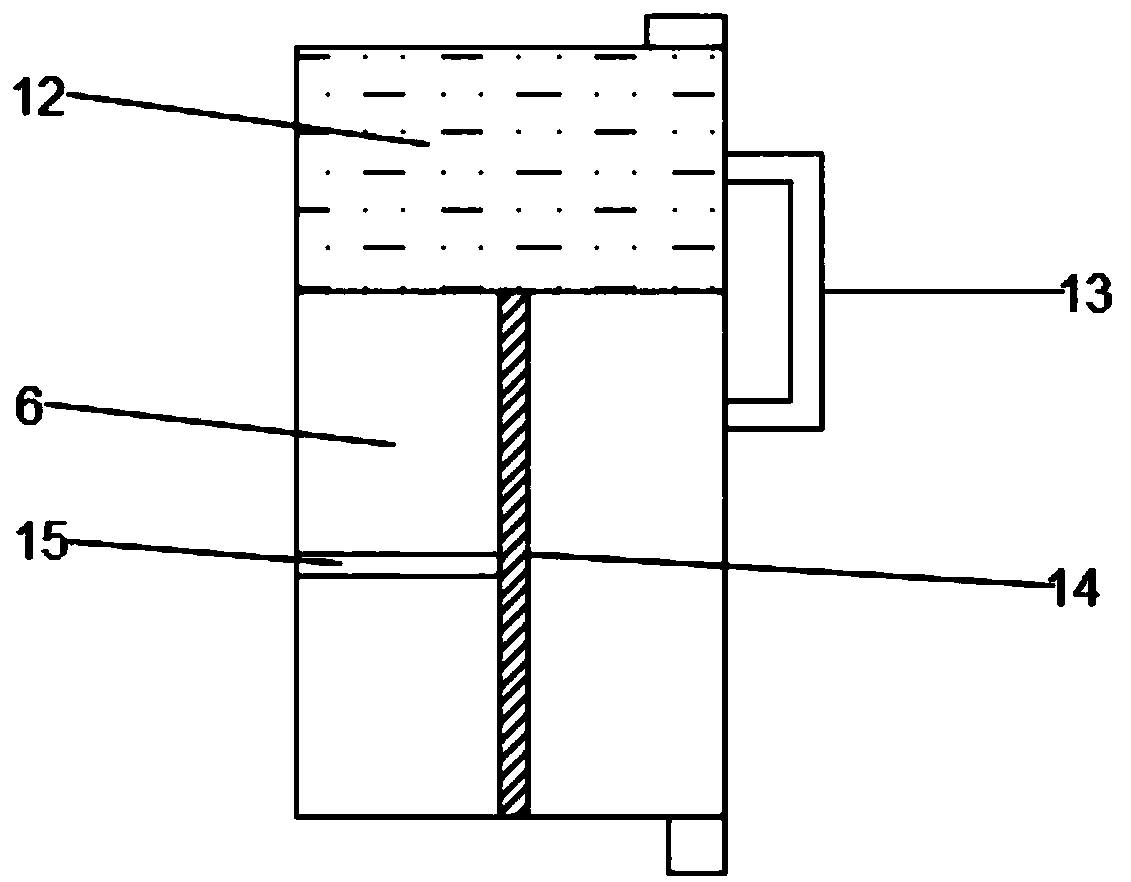

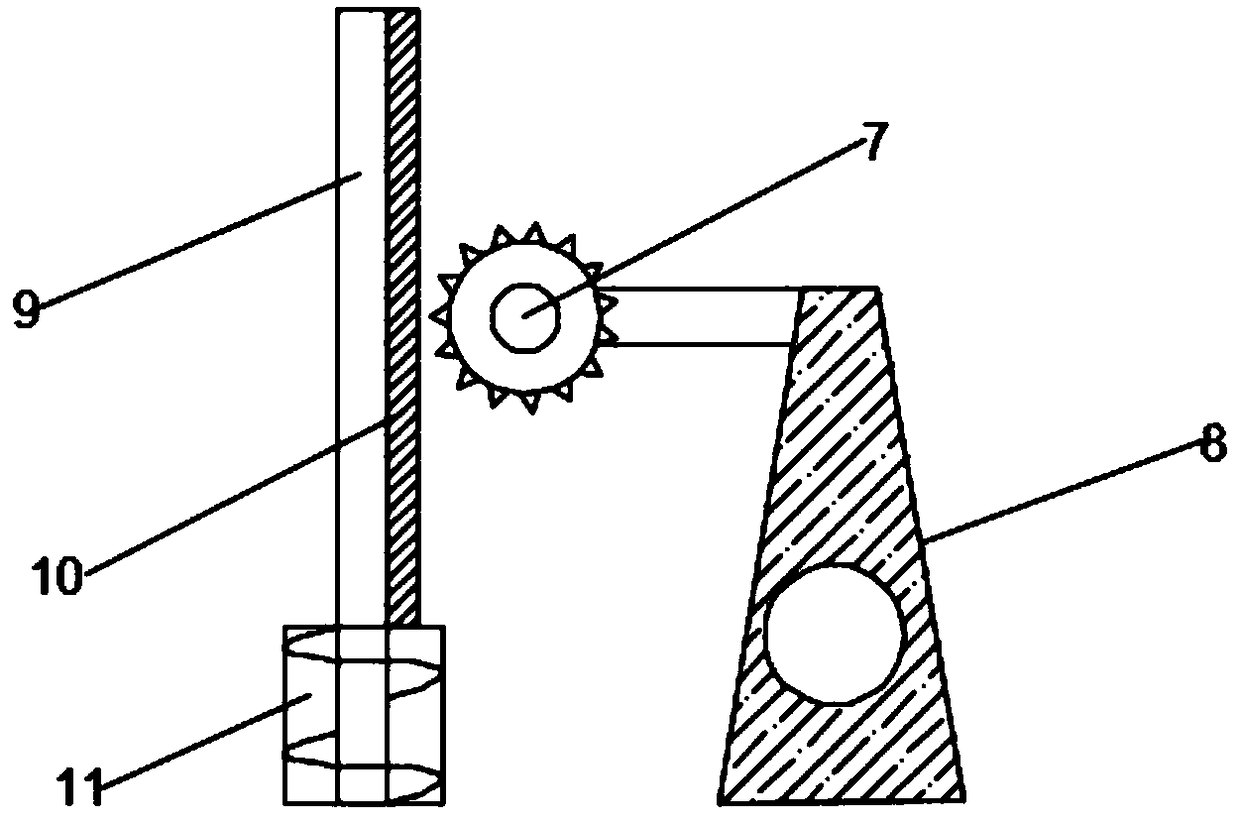

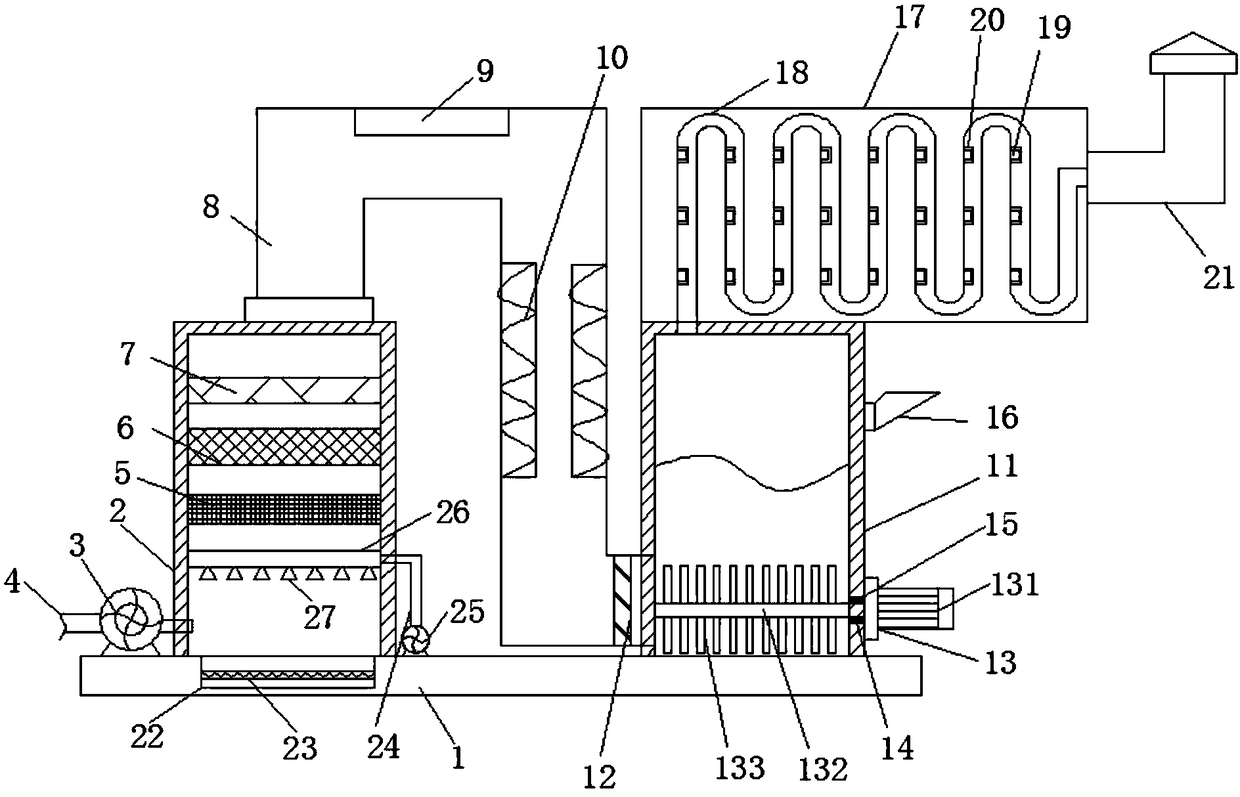

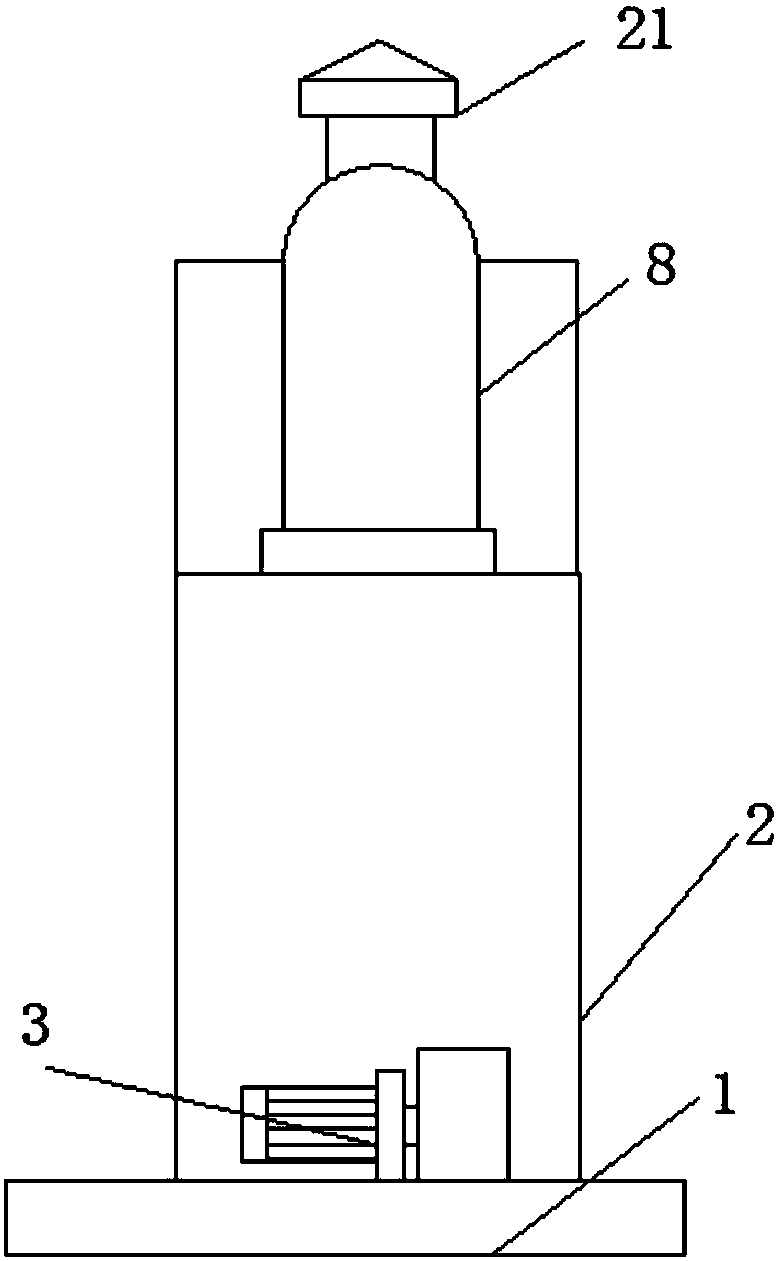

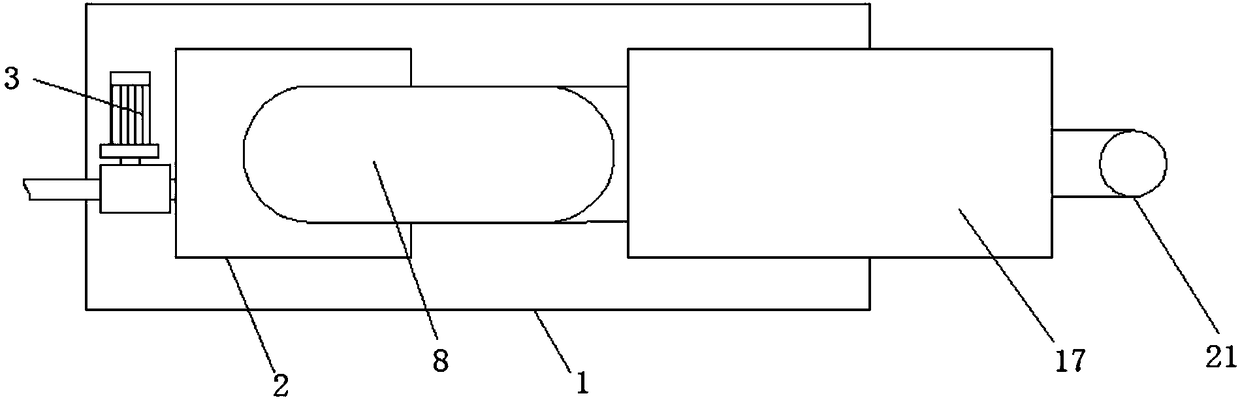

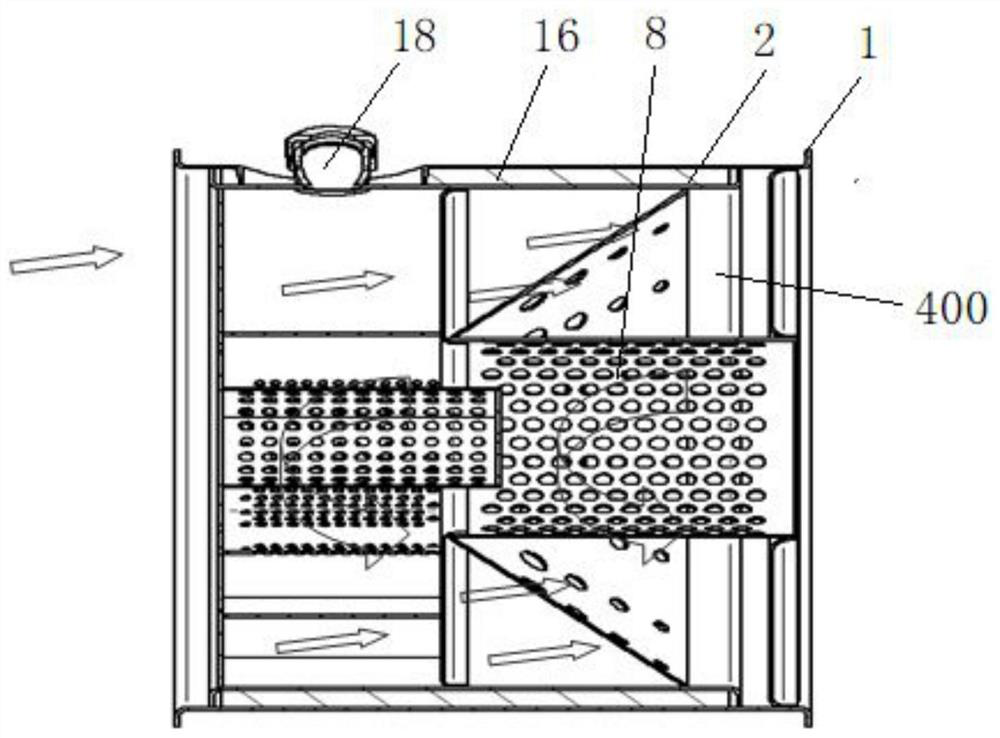

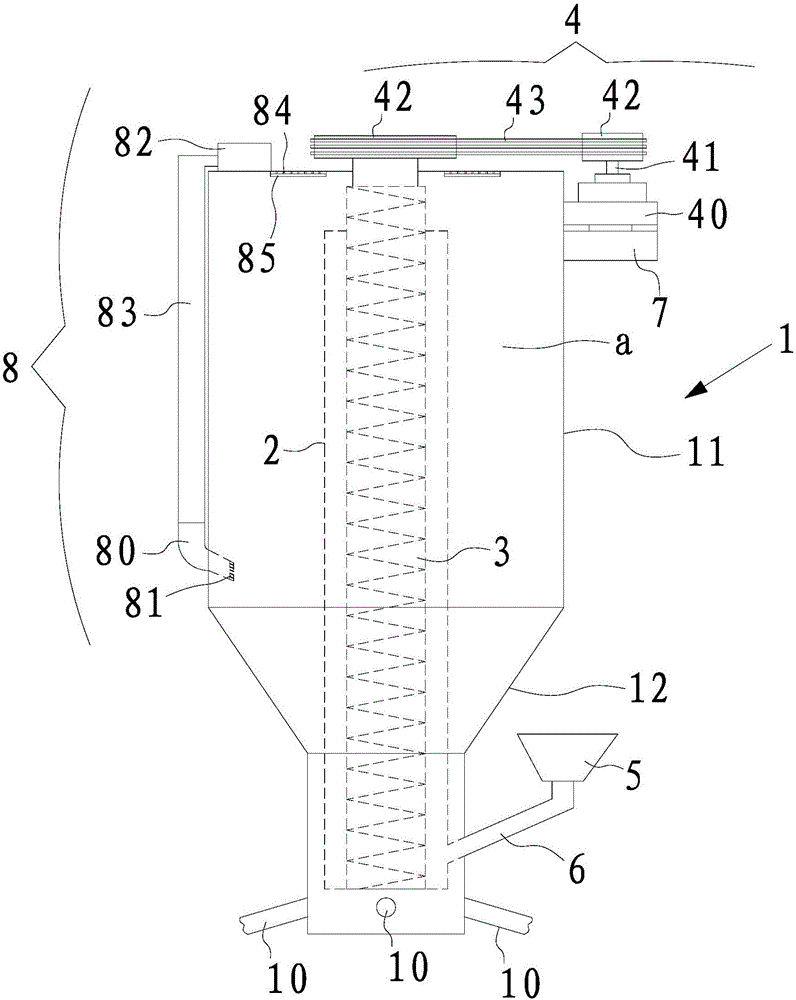

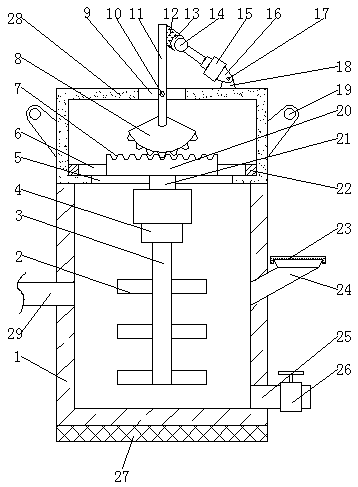

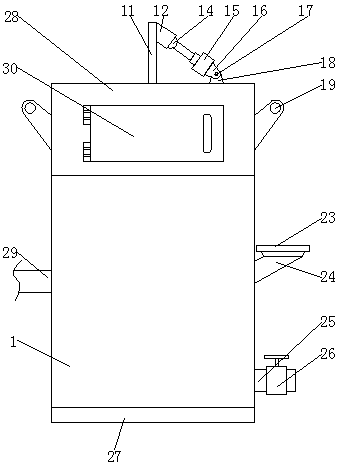

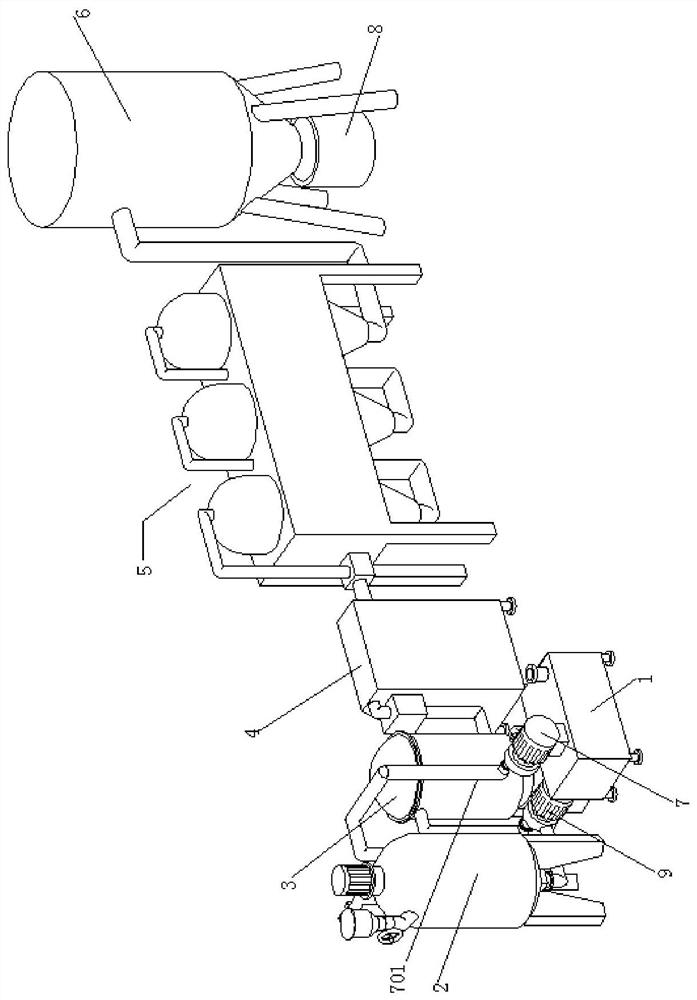

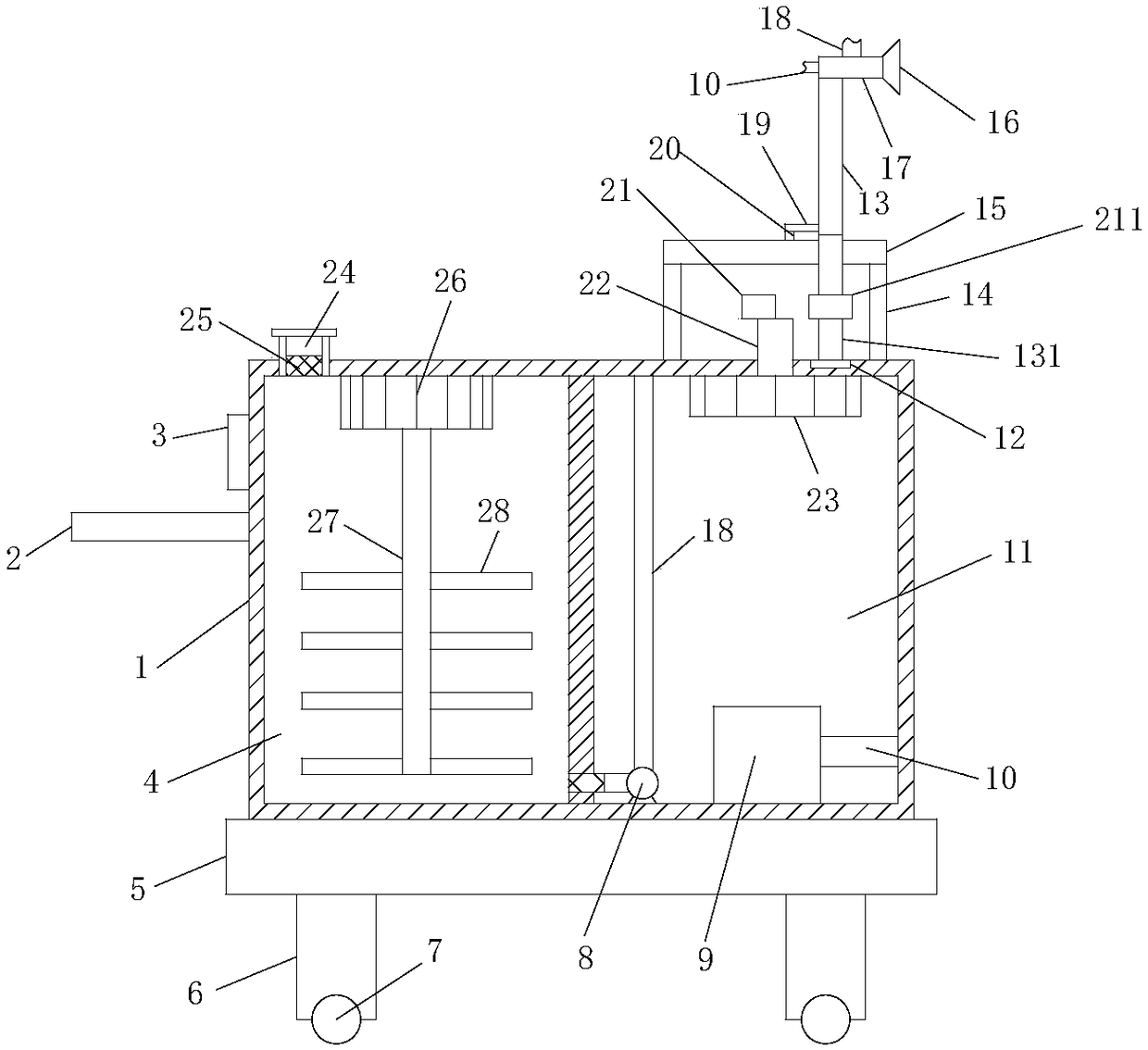

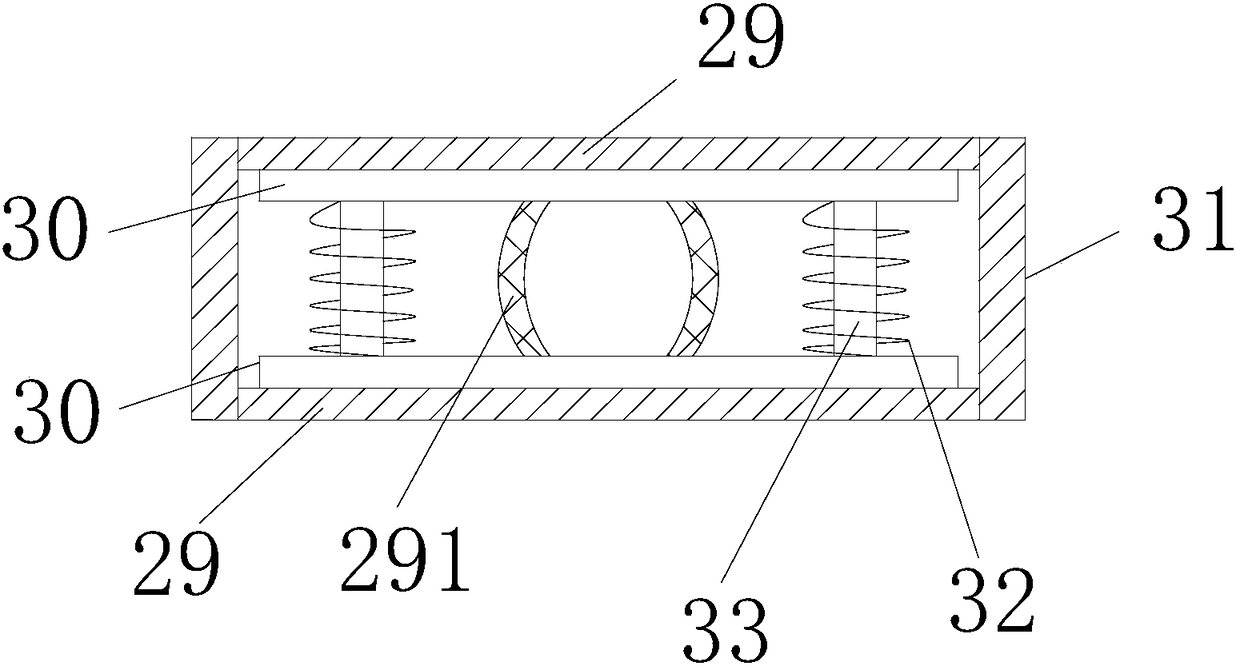

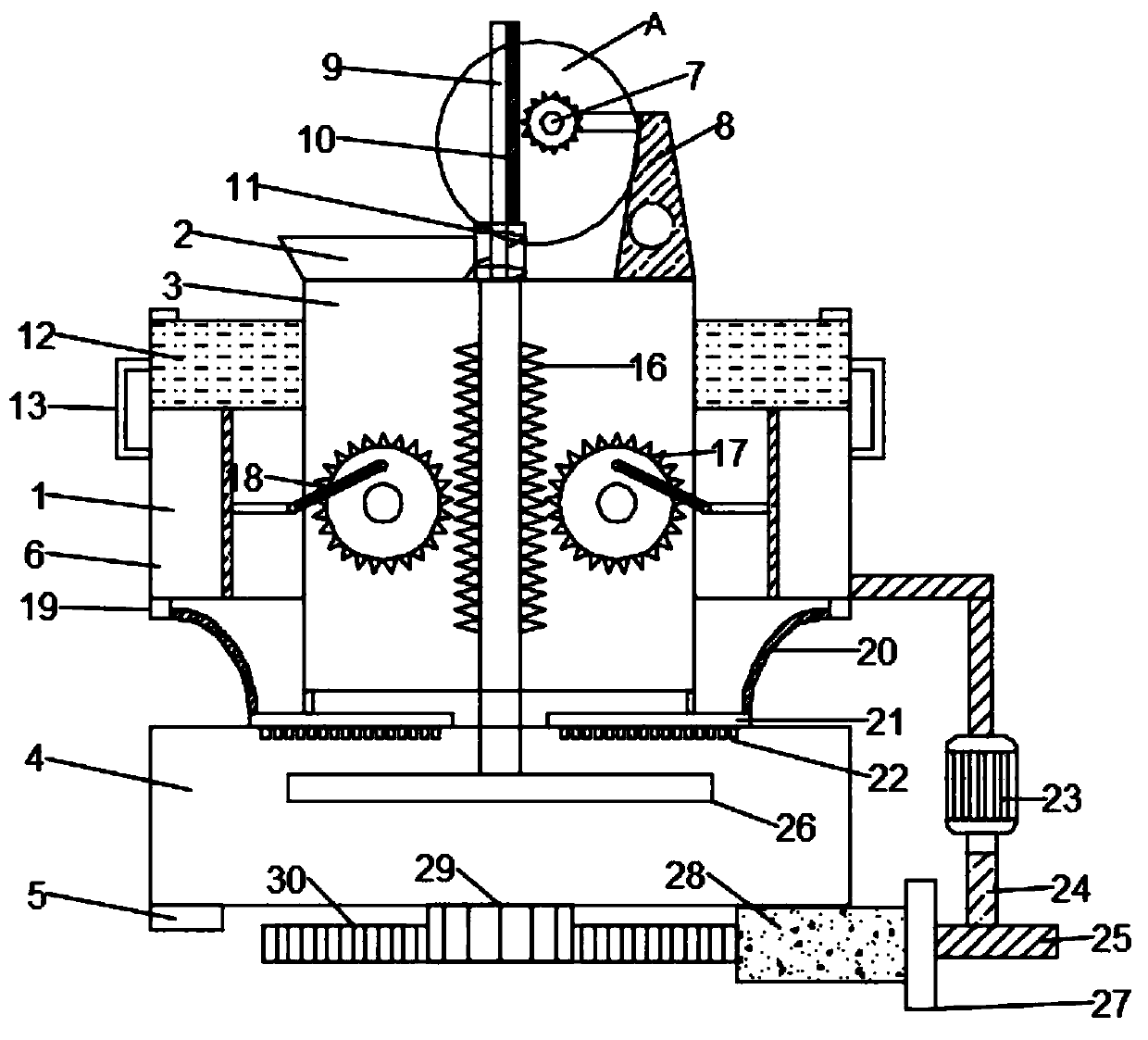

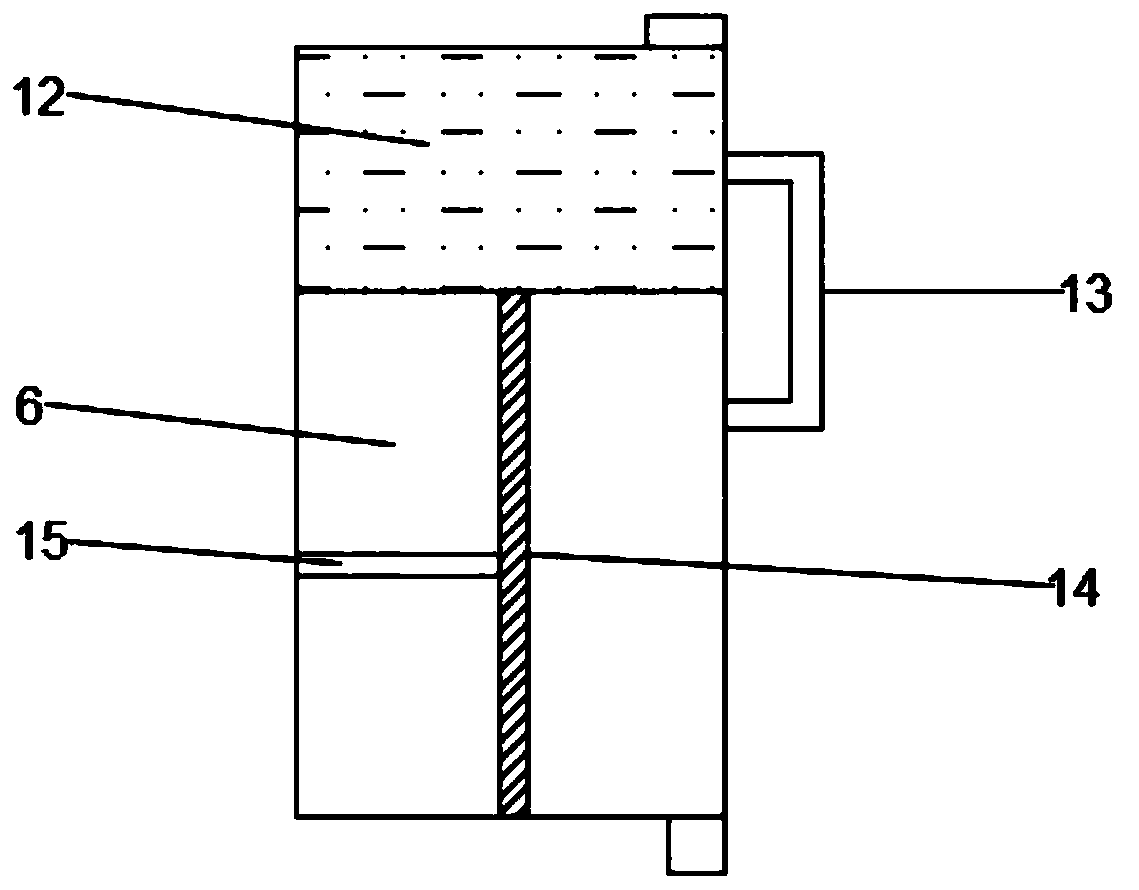

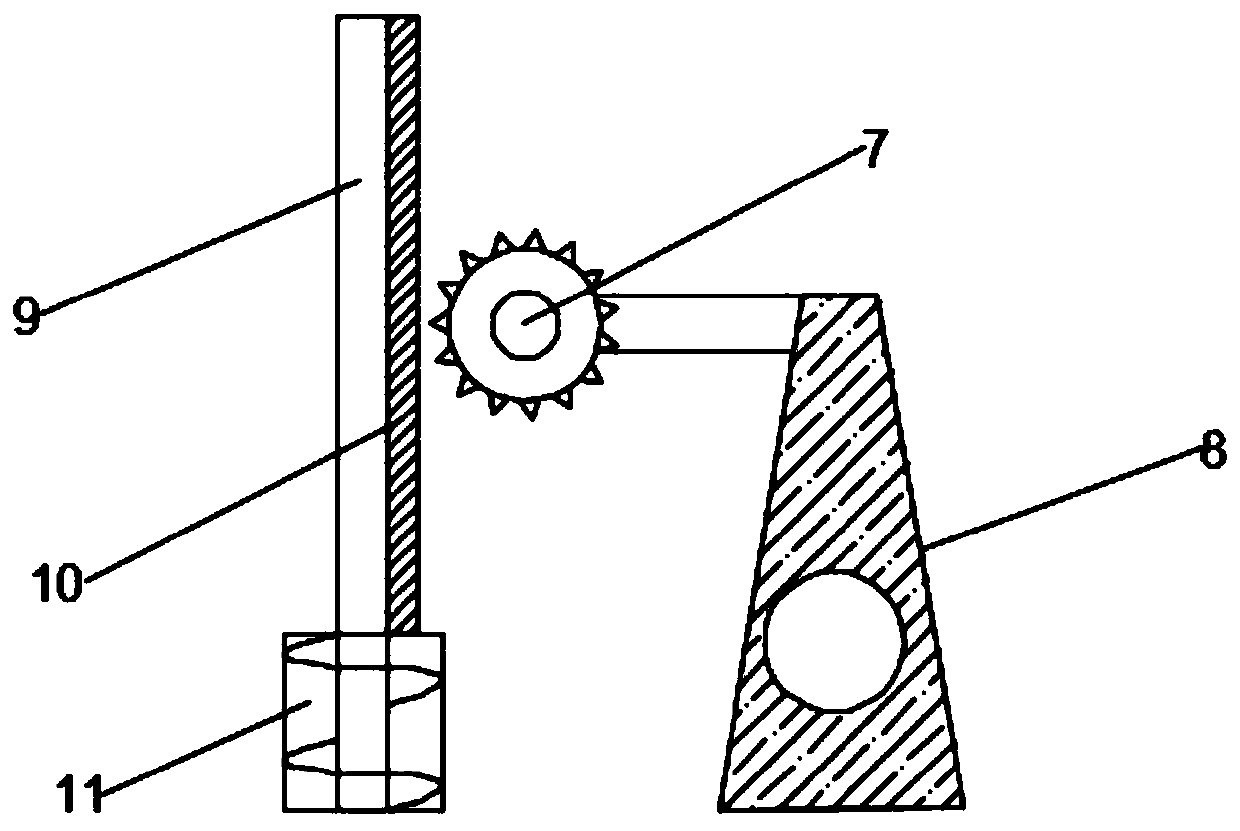

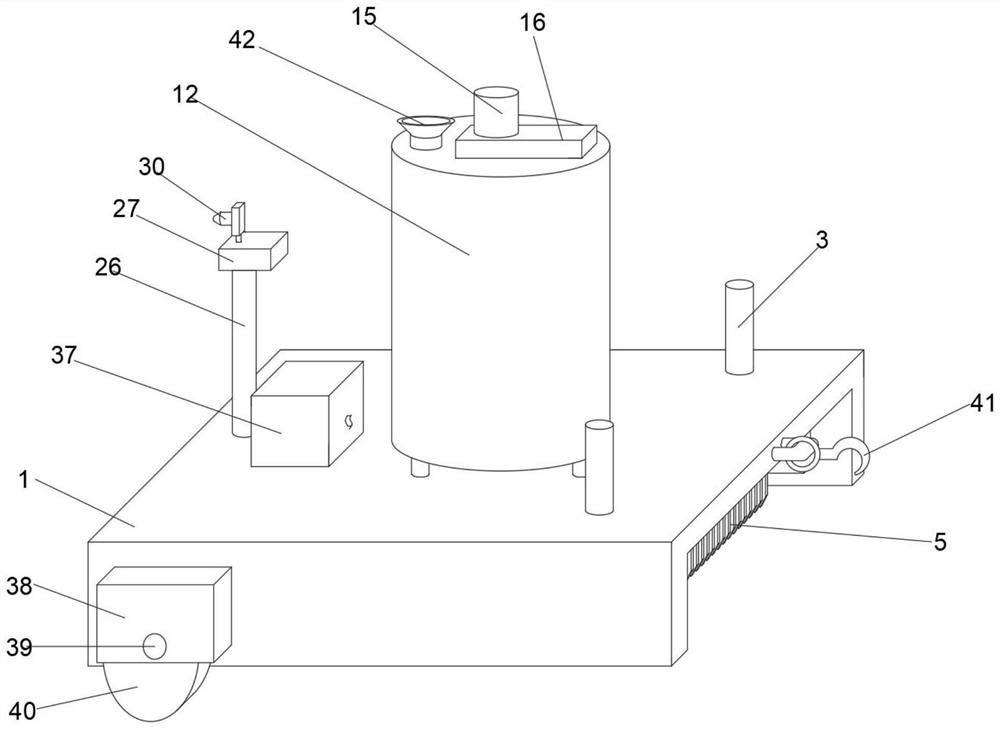

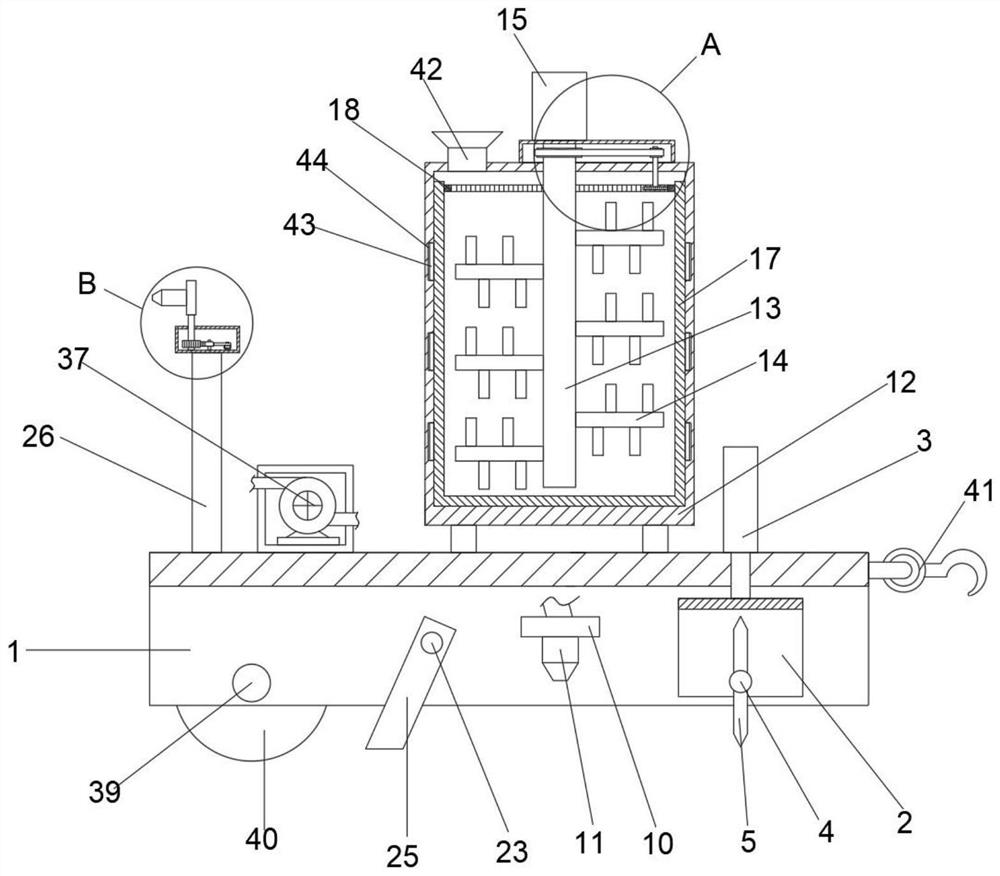

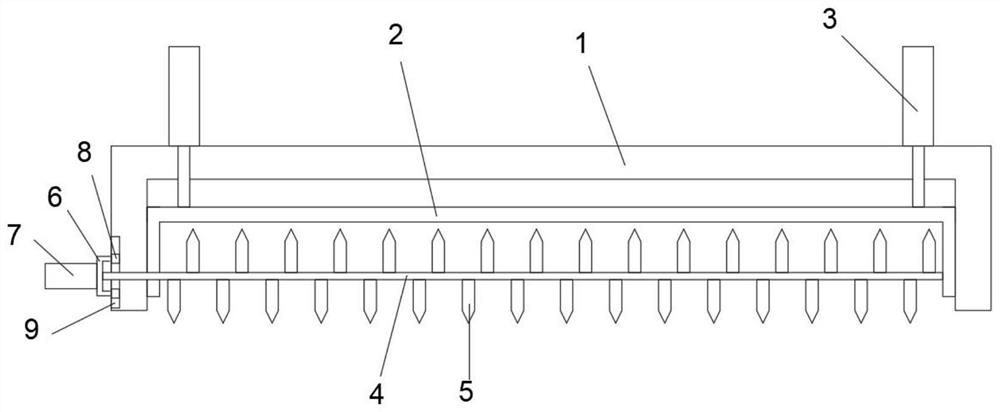

Automatic soil repairing equipment for soil pollution treatment

ActiveCN108637002AImprove governanceImprove crushing efficiencyContaminated soil reclamationGrain treatmentsEnergy consumptionPolluted soils

The invention discloses automatic soil repairing equipment for soil pollution treatment. The automatic soil repairing equipment comprises a machine body, a pulverizing cavity, a liquid chemical spraying cavity and liquid chemical mixing cavities. The upper portion of the left side of the machine body is provided with a feeding port, the lower portion of the feeding port is connected with the pulverizing cavity, and the liquid chemical mixing cavities are symmetrically welded to the two sides of the pulverizing cavity. The upper side of each liquid chemical mixing cavity is fixedly provided with a liquid chemical storage cavity, wherein the liquid chemical storage cavity is connected with the liquid chemical mixing cavity through a first liquid chemical guide pipe. The liquid chemical spraying cavity is formed below the pulverizing cavity and internally provided with a grinding plate. A discharging port is formed in the left side position of the bottom of the liquid chemical spraying cavity. The automatic soil repairing equipment has the beneficial effects that efficiency is high, and energy consumption is low; workers are prevented from making direct contact with polluted soil, andlife safety and health of maintenance personnel are guaranteed; and meanwhile, manual operation is not needed in the soil treatment process, the whole treatment work process is automatic, and the burden of the workers is relieved.

Owner:CHINA CONSTR FIRST BUREAU GRP INTERIOR FITOUT ENG

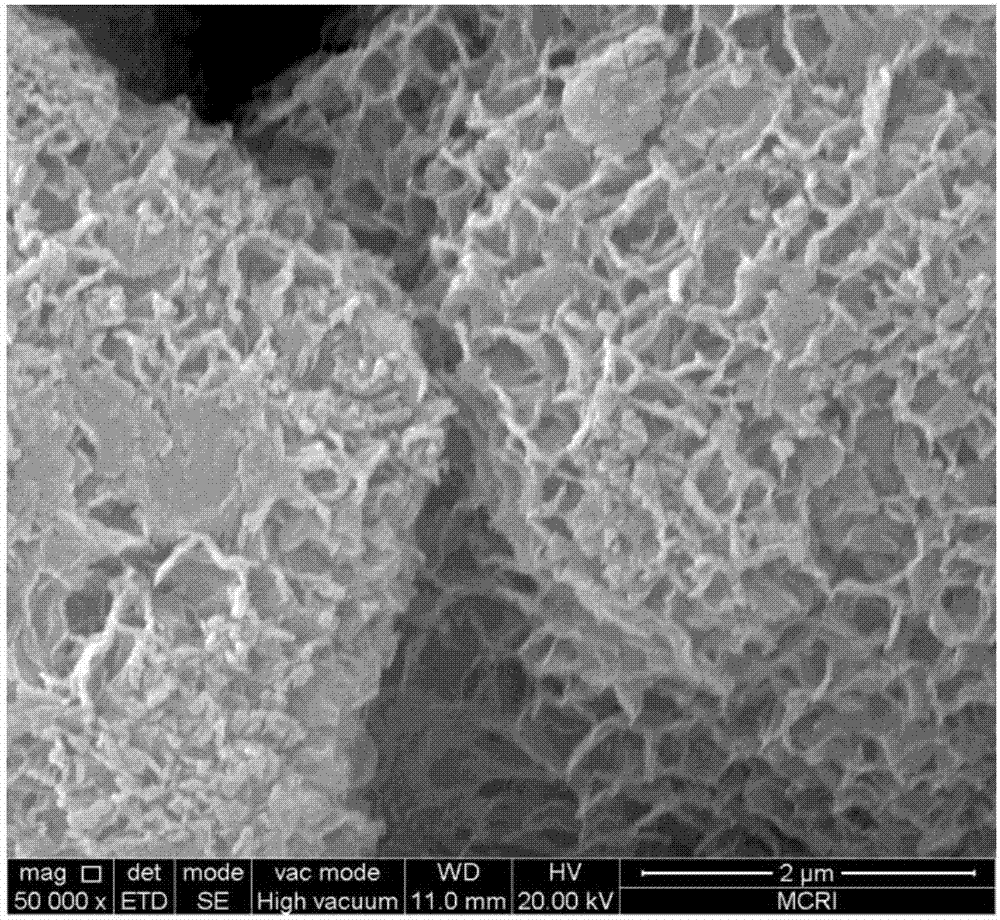

Application of synthetic calcium carbonate as high paper filler and preparation method of high paper filler

InactiveCN107287980AHigh total retentionHigh opacityInorganic compound additionFiberCalcium silicate

The synthetic calcium carbonate, as the application of papermaking filler, belongs to the papermaking technical field. The plant pulp fiber material is as the skeleton, synthetic calcium silicate power is as the filler, and the high paper filler is produced by paper-making technics. The synthetic calcium silicate power is as the hydrated calcium aluminate, and the object composition includes C-S-H polymer gel and tobermorite, and the brightness of synthetic calcium silicate power is greater than or equal to 90%, the specific surface area is greater or equal to 120 square meters per gram, the bulk density is from 0.12 grams per centimeter to 0.30 grams per centimeter, the oil-absorbed value is 120-200 milliliters per milligram, and the average grain diameter is (D50) from 12 microns to 40 microns . Meanwhile, the invention also discloses the preparation method of synthetic calcium carbonate: the synthetic calcium silicate power is the paper filler, then under the premise that paper properties are guaranteed, the usage of plant fiber can be decreased at the greatest extent. Replacing the traditional paper filler by synthetic calcium silicate power can not only reduce the usage of plant filler at the greatest extent, but also increase the retention rate of calcium carbonate, decrease the waste of filler and improve the paper ash content.

Owner:内蒙古普诺思新材料科技有限公司

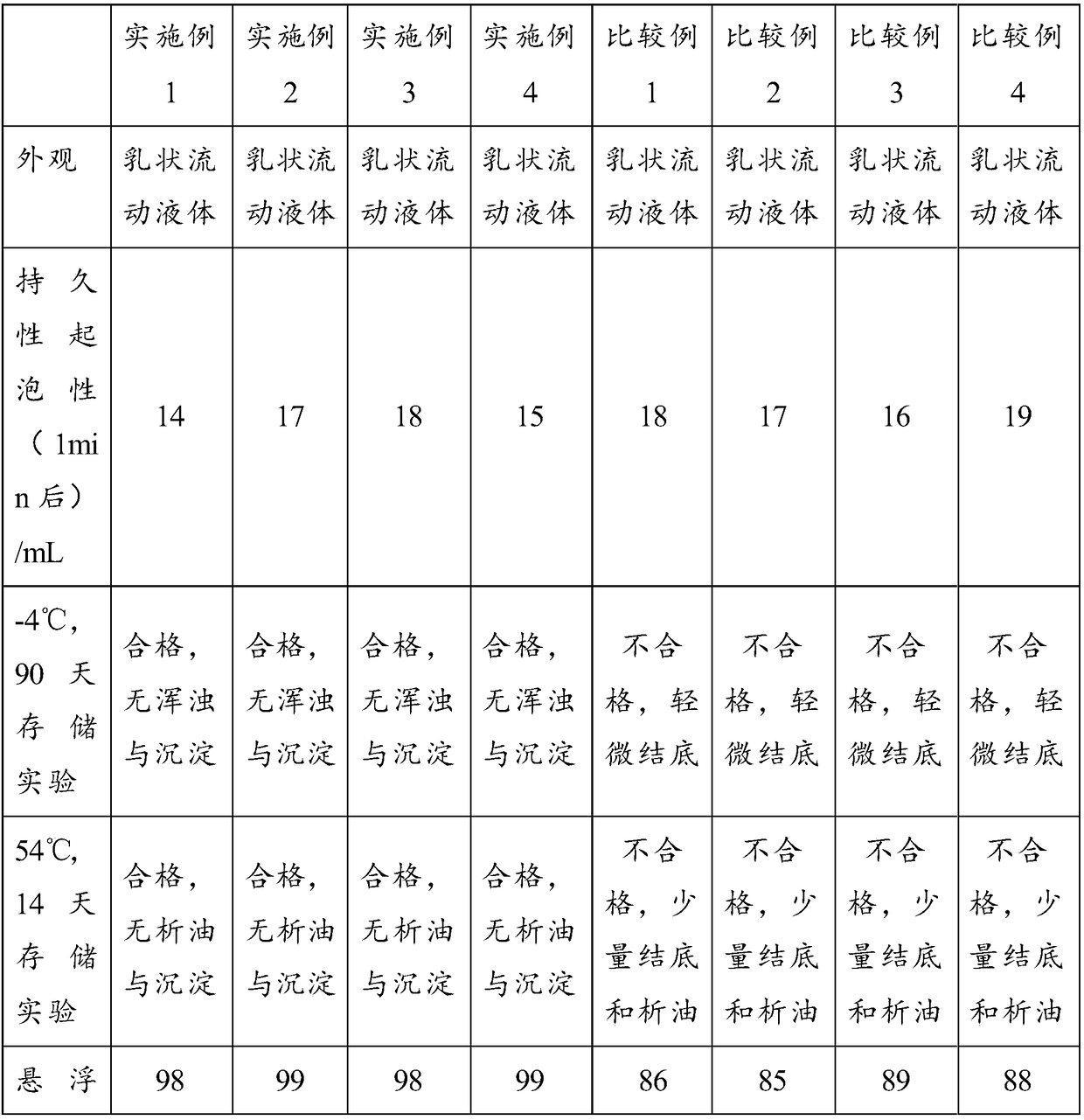

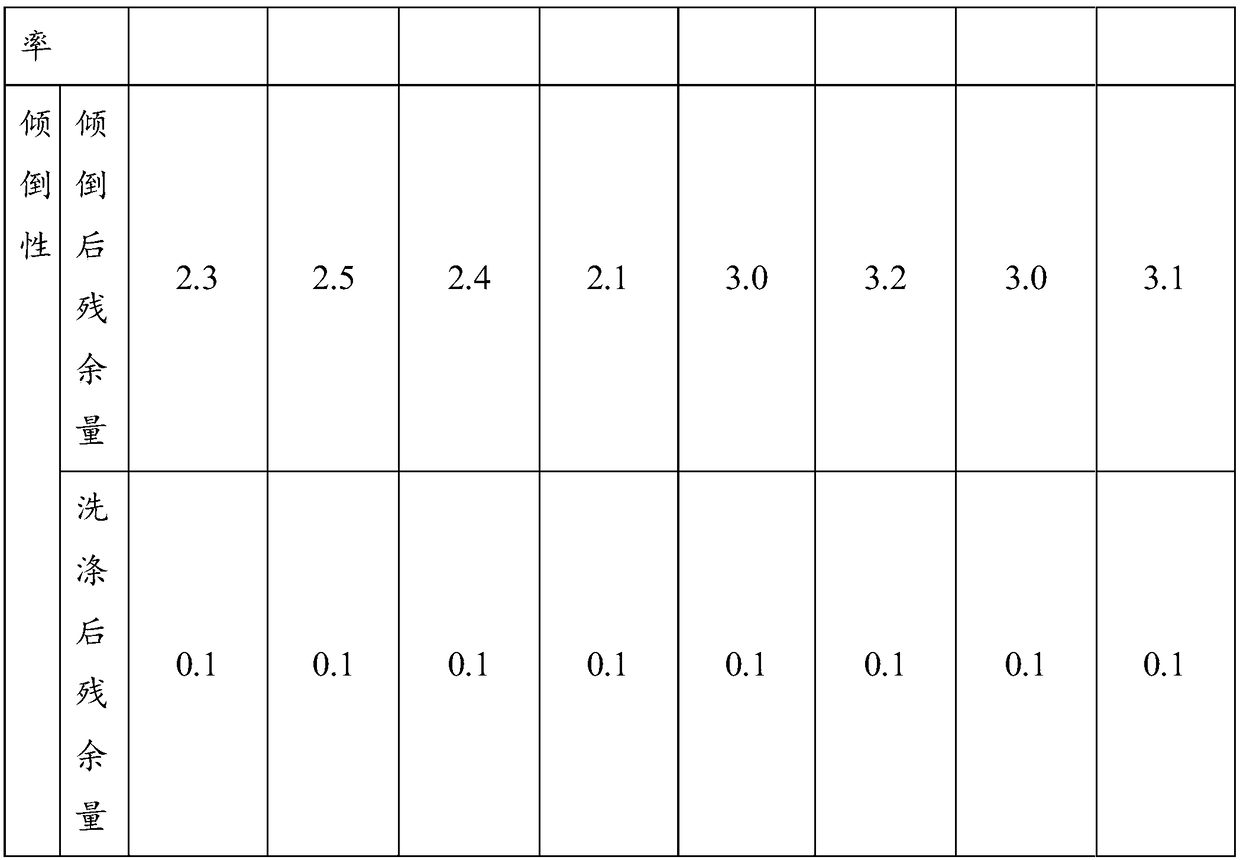

Prothioconazole dispersible oil suspension agent

The invention provides a prothioconazole dispersible oil suspension agent which is prepared from the following components in percent by weight: 10-40% of prothioconazole, 2-10% of an emulsifier, 2-8%of a polycarboxylate dispersant, 0.5-6% of a viscosity regulator, 0.1-1% of a defoamer and the balance oil. The viscosity regulator is a mixture of organobentonite and fumed silica. The prothioconazole dispersible oil suspension agent is stable in performance. Compare with a missible oil preparation, use of an organic solvent is reduced, so that the suspension agent is more environment and safer,safe to store and convey and use, is environment-friendly and meets the development direction of current pesticide preparations. Compared with a water suspension agent, the prothioconazole dispersibleoil suspension agent is more stable in performance and long in effective period, and prevents a phenomenon that a water suspended product is precipitated severely. The prothioconazole dispersible oilsuspension agent is high in stability, meets the demands on different water quality areas, high altitude areas, low temperature areas and equator near high temperature areas, and also reduces the influence of the organic solvent to the environment.

Owner:HEFEI JIUYI AGRI DEV

Flame-retardant coating fabric high in moisture-penetrability

The invention discloses a flame-retardant coating fabric high in moisture-penetrability. The flame-retardant coating fabric high in moisture-penetrability comprises a first base coating and a second base coating, wherein the first base coating is obtained by drying a sizing agent which is prepared from the following components in parts by mass: 100 parts of polyurethane resin, 38-42 parts of bromoethane, 19-21 parts of diantimony trioxide, 4.5-5.5 parts of zinc borate, 4-5 parts of a bridging agent, 1.6-2 parts of an accelerant, 1.4-1.6 parts of a washable agent and 9-11 parts of phosphate ester flame-retardant oil. The second base coating is obtained by drying a sizing agent which is prepared from the following components in parts by mass: 100 parts of polyurethane resin, 38-42 parts of bromoethane, 19-21 parts of diantimony trioxide, 4.5-5.5 parts of zinc borate, 4-5 parts of the bridging agent, 1.6-2 parts of the accelerant, 1.4-1.6 parts of the washable agent and 9-11 parts of phosphate ester flame-retardant oil. The flame-retardant coating fabric high in moisture-penetrability is small in smoke generation quantity, free of molten drop, high in flame-retardant effect and highly washable; the flame-retardant substance has a small possibility of hydrolyzing.

Owner:KUNSHAN HUAYANG NEW MATERIAL

Chemical plant waste gas treatment apparatus

InactiveCN108273347ACompact structureEasy to installCombination devicesGas treatmentWaste treatmentChemical plant

The invention discloses a chemical plant waste gas treatment apparatus, comprising a base. A settling tank is welded to one end of the top of the base. A blower is arranged on one side of the bottom of the settling tank. The bottom of the blower is mounted at the top of the base. An intake port of the blower is provided with an intake pipe by welding. An exhaust port of the blower is communicatedwith an intake port in one side of the bottom of the settling tank; a spray pipe is welded to the inner bottom end of the settling tank, and the bottom of the spray pipe is communicated with a nozzle.The chemical plant waste gas treatment apparatus is compact in structure and simple to mount, and ensures sufficiency of waste gas treatment as adsorbing, settling, filtering and disinfecting are integrated herein; the exhaust pipe is set to an S-shaped coil exhaust pipe, waste gas can be fully disinfected, air pollution is prevented, and emission safety is ensured for waste gas; the chemical plant waste gas treatment apparatus is special for treatment of waste gas and is widely applicable to the field of waste gas emission for chemical plants.

Owner:潘建平

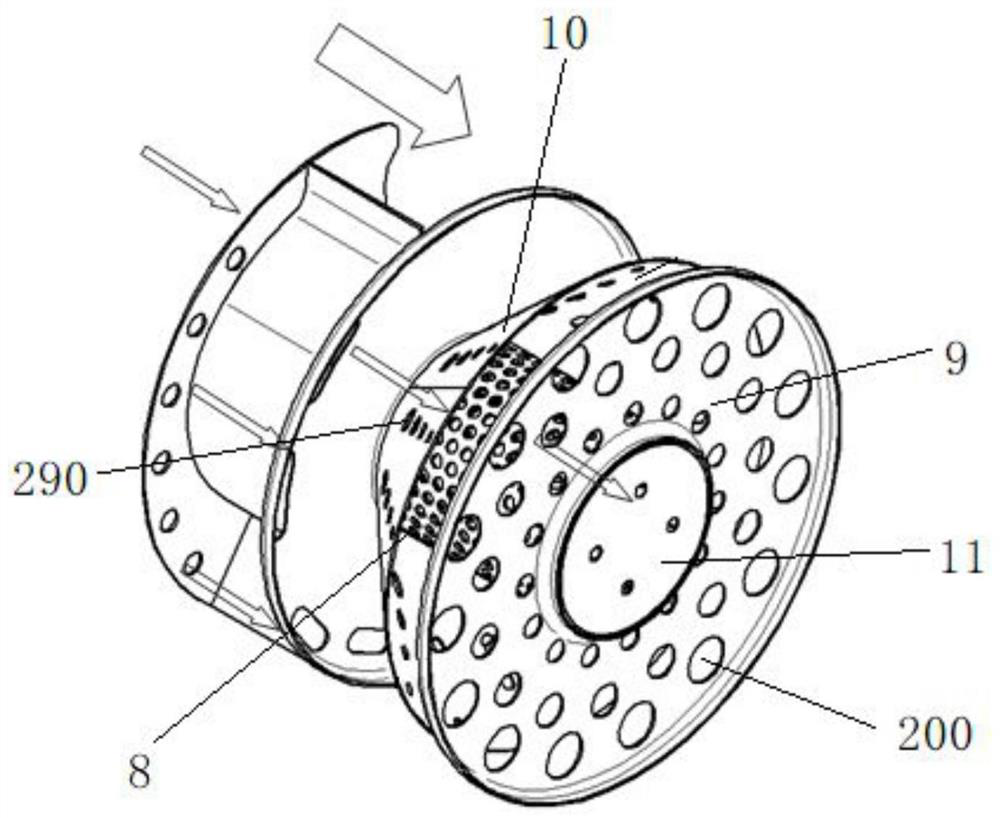

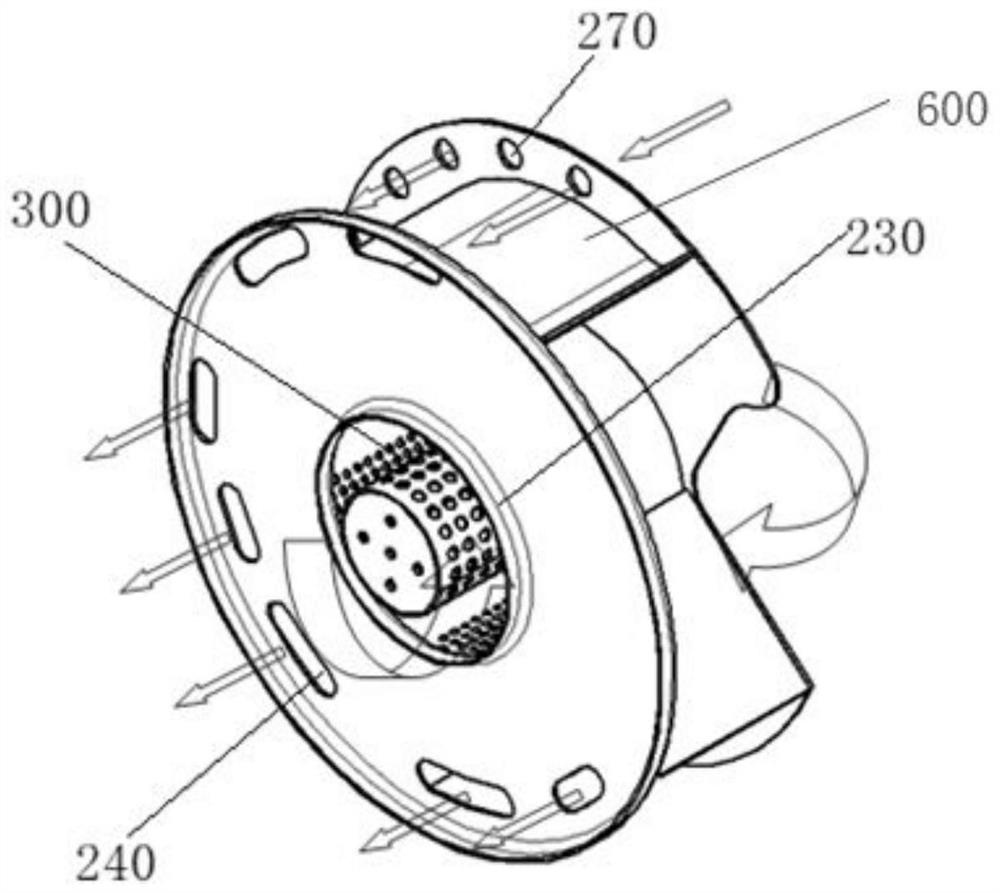

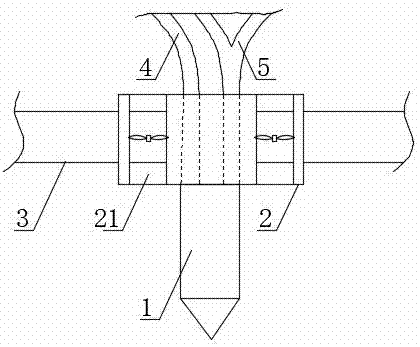

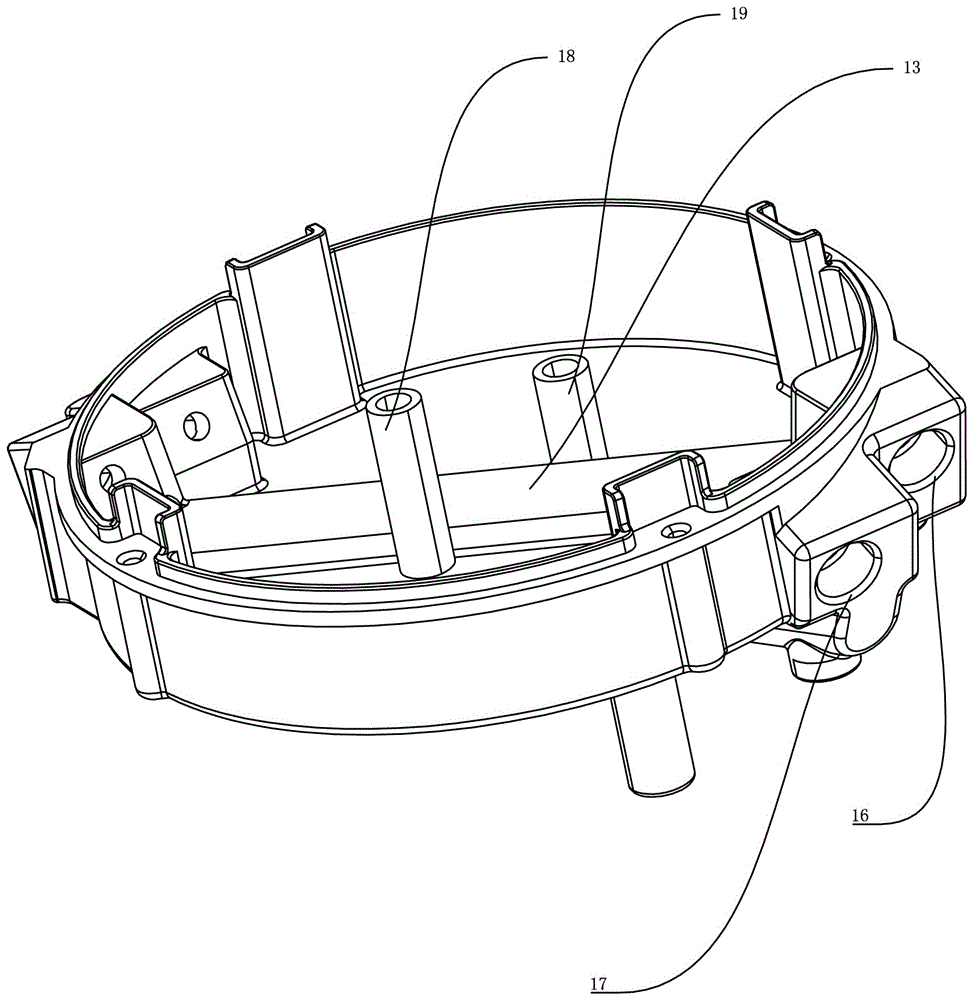

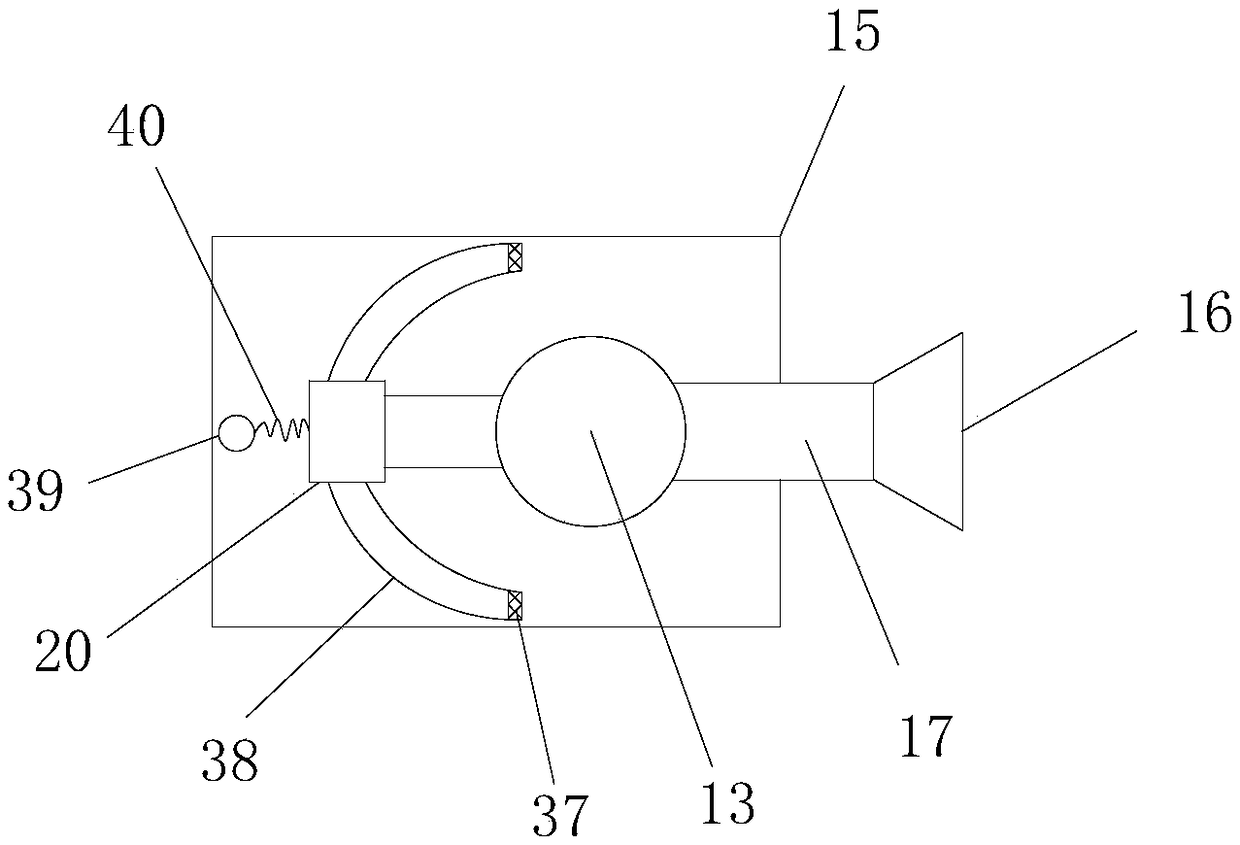

SCR urea solution mixer

ActiveCN112983604AIncrease surface temperatureExtended Hybrid PathwayInternal combustion piston enginesExhaust apparatusEngineeringMechanical engineering

The invention discloses an SCR urea solution mixer. The mixer is a gas through structure cylinder arranged at a motor vehicle tail gas outlet, and after the urea solution in the mixer is sprayed and is mixed with the tail gas for the first time, the urea solution is continuously mixed with the tail gas for at least one time, wherein the first-time mixing is that the urea solution is tangentially sprayed along the tail gas flow direction and then is radially and spirally mixed, and the subsequent mixing is that the first-time mixed gas flow is sprayed along the radial direction and is remixed with the tail gas for at least one time. According to the mixer, the atomized urea solution and the tail gas entering the mixer are guided and subjected to first-time atomization decomposition by adopting a spiral flow guide plate, then subjected to second-time atomization thermal decomposition and guided into a flow equalizing pipe, tail gas flow is supplemented through the outer side, and third-time decomposition is conducted through the flow equalizing plate. According to the mixer, the mixing stroke is more reasonable, the mixing path of the urea solution and the tail gas is prolonged, mixing is more uniform and sufficient, urea thermal decomposition is better, the crystallization risk is avoided, and the conversion efficiency of NOx in the tail gas is improved.

Owner:SINOCAT ENVIRONMENTAL TECH

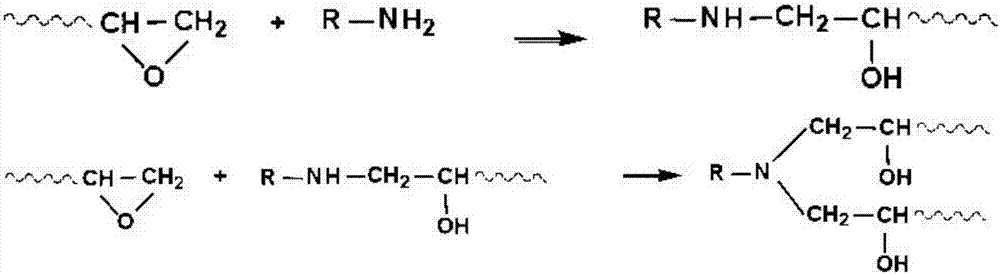

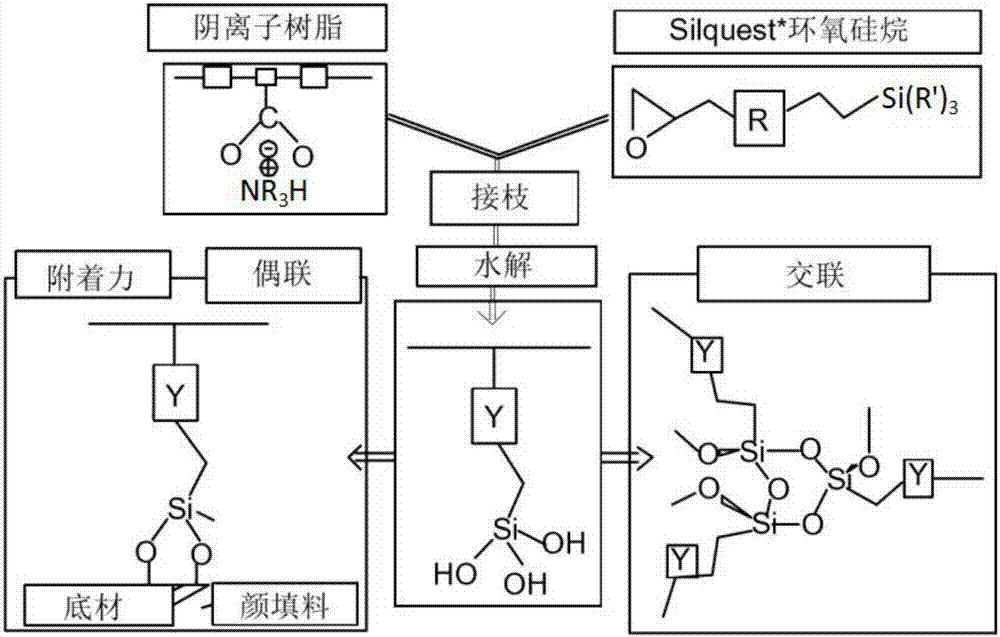

Aqueous organosilicon modified acrylic acid primer-topcoat vehicle axle coating and preparation method thereof

InactiveCN107267003AIncrease the degree of cross-linkingImprove water resistanceFireproof paintsAntifouling/underwater paintsSolventDefoamer

The invention relates to an aqueous organosilicon modified acrylic acid primer-topcoat vehicle axle coating and a preparation method thereof. The vehicle axle coating is prepared through mixing a component A with a component B according to a ratio of 1:1; the component A comprises, by weight, 15-20 parts of deionized water, 3-5 parts of a dipropylene glycol methyl ether solvent, 0.5-1 part of a wetting agent, 0.5-1 part of a leveling agent, 15-20 parts of polyamide resin, 50-60 parts of an aqueous color paste, 0.5-1 part of an antifoaming assistant, 1-2 parts of an aqueous low-shear thickening assistant, 1-2 parts of an aqueous middle-shear thickening assistant and 0.5-1 part of an aqueous high-shear thickening assistant; and the component B comprises, by weight, 80-85 parts of an aqueous organosilicon modified acrylic emulsion, 3-5 parts of Texanol, 3-5 parts of an adhesion promoter, 5-10 parts of deionized water and 0.5-1 part of an antifoaming agent. The aqueous acrylic emulsion undergoes organosilicon and epoxy grafting modification, so the aqueous organosilicon modified acrylic acid primer-topcoat vehicle axle coating has improved resistance to water, chemicals and weather, and has excellent corrosion resistance.

Owner:广东鑫皇冠新材料有限公司

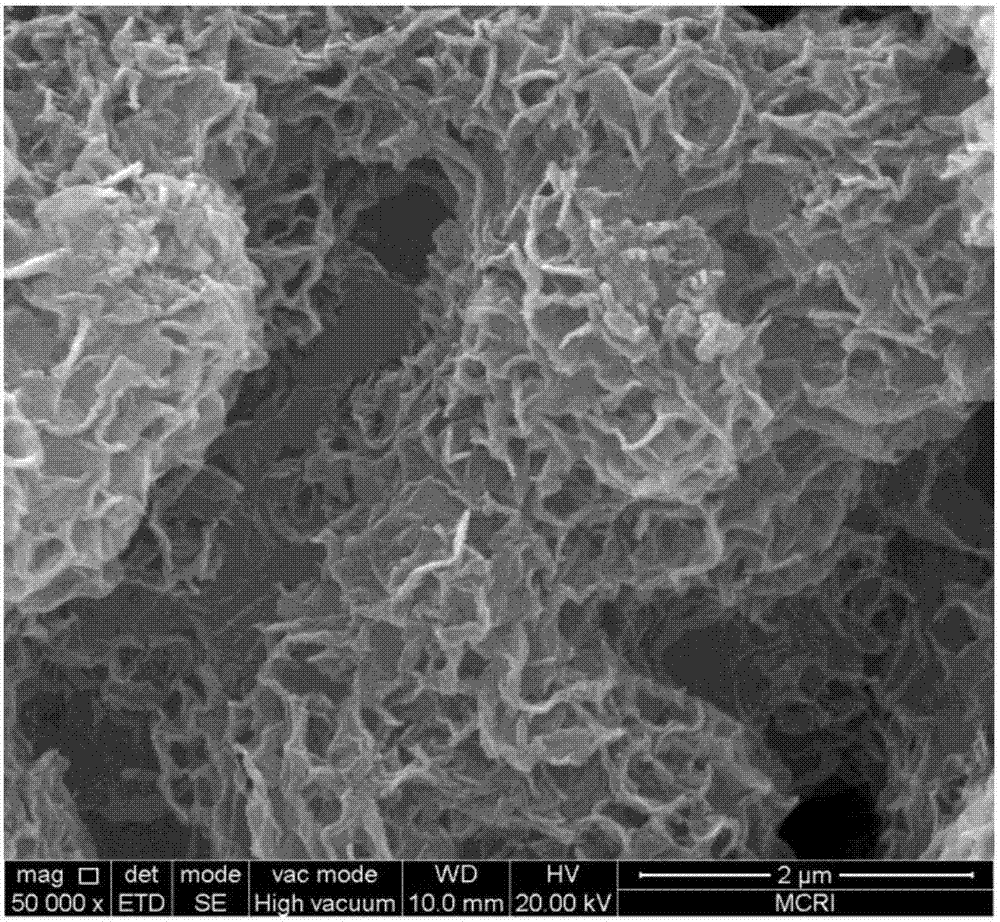

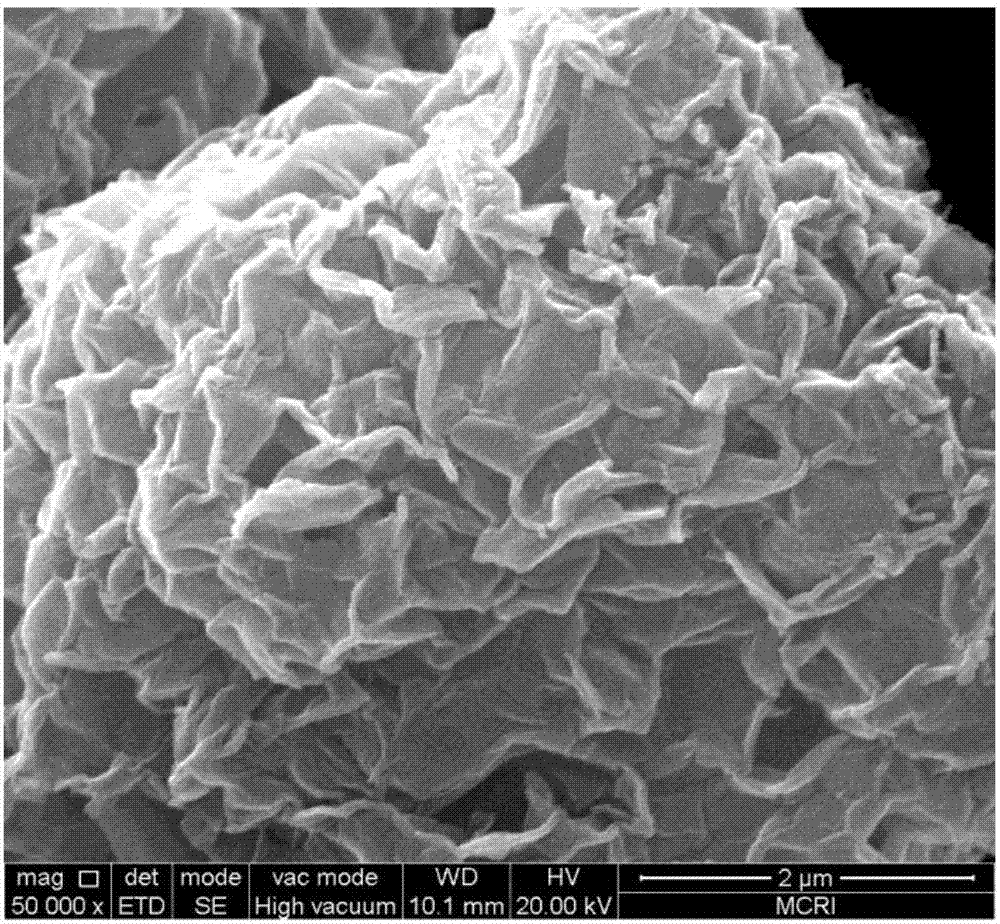

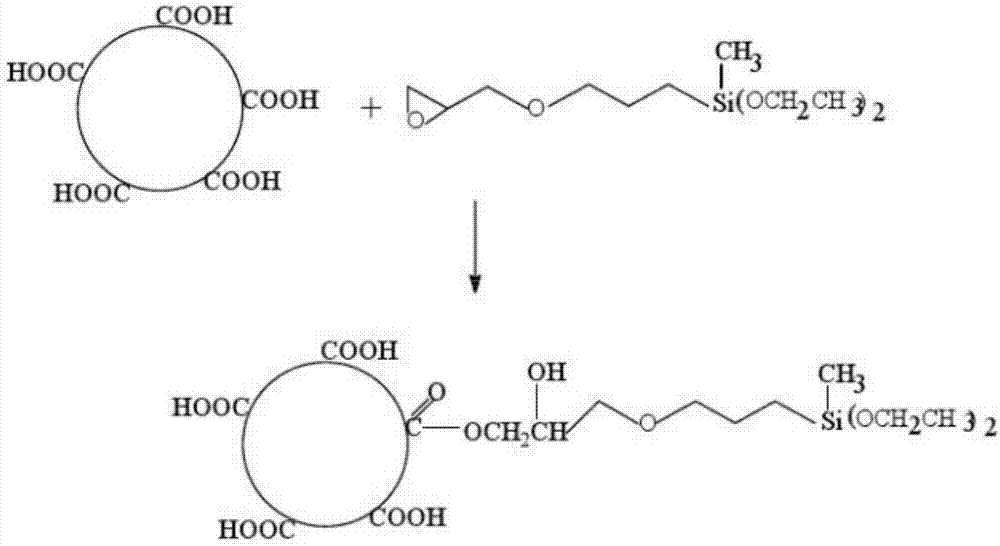

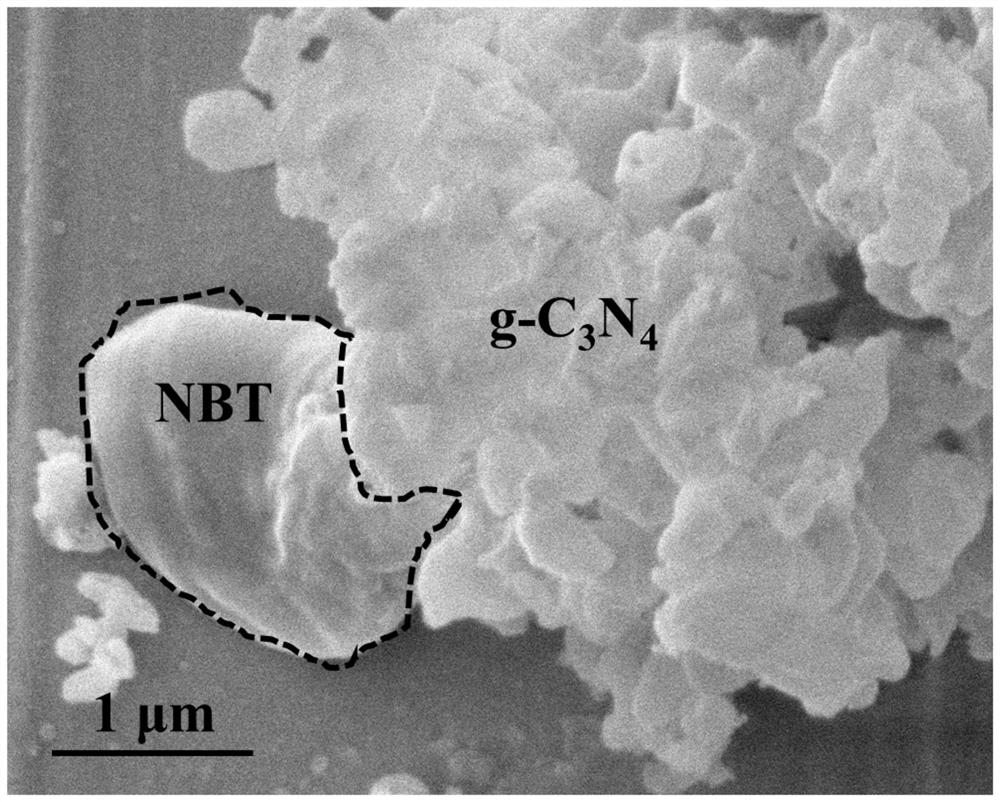

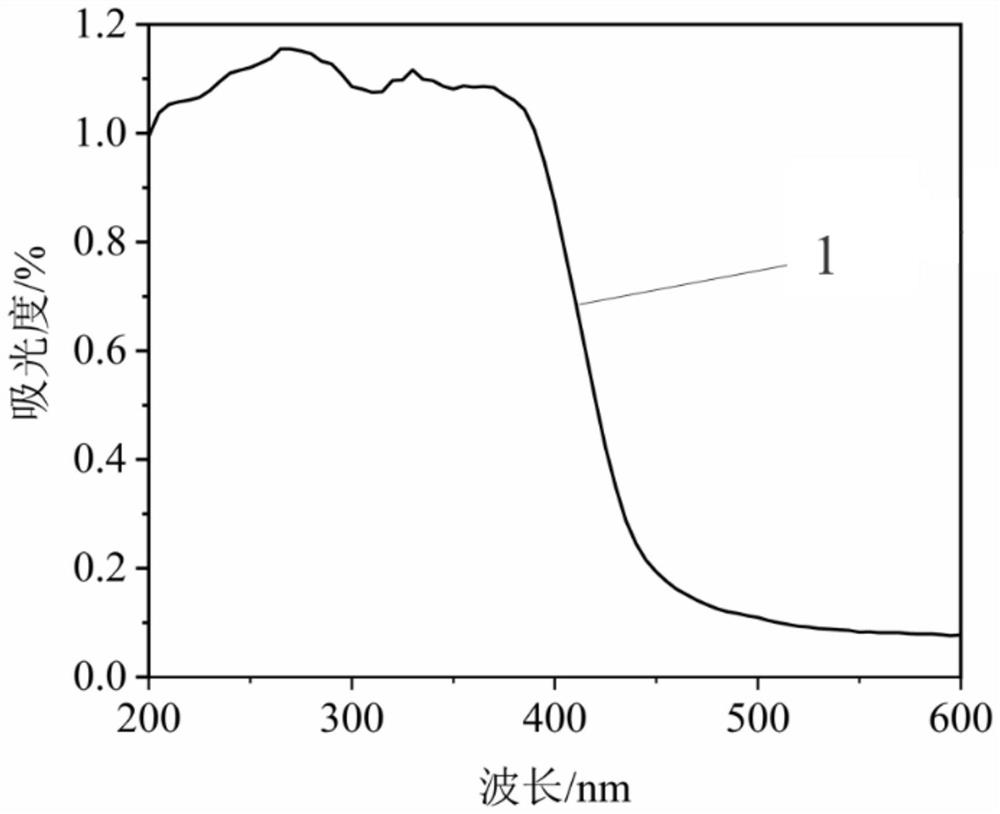

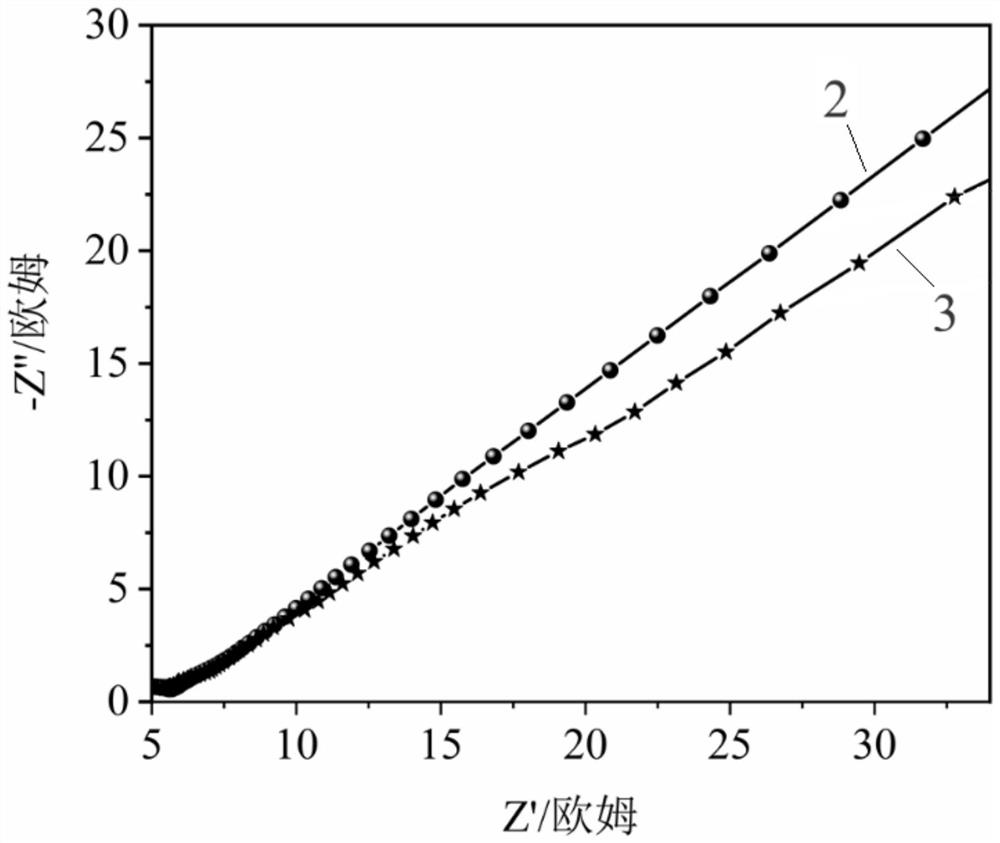

Sodium bismuth titanate/graphite phase carbon nitride heterojunction piezoelectric photocatalyst and preparation method thereof

InactiveCN113198505AMix thoroughly mix wellWell mixedWater/sewage treatment by irradiationWater treatment compoundsOrganic dyeSodium bismuth titanate

The invention discloses a sodium bismuth titanate / graphite phase carbon nitride heterojunction piezoelectric photocatalyst and a preparation method thereof, and solves the problems that an existing heterojunction photocatalyst is relatively complex in preparation and relatively high in cost, and the catalytic activity of g-C3N4 cannot be fully improved to the maximum extent. The graphite-phase carbon nitride photocatalyst is synthesized through a one-step thermal polymerization method, sodium bismuth titanate nanoparticles are synthesized through a one-step hydrothermal process, then the NBT / g-C3N4 heterojunction piezoelectric photocatalyst is obtained through simple grinding, mixing and calcination, and g-C3N4 can absorb part of visible light to generate photon-generated carriers. In the stirring process, charges are generated on the surface of the piezoelectric material NBT due to external pressure, and meanwhile, a built-in electric field is formed at the interface of the two materials through piezoelectric polarization to drive photo-induced electrons and holes to move in opposite directions. By controlling the ratio of NBT to g-C3N4, piezoelectric photocatalysts with different photocatalytic properties can be obtained and used for organic dye degradation and hydrogen production.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

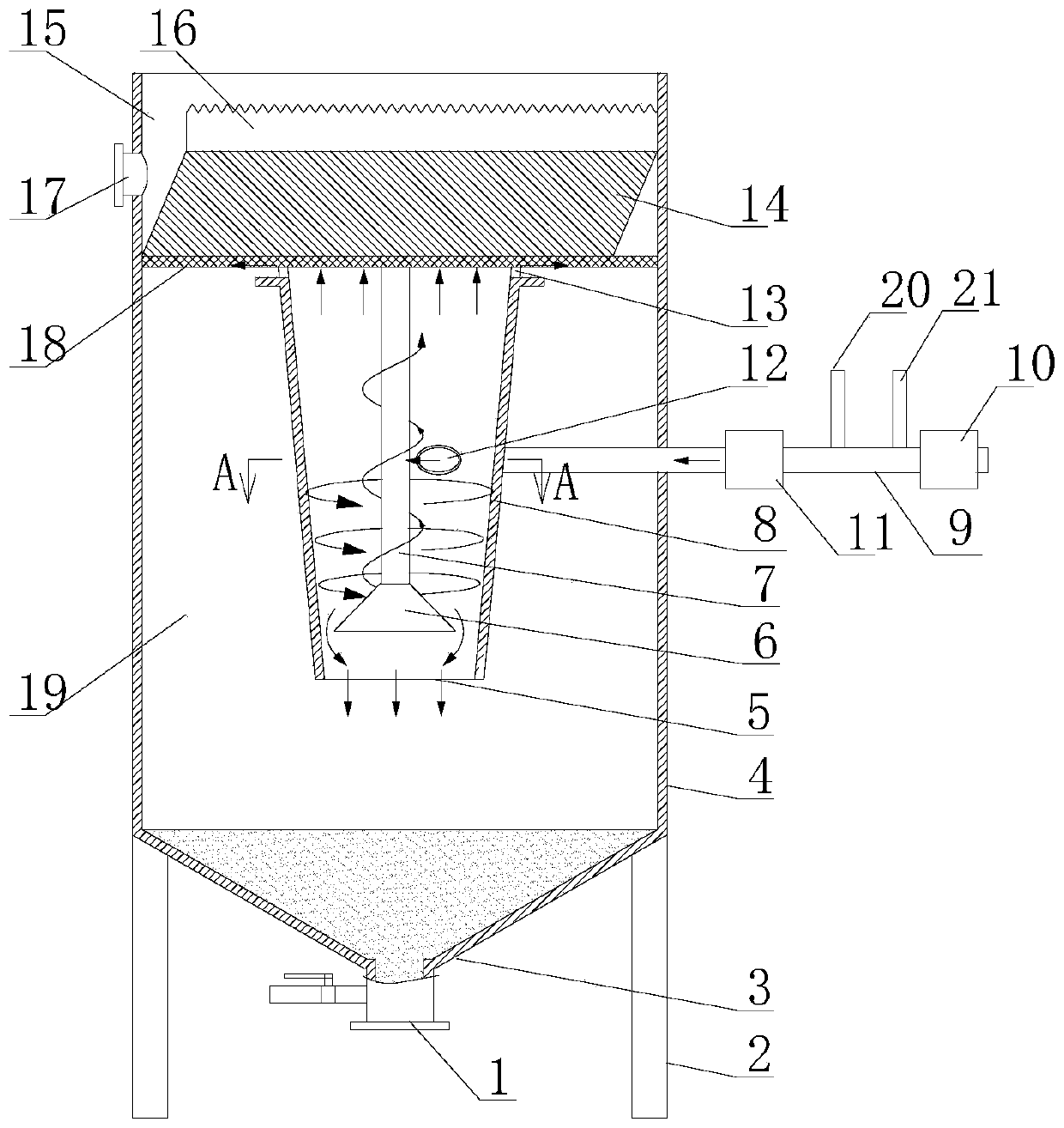

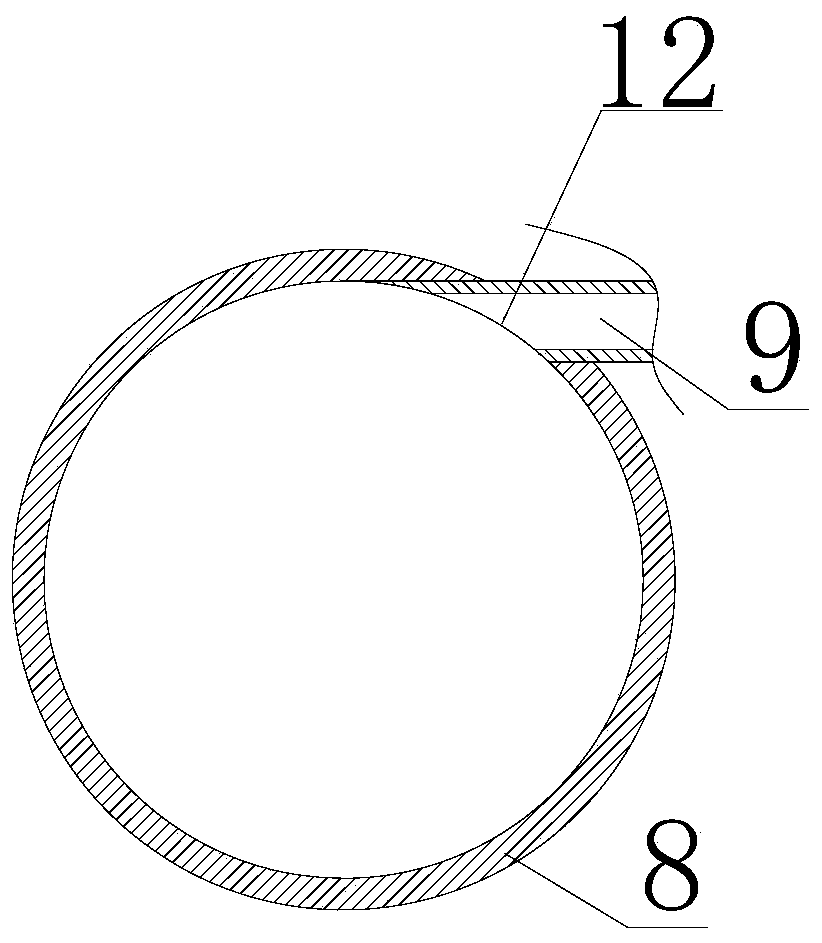

Efficient sewage precipitation device and method

PendingCN111330317AReduce mass transfer resistanceImprove sludge activitySettling tanks feed/dischargeCentrifugal force sediment separationSewageMechanical engineering

The invention relates to an efficient sewage precipitation device and method, and belongs to the technical field of sewage precipitation separation. The device comprises a body, an inner cavity of thebody is divided into three cavities which are a clear water cavity, a sewage cavity and a sludge cavity from top to bottom, a packing layer mounted on a net-shaped supporting plate is arranged between the clear water cavity and the sewage cavity, the edge of the net-shaped supporting plate is mounted on the inner wall of the body, a solid-liquid separation barrel is mounted at the bottom of the packing layer, a stand column is arranged in the solid-liquid separation barrel, the top of the stand column is fixed at the bottom of the packing layer, a conical baffle is installed at bottom of thestand column, the small-diameter end of the conical baffle is connected with the stand column, the conical baffle plate is positioned in the solid-liquid separation barrel, a water inlet is formed inthe side wall of the solid-liquid separation barrel, the water inlet is formed in the middle of the solid-liquid separation barrel and is connected with a water inlet pipe, the water inlet pipe penetrates through the body and is arranged in the tangential direction of the outer wall of the solid-liquid separation barrel, an overflow port is formed in the side wall of the top of the solid-liquid separation barrel, and an opening is formed in the bottom of the solid-liquid separation barrel. The technical problem of low precipitation efficiency of a sewage precipitation technology in the prior art is solved.

Owner:烟台和盛康洁环保科技有限公司

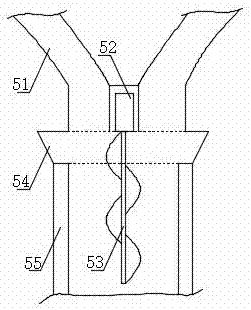

Pre-fusion 3D printer spray head

InactiveCN107139471AIncrease varietyImproved performanceManufacturing material handlingApplying layer meansEngineering3D printing

The invention discloses a pre-fusion 3D printer spray head. The pre-fusion 3D printer spray head comprises a printer spray head body, a driving device and a driving transverse rod; the printer spray head body is fixedly connected to the middle of the lower end of the driving device, the driving device is connected to the driving transverse rod in a sleeving mode, and the left end and the right end of the driving device are each provided with a UFP adsorption device; a homogenous material feeding pipe and a mixed material pre-fusion feeding pipe are connected to the upper end of the printer spray head body; the mixed material pre-fusion feeding pipe comprises a Y-shaped feeding pipe, a micromotor, a material mixing rotating wheel, a heat insulating layer and a heating section; and the lower end of the Y-shaped feeding pipe is provided with the heat insulating layer, and the lower end of the heat insulating layer is provided with the heating section. According to a 3D printer, two different materials can be subjected to pre-fusion mixing by arranging the structure of the mixed material pre-fusion feeding pipe, the number of kinds of printing materials is increased, the material performance is improved, more possibilities and higher practicability are provided for 3D printing, and the pre-fusion 3D printer spray head is suitable for being widely popularized.

Owner:芜湖智享三维打印服务有限公司

Traditional Chinese medicine ointment for treating sore toxins and preparation method thereof

InactiveCN104958553AHigh content of active ingredientsGood curative effectInorganic active ingredientsAerosol deliveryBletilla striataBULK ACTIVE INGREDIENT

The invention discloses a traditional Chinese medicine ointment for treating sore toxins. The traditional Chinese medicine ointment is prepared from the following materials in parts by weight: 35 to 53 parts of cottonrose hibiscus leaves, 31 to 48 parts of raw rhubarb, 18 to 32 parts of burdock, 20 to 30 parts of bletilla striata, 20 to 30 parts of realgar, 3 to 4 parts of probiotics stock solution and rice wine. The invention further provides a preparation method of the traditional Chinese medicine ointment for treating the sore toxins. According to the traditional Chinese medicine ointment provided by the invention, the manufacturing method is simple, the probiotics stock solution is utilized to ferment, the traditional Chinese medicines are predigested, decomposed and converted, and macromolecular substances of the traditional Chinese medicines are converted into small molecular substances which are favorable for being absorbed by human skin, so that the content of active ingredients of the traditional Chinese medicine ointment is increased, the curative effect of the traditional Chinese medicine ointment is improved, and additionally, harmful toxicity of the medicines can be removed through fermentation; expired yogurts are used as protein sources of the probiotics stock solution, so that waste is fully used, and three kinds of bacterial powder including lactobacillus powder, bifidobacteria powder and yeast powder are utilized, so that incomplete fermentation caused by single cultures is avoided.

Owner:曾德锋

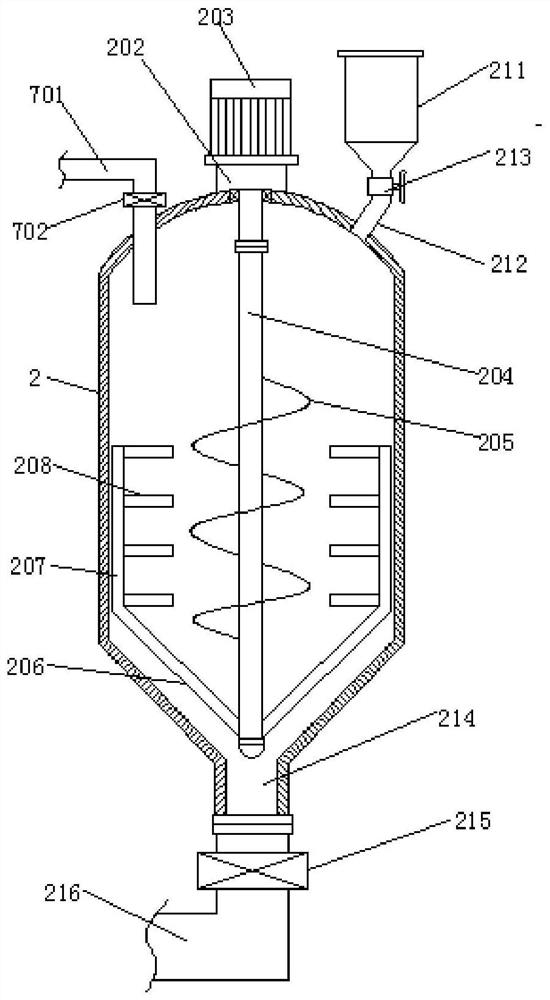

Material mixing device for molding bag shell

The invention relates to a material mixing device for molding a bag shell. The material mixing device a material mixing bin, a swivel nut arranged inside the material mixing bin in the vertical direction, a screw arranged in the swivel nut, a driving mechanism used for driving the screw to rotate and a material adding hopper inserted in from the side portion of the material mixing bin and communicated with the swivel nut, wherein the upper end of the screw is exposed out of the upper end of the swivel nut and is screwed out from the top of the material mixing bin, and a cavity is formed by the inner wall and the top of the material mixing bin and the periphery of the swivel nut; and a material discharging pipe for discharging the materials is arranged on the material mixing bin. According to the material mixing device, multiple materials are stirred and conveyed firstly through the screw and then are further mixed in a freely-scattering manner, so that the materials are evenly mixed sufficiently, the quality of the bag shell is guaranteed, the scrapping number is reduced accordingly, and cost is saved.

Owner:SUZHOU HUAXIANG LUGGAGE MFGR CO LTD

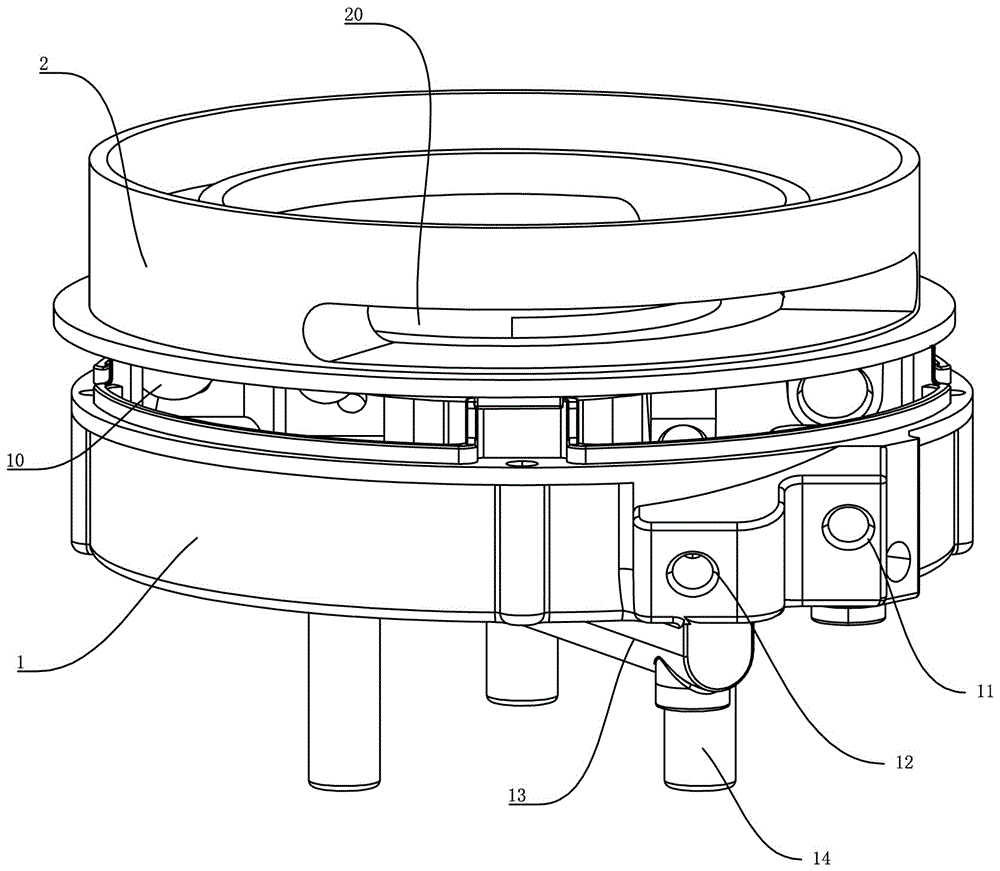

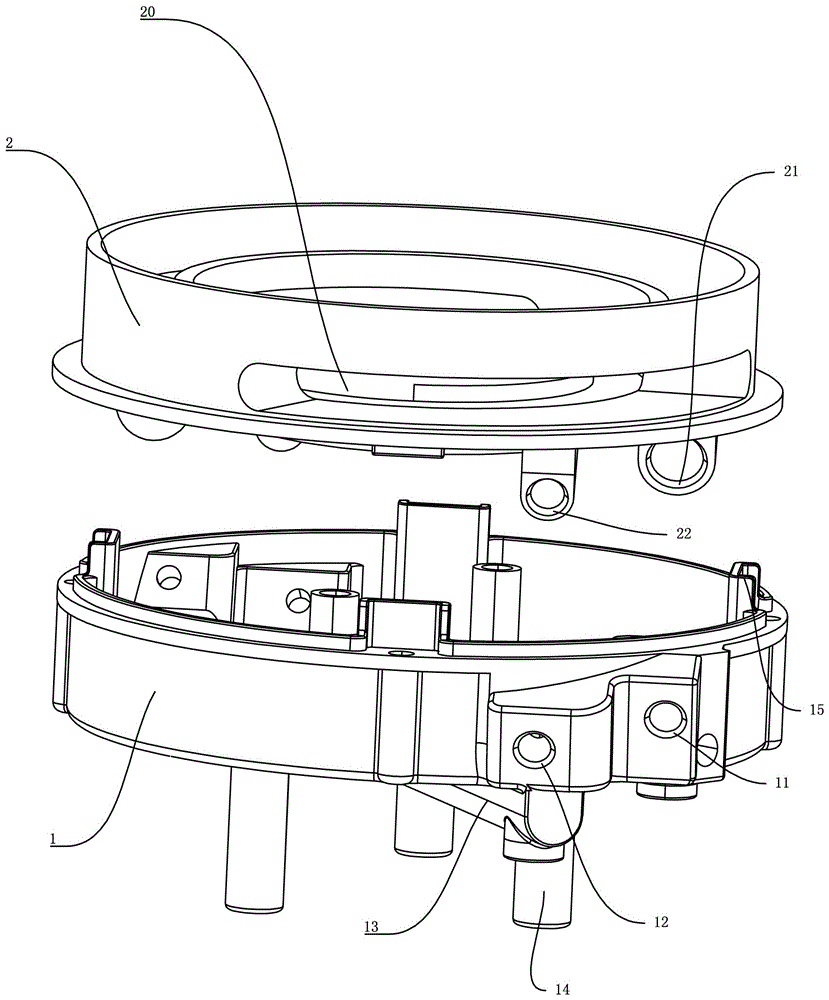

Two-time upside-entrainment burner

ActiveCN106369603APrevent leakageIncrease air intakeGaseous fuel burnerEngineeringThermocouple device

The invention discloses a two-time upside-entrainment burner. The two-time upside-entrainment burner comprises a base and a support. Both the base and the support are integrally formed. The support is arranged on the base. Primary air inlets are formed between the base and the support. A thermocouple is arranged on the base. Outer air inlet nozzles and inner air outlet nozzles are obliquely arranged on the base. Outer ejecting pipes and inner injecting pipes are obliquely arranged on the support. The support is provided with an outer annular groove, a middle annular groove and an inner annular groove, wherein the outer annular groove communicates with the outer air inlet nozzles through the outer ejecting pipes, and the inner annular groove communicates with the inner air inlet nozzles through the inner ejecting pipes. The support is provided with a secondary air inlet which communicates with the middle annular groove. According to the two-time upside-entrainment burner, air input is large, an ejecting pipeline is long, and fuel gas is evenly mixed with air and can be burnt sufficiently; and the thermocouple is arranged on the base so that fuel gas leakage can be prevented. Furthermore, the base and the support are integrally formed, so that manufacturing and assembling are easy and convenient.

Owner:NINGBO FENGTENG GAS APPLIANCE CO LTD

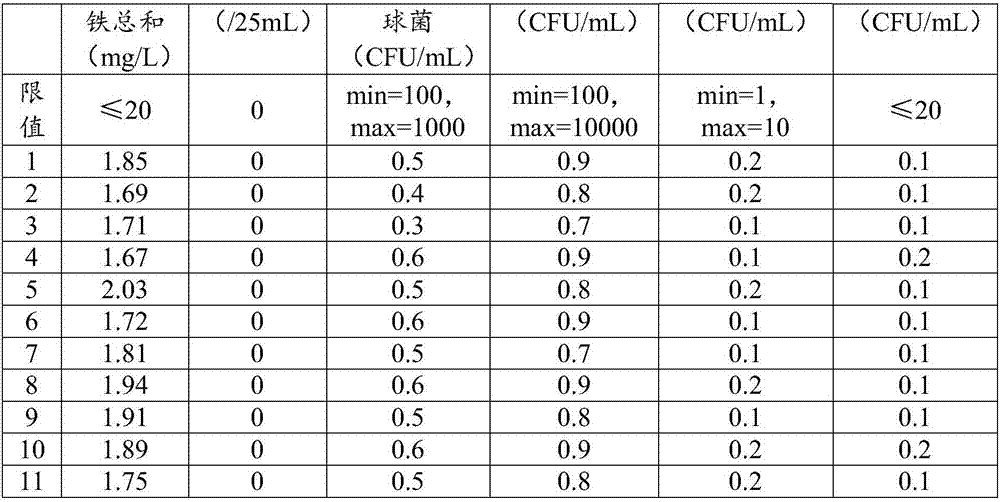

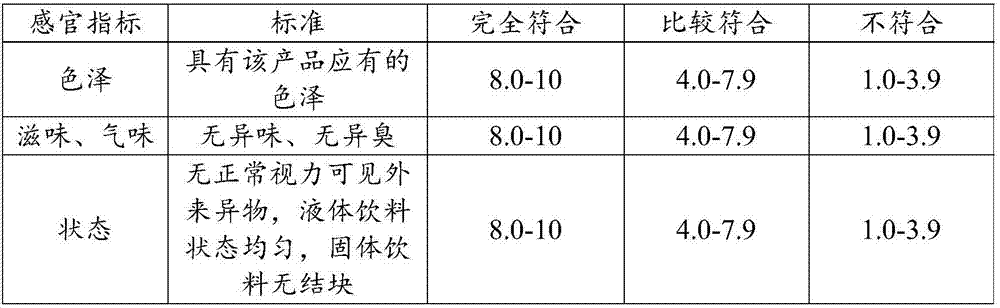

Moringa oleifera plant beverage and preparation method thereof

InactiveCN107348289ADeworming sleep qualityImprove sleep qualitySugar food ingredientsFood ingredient as colourNutrientCaffeine

The invention discloses a moringa oleifera plant beverage and a preparation method thereof, relates to the technical field of health beverages, and aims to improve the technical problems in the prior art that the taking convenience degree and crowd accepting degree of a moringa oleifera leaf suspension beverage are relatively low. The moringa oleifera plant beverage disclosed by the invention does not contain caffeine, contains rich nutrients, has a health-care function and better taste, is suitable for people of all ages, and is suitable for various crowds to drink. The invention also provides a preparation method of the moringa oleifera plant beverage. The preparation method comprises the following steps: fully extracting moringa oleifera leaves to obtain moringa oleifera leaf extract, then mixing the moringa oleifera leaf extract with other raw material components, and controlling conditions, such as temperature and treatment technology, in preparation processes, thereby finally obtaining the moringa oleifera plant beverage product which contains rich nutrients and is delicious with slight sweetness and sour.

Owner:尹飞

Pigment stirring machine for textile printing and dyeing

InactiveCN108579527AMix well mix well mix wellMix thoroughly mix wellRotary stirring mixersTransportation and packagingTextile printerBlock match

The invention discloses a pigment stirring machine for textile printing and dyeing. The pigment stirring machine comprises a stirring box, wherein the upper surface of the stirring box is fixedly connected with a transmission box matched with the stirring box; a slide groove is formed in the inner bottom wall of the transmission box; a slide block matched with the slide groove is clamped and connected inside the slide groove; a fan-shaped gear plate is put inside the stirring box; the upper surface of the slide block is provided with gear teeth matched with the gear plate; the outer surface ofthe gear plate is engaged with the gear teeth; a first passage is formed in the middle part of the upper surface of the transmission box. The pigment stirring machine for textile printing and dyeinghas the advantages that through the arrangement of a stirring motor, under the effect of a stirring shaft and a stirring rod, pigments in the stirring box can be stirred; through the arrangement of anelectric push rod and under the effects of a transmission rod, the gear plate, the slide block and a connecting rod, the stirring motor, the stirring shaft and the stirring rod can move leftwards andrightwards, so that the pigments in the stirring box can be longitudinally stirred; meanwhile, the transverse mixing can also be realized; the goal of sufficiently mixing and uniformly stirring the pigments in the stirring box can be achieved.

Owner:李培培

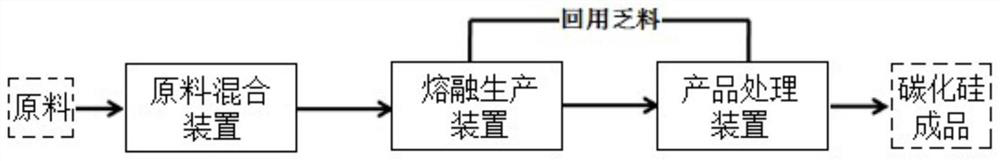

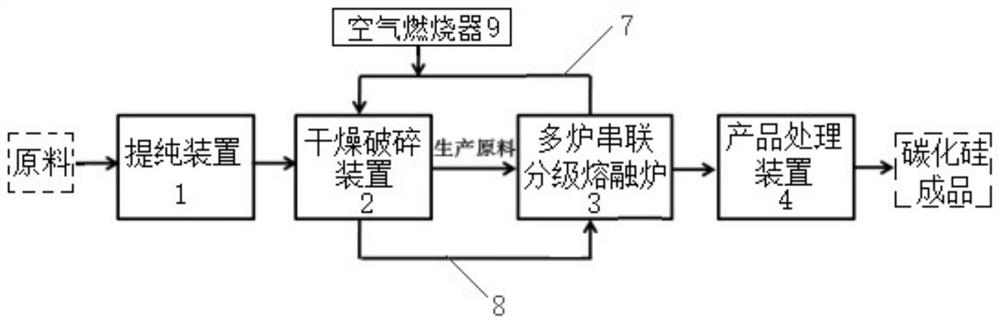

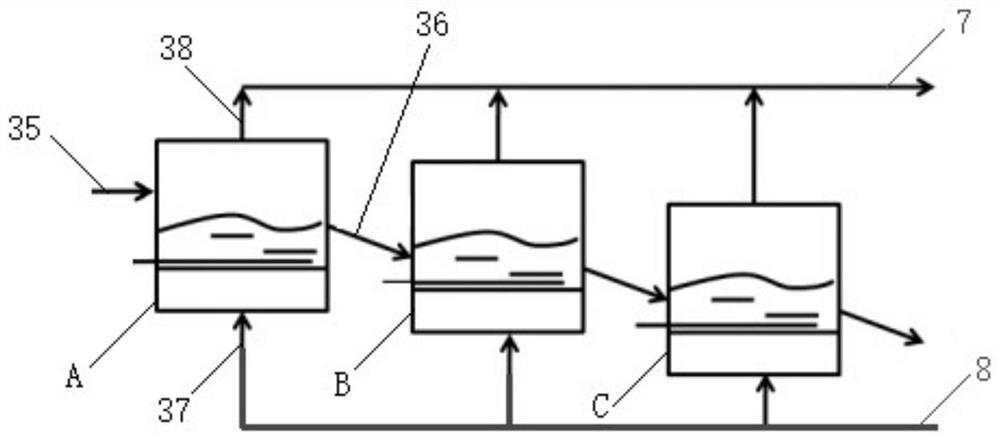

Method for producing silicon carbide by adopting multi-furnace series staged melting furnace and special production system

ActiveCN112923733AImprove responseImprove continuityChemical industryMaintainance of heating chambersCarbide siliconLiquid state

The invention discloses a method for producing silicon carbide by adopting a multi-furnace series staged melting furnace and a special production system. The system comprises the following steps that a liquid raw material is purified, dried and crushed, then sequentially passes through a single bed layer of each stage of furnace body in the multi-furnace single-layer series staged melting furnace, and is gradually molten to a liquid state for a melting reaction to generate silicon carbide. The invention further discloses the special production system based on the multi-furnace series staged melting furnace, and each stage of melting furnace is only provided with one bed layer for a fluidized melting reaction. According to the method, the liquid raw material easy to purify is adopted, a staged melting production mode of the multi-furnace series staged melting furnace is applied, a temperature of a furnace layer is accurately controlled by utilizing a graphite heating core so as to control a product type, inert gas is used as fluidizing gas to generate turbulence in a molten material of the bed layers, a continuous silicon carbide production process is realized, the product stability is ensured, the reaction time is shortened to 1-2 hours, the production efficiency is greatly improved, the effective recycling of energy is realized, and the energy consumption and the production cost are reduced.

Owner:北京绿清科技有限公司

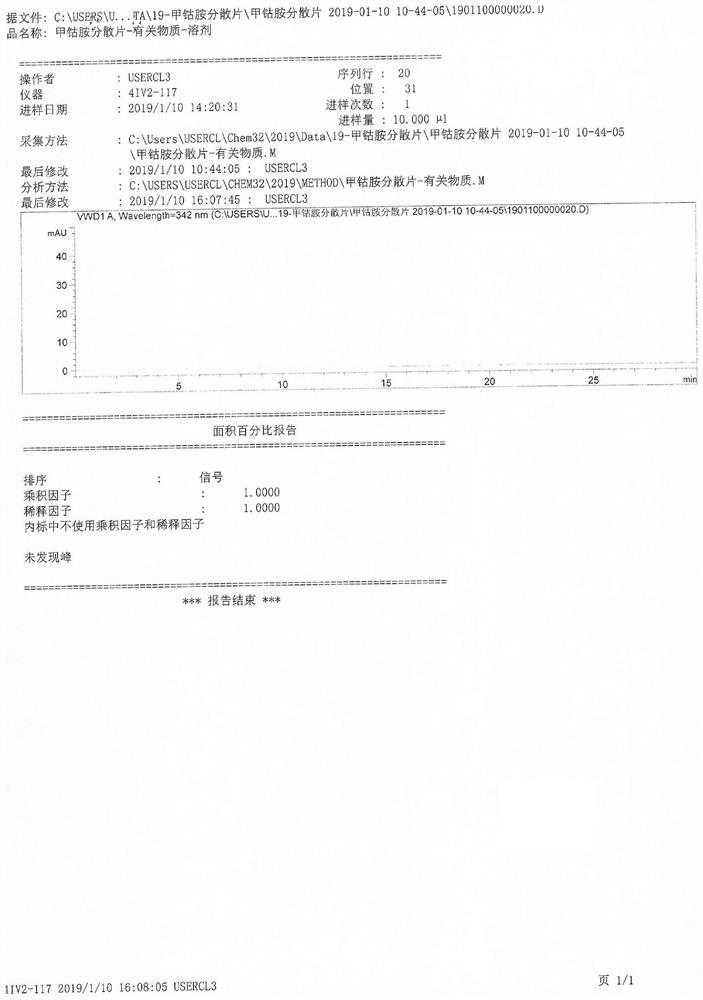

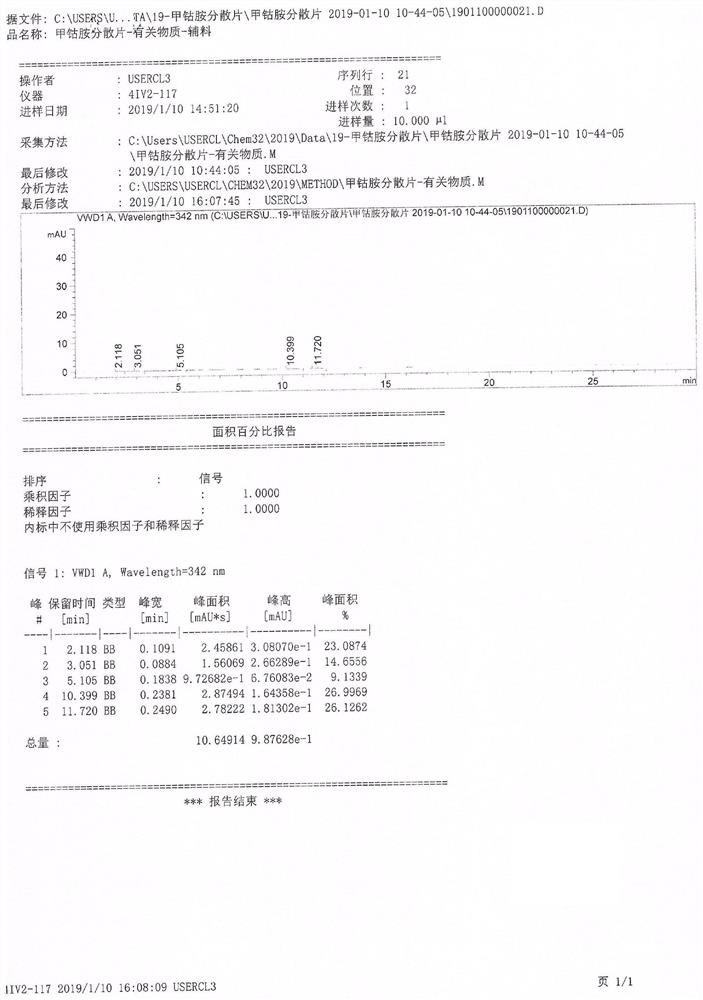

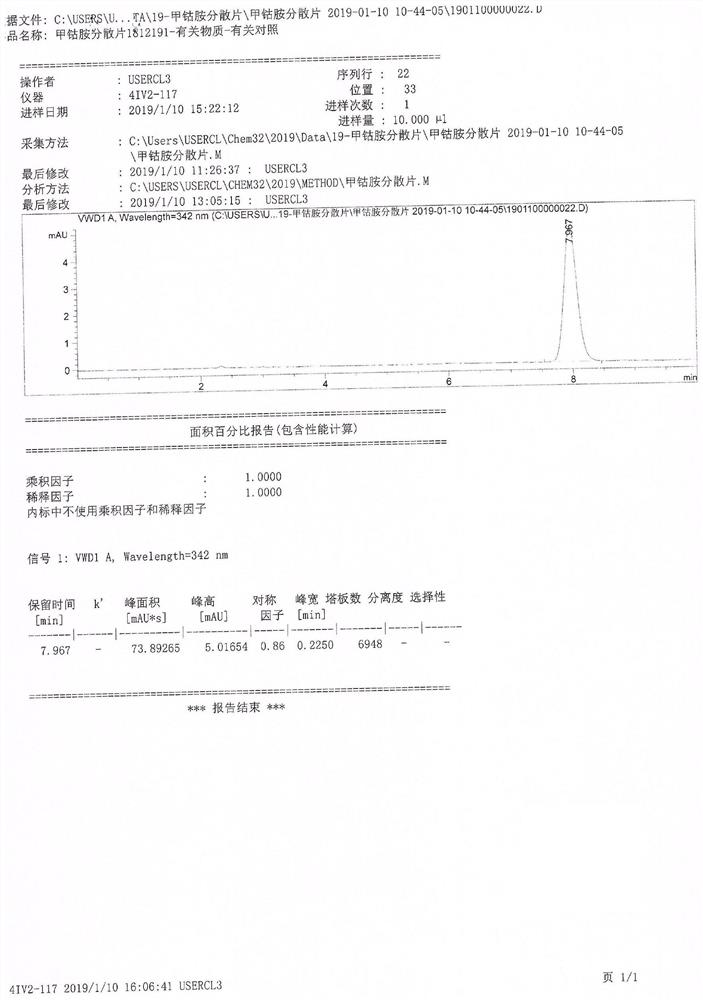

Preparation method of mecobalamin dispersible tablets

PendingCN111743870AShort process routeIncrease productivityOrganic active ingredientsNervous disorderSodium carboxymethylcelluloseLactose

The invention provides a preparation method of mecobalamin dispersible tablets, which comprises the following steps: adding a part of microcrystalline cellulose into a three-dimensional mixer, addinga mecobalamin raw material, and mixing to obtain a mixture I; rinsing the tank body of the three-dimensional mixer with lactose, adding the rinsed lactose and the mixture I into the multi-dimensionalmixer, adding croscarmellose sodium and the other part of microcrystalline cellulose into the multi-dimensional mixer, and mixing to obtain a mixture II. The invention provides a preparation method ofmecobalamin dispersible tablets. A direct tabletting method is adopted; links such as granulation, size stabilization and drying are omitted; the method has the characteristics of short process route, high production efficiency, low energy consumption and few degradation impurities; the materials are fully and uniformly mixed by three steps, the mecobalamin raw material can be uniformly distributed in the dispersible tablet, and the obtained mecobalamin dispersible tablet has much lower impurity content and higher purity than the mecobalamin dispersible tablet prepared by the existing wet granulation process.

Owner:ZHUOHE PHARM GRP CO LTD

Milk powder capable of protecting eyes and relieving visual fatigue, preparation method and preparation device

ActiveCN111758785ANutritional balanceQuality improvementMilk preparationMuscular asthenopiaProtecting eye

The invention relates to the technical field of milk powder production, specifically to milk powder capable of protecting eyes and relieving asthenopia, a preparation method and a preparation device.The milk powder is prepared from the following raw materials in parts by weight: 360-480 parts of fresh milk, 40-60 parts of fruit and vegetable powder capable of relieving visual fatigue, 16-22 partsof functional eye-protecting and brain-benefiting powder, 6-12 parts of a composite additive, 2-4 parts of composite vitamins and 2-3 parts of composite probiotics. The whole preparation device comprises a fresh milk preheating sterilization box, a highly-efficient vacuum material mixing tank, a milk powder mixed liquid filtering tank, a milk powder homogenizer, an evaporation concentrator and aspray dryer. According to the milk powder disclosed by the invention, through mutual coordination effects of carrot powder, black fungus powder, spinach powder, blueberry powder, Chinese wolfberry powder and chrysanthemum powder, an excellent treatment effect on eyes of a user can be achieved; the problems caused by long-term use of electronic products like computers by people suffering from eye diseases are effectively relieved; and the blank of milk powder helpful for eyes in the market is filled.

Owner:湖南四季南山营养食品有限公司

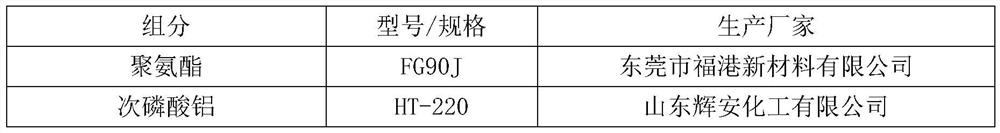

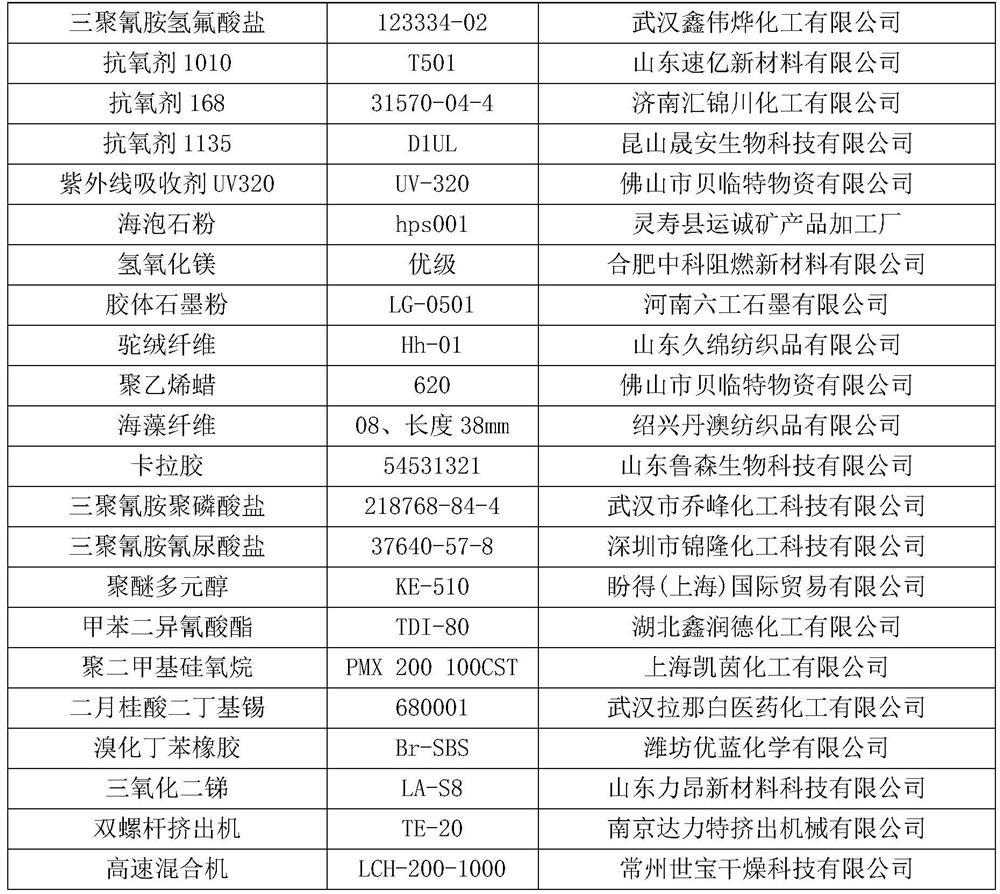

Electric wire material and preparation method thereof

The invention relates to the technical field of cables, and particularly discloses an electric wire material and a preparation method thereof. The electric wire material is prepared from the following raw materials in parts by weight: 50-80 parts of polyurethane, 10-16 parts of aluminum hypophosphite, 10-20 parts of melamine salt, 2-4.5 parts of polyurethane-organic silicon polymerized master batch, 0.2-1 part of an antioxidant, 0.1-1 part of an ultraviolet light absorber and 5-10 parts of a flame retardant, wherein the polyurethane is polyether type thermoplastic polyurethane, and the flame retardant comprises at least one of sepiolite powder, magnesium hydroxide and colloidal graphite powder. The preparation method of the electric wire material comprises the following steps: uniformly mixing aluminum hypophosphite, melamine salt and the flame retardant, mixing with polyurethane, the antioxidant, the ultraviolet light absorber and the polyurethane-organic silicon polymer master batch, uniformly mixing, carrying out melt extrusion, controlling the temperature at 140-190 DEG C, and pelletizing to obtain the electric wire material. The electric wire material has the advantage of small friction coefficient.

Owner:杭州卓时新材料有限公司

Wear-resistant self-priming pump liner prepared based on fluorine plastics

The invention discloses a wear-resistant self-priming pump liner prepared based on fluorine plastics, and relates to the technical field of pump valve preparation. The wear-resistant self-priming pumpliner is prepared from, by weight, 80-82 parts of polytetrafluoroethylene, 60-62 parts of polyperfluoro-ethylene propylene, 15-25 parts of phenolic resin, 6-8 parts of molybdenum disulfide, 3-5 partsof carbon black, 8-10 parts of titanium dioxide, 2-4 parts of Mohr's salt, 3-5 parts of barium sulfate, 5-7 parts of magnesium hexasilicate, 3-5 parts of brown aluminum oxide, 3-5 parts of nano-silicon carbide, 6-8 parts of nano-zinc oxide, 2-4 parts of boron oxide, 6-8 parts of glass fibers and 40-50 parts of high-strength mixed adhesives. The wear-resistant self-priming pump liner has the advantages that the technological process is simple, raw material ratio is reasonable, raw materials are inexpensive and easy to obtain, the liner has better wear-resistant effects while the anticorrosionperformance of a traditional fluorine plastic is ensured, and the liner is low in price and simple to process.

Owner:慈溪市得鑫五金配件有限公司

A kind of preparation method of microbial spore dry suspension agent

ActiveCN104830688BMix thoroughly mix wellReduce mortalityMicroorganism preservationMicroorganismSpore

The invention relates to a preparation method of a microbial brood-gemma dry suspending agent. According to the method, when a carrier is mixed with a concentrated microbial brood-gemma liquid, the concentrated microbial brood-gemma liquid is directly sprayed onto the carrier at a low-temperature of 30-35DEG C, so that the concentrated microbial brood-gemma liquid can be fully and uniformly mixed with the carrier, and the water content of the mixture of the concentrated microbial brood-gemma liquid and the carrier is low. Compared with the prior art, the method has the advantages as follows: water in the mixture to be dried is reduced by about 90% so that the drying time is greatly saved; the mixture can be directly dried to meet a standard by air at 30-40DEG C during a granulation process, and since the temperature is close to a microbial fermentation temperature, the mortality of living bacteria is greatly reduced during the drying process and the product is enabled to keep high activity; primary processing and secondary processing in the prior art are combined into one, so that the method is simple and can be used for effectively improving the production efficiency.

Owner:NINGBO JIANGDONG HUIZE BIOLOGICAL TECH CO LTD

Pneumatic sprayer for fruit tree planting

InactiveCN108432728AAvoid bumpingWell mixedTransportation and packagingRotary stirring mixersFruit treeAgricultural engineering

The present invention discloses a pneumatic sprayer for fruit tree planting, which comprises a main body and a damping base. A push rod and a control panel are arranged on the left side of the main body. A mixing box and an installation box are arranged in the main body. A second motor is fixedly mounted at the internal top of the mixing box. A water pump, an air blower and a first motor are arranged in the installation box. A fixed plate arranged at the top of the main body, the water pump and an output end of the air blower are connected to a sprinkler connecting rod. A right end of the sprinkler connecting rod is fixedly connected to a sprinkler. A lower end face of the main body is fixedly connected to the damping base. A support pillar is fixedly mounted on the lower end face of the damping base and a universal wheel is arranged on the lower end face of the support pillar. The pneumatic sprayer for fruit tree planting is simple in structure and convenient to use, and can be movedconveniently. The pneumatic sprayer is capable of fully mixing added pesticide and water and fanning out the pesticide, and thus has the advantages of large spraying area, convenience of use, and highefficiency.

Owner:LIUZHOU SHENGSHI PLANTATION FIELD

Suspension insulator and preparation method thereof

InactiveCN111646779AImprove structural strengthExtended service lifeClaywaresPyrrolidinonesKaolin clay

The invention discloses a suspension insulator and relates to the technical field of insulators. The suspension insulator is prepared from the following raw materials in parts by weight: 22-30 parts of Kaolin, 16-24 parts of vermiculite, 10-18 parts of allophane, 0.5-1.5 part of sepiolite fiber, 0.5-1 parts of lignin fiber, 1-3 part of polypropylene fiber, 10-16 parts of natural zeolite powder, 12-20 parts of mica powder, 5-15 parts of barite powder, 20-30 parts of nacrite, 10-20 parts of bailai stone, 5-10 parts of zircon sand, 1-7 parts of polyvinylpyrrolidone, 1-3 parts of chromium sesquioxide, 1-3 parts of boron oxide, 1-3 parts of polyacrylic acid ethyl ester and 1-4 parts of vinyltriethoxysilane. The invention further discloses a preparation method of the insulator. The invention hasthe beneficial effects that the raw materials are reasonably matched, and a proper preparation method is adopted, so that the structural strength and breaking strength of the insulator are improved,and the service life of the insulator is prolonged.

Owner:萍乡欧姆绝缘子有限公司

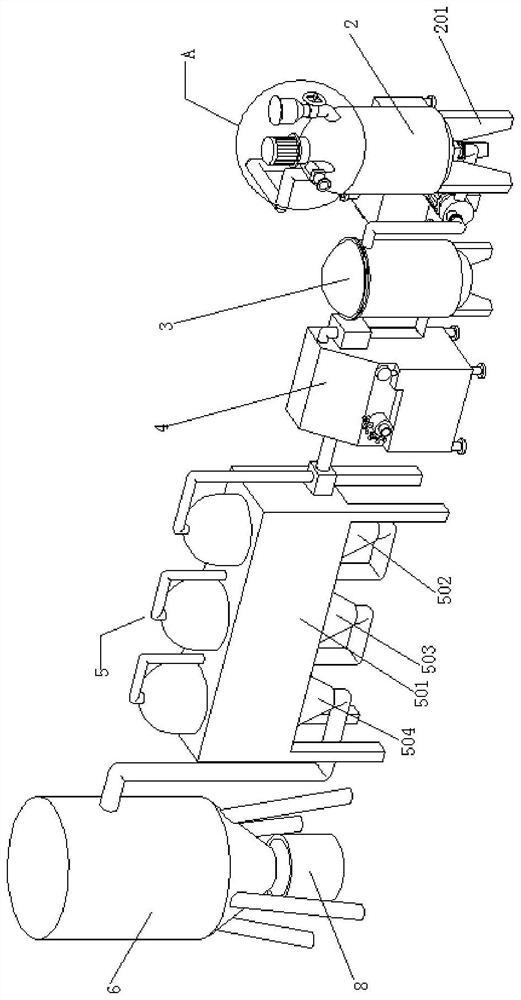

A Soil Automatic Restoration Equipment for Soil Pollution Control

ActiveCN108637002BImprove governance effectWell mixedContaminated soil reclamationGrain treatmentsChemical storageSoil science

The invention discloses automatic soil repairing equipment for soil pollution treatment. The automatic soil repairing equipment comprises a machine body, a pulverizing cavity, a liquid chemical spraying cavity and liquid chemical mixing cavities. The upper portion of the left side of the machine body is provided with a feeding port, the lower portion of the feeding port is connected with the pulverizing cavity, and the liquid chemical mixing cavities are symmetrically welded to the two sides of the pulverizing cavity. The upper side of each liquid chemical mixing cavity is fixedly provided with a liquid chemical storage cavity, wherein the liquid chemical storage cavity is connected with the liquid chemical mixing cavity through a first liquid chemical guide pipe. The liquid chemical spraying cavity is formed below the pulverizing cavity and internally provided with a grinding plate. A discharging port is formed in the left side position of the bottom of the liquid chemical spraying cavity. The automatic soil repairing equipment has the beneficial effects that efficiency is high, and energy consumption is low; workers are prevented from making direct contact with polluted soil, andlife safety and health of maintenance personnel are guaranteed; and meanwhile, manual operation is not needed in the soil treatment process, the whole treatment work process is automatic, and the burden of the workers is relieved.

Owner:CHINA CONSTR FIRST BUREAU GRP INTERIOR FITOUT ENG

LED white ceramic base flow-casting sizing agent

The invention relates to an LED white ceramic base flow-casting sizing agent. The flow-casting sizing agent comprises a powder system and a solvent system in a weight ratio of (2 to 1)-(5 to 2), wherein the powder system contains the following components in percentage by weight: 93%-95% of aluminum oxide, 2%-3% of kaolin, 2.5%-3.5% of talcum powder, 0.1%-1% of calcium carbonate and 0.1%-0.5% of lanthanum oxide; and the solvent contains the following components in percentage by weight: 75%-80% of a solvent, 10%-15% of a binder, 2.5%-3.5% of a dispersing agent and 5%-10% of a plasticizer, and the solvent is absolute ethyl alcohol. By utilizing absolute ethyl alcohol as the solvent, environmental pollution and the harm caused to a human body are avoided, and the environmental protection property and safety performance of the flow-casting sizing agent are improved.

Owner:郑州联冠科技有限公司

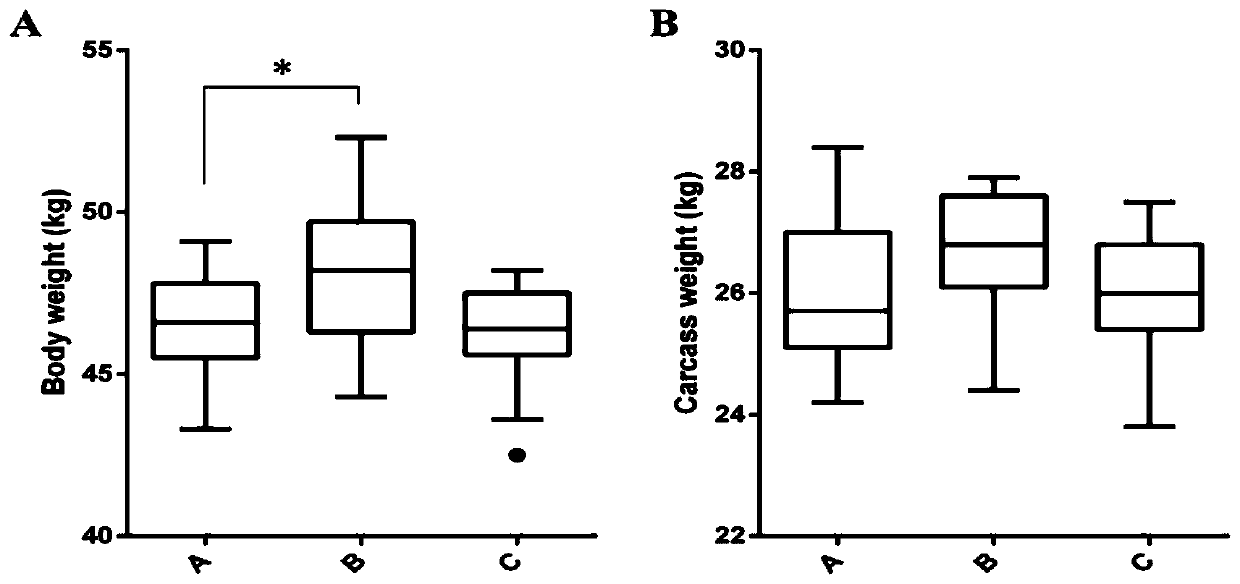

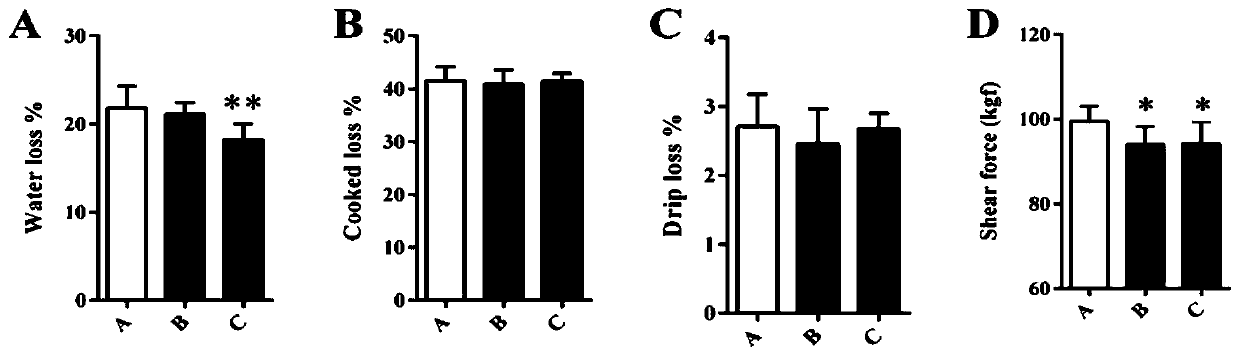

Feed formula capable of improving sheep mutton quality and use method thereof

PendingCN110074267AImprove immunityImprove intestinal environmentFood processingAnimal feeding stuffSodium bicarbonateFood additive

The invention discloses a feed formula capable of improving sheep mutton quality and a use method thereof. The feed formula includes raw materials, accessory materials and feed additives. The raw materials include the following components in percentage by mass: 40-70% of corn, 10-20% of barley straw, 5-10% of cottonseed meal, 5-10% of soybean meal, 2-8% of molasses, 0.3-0.6% of chestnut tannin, 1-2% of the accessory materials and 2-5% of the feed additives. The mass ratio of the accessory materials is 0.5-1% of expansion urea and 0.5-1% of bentonite; the mass ratio of the feed additives is 0.5-1.5% of sodium bicarbonate, 0.5-1.5% of mountain flour, 0.5-1% of pre-mixture and 0.5-1% of table salt. At the same time, a preparation method is provided: the raw materials are pulverized; early-stage treatment is performed; later-stage preparation is performed; packaging and storage are performed; and feed is used. The feed formula and the use method thereof have the beneficial effects of extremely remarkably reducing water loss rate and drip loss of meat quality through the addition of the chestnut tannin, improving well-done meat rate, improving antioxidant level of mutton, prolonging shelf period, and thus improving sheep mutton quality.

Owner:LANZHOU UNIVERSITY

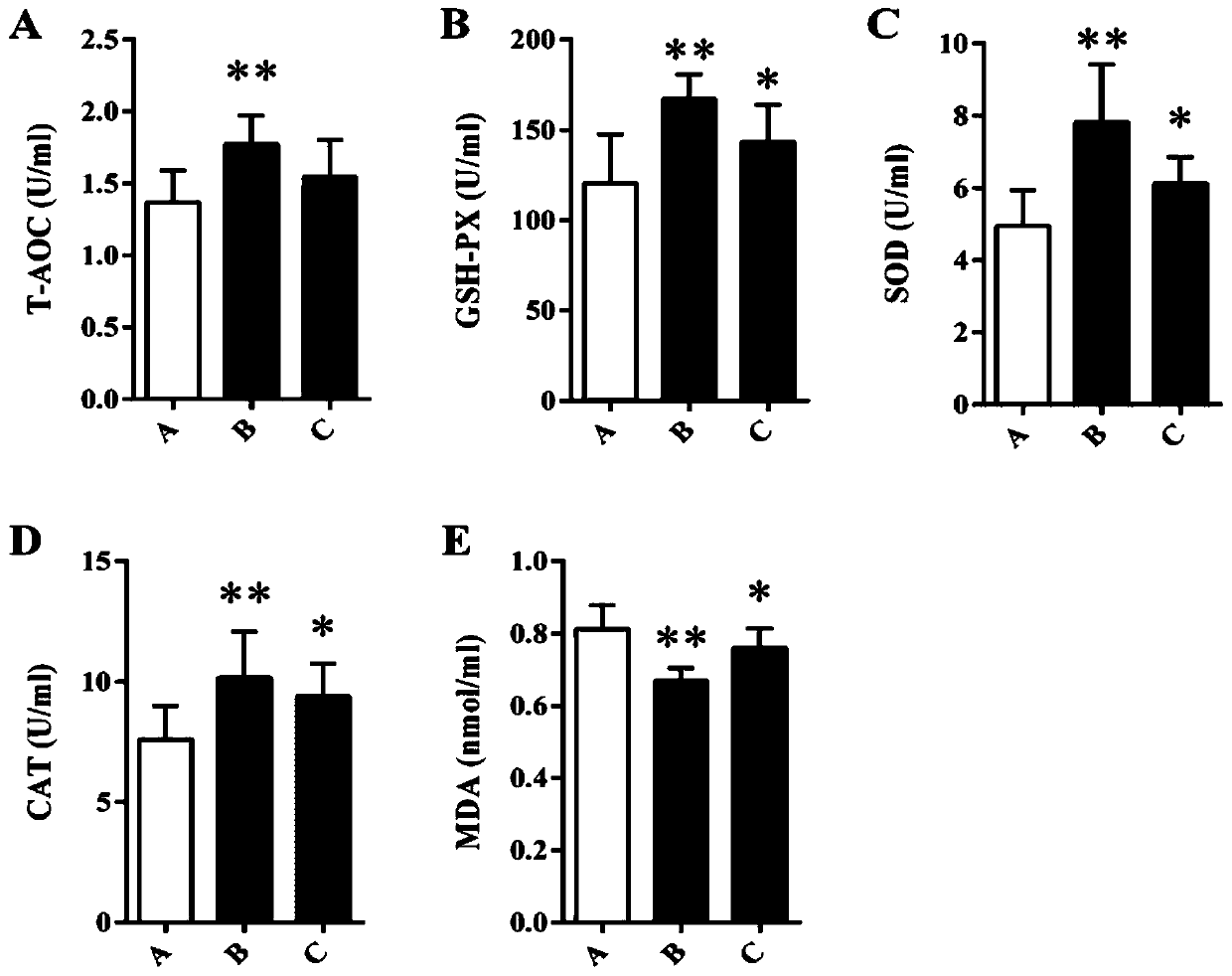

Denitration system for cement production

InactiveCN107349770AReduce burnReduce production processDispersed particle separationCyclonePulp and paper industry

The invention discloses a denitration system for cement production. The denitration system comprises a raw material preheater, a cyclone feeder, a cyclone mixer, a reductant atomizer, a reductant and atomizing agent pressurizer and a combustion furnace. The cyclone feeder is fixedly connected with a material outlet of the raw material preheater, a material outlet of the cyclone feeder is communicated with one side of the cyclone mixer, and the other side of the cyclone mixer is communicated with the reductant and atomizing agent pressurizer; the reductant and atomizing agent pressurizer is communicated with a material outlet of the reductant atomizer, the lower portion of the reductant and atomizing agent pressurizer is communicated with the combustion furnace, the lower portion of the reductant atomizer is communicated with the combustion furnace, and the lower portion of the cyclone mixer is communicated with the upper portion of the combustion furnace. The denitration system has the advantages that the waste heat of the combustion furnace can be fully utilized, and less nitric oxide is generated in the combustion process.

Owner:高建华

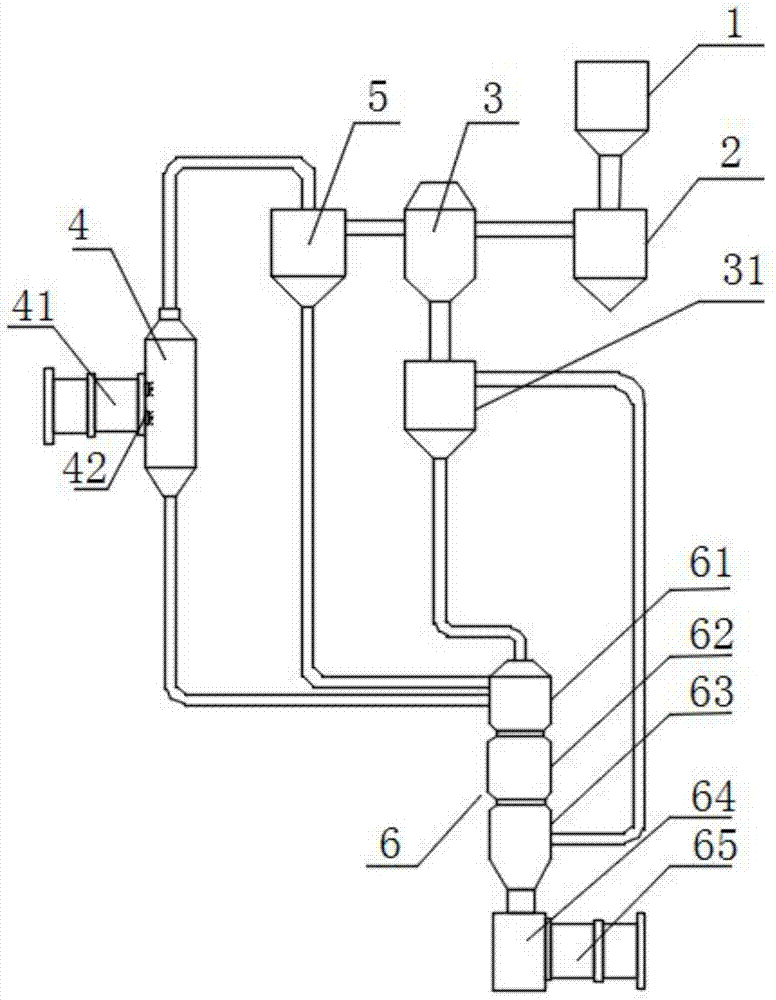

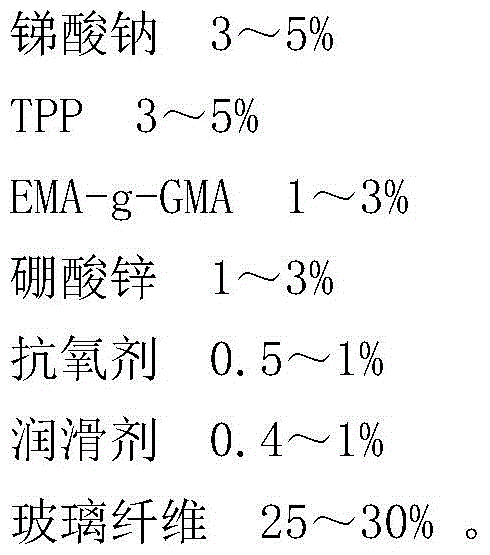

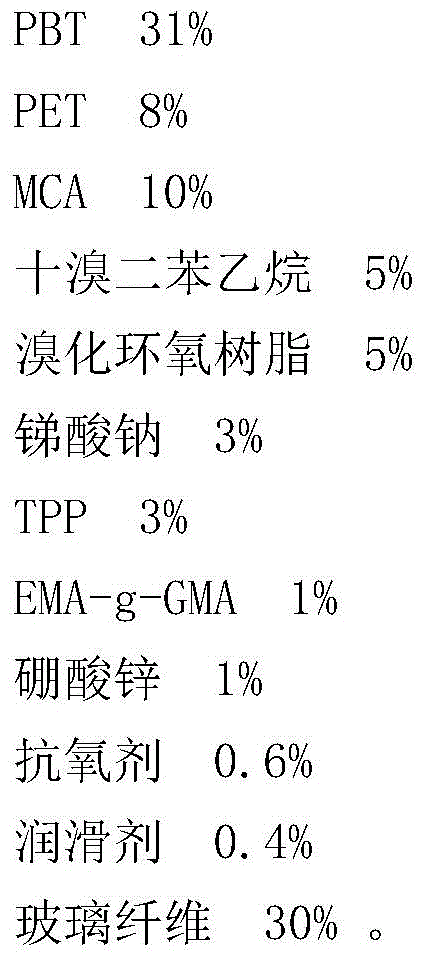

A kind of 850 degree glow wire incombustible flame-retardant reinforced PBT plastic and preparation method thereof

The invention discloses flame-retardant reinforced PBT (polybutylene terephthalate) plastic meeting the requirement for incombustibility of a glow wire at the temperature of 850 DEG C. The plastic comprises the following components in percentage by weight: 25-35% of PBT, 5-10% of PET (polyethylene terephthalate), 5-10% of MCA (methyl cyanoacrylate), 5-8% of decabromodiphenyl ethane, 5-8% of brominated epoxy resin, 3-5% of sodium antimonite, 3-5% of TPP (triphenyl phosphate), 1-3% of EMA-g-GMA, 1-3% of zinc borate, 0.5-1% of antioxidants, 0.4-1% of lubricants and 25-30% of glass fiber. The PBT plastic is prepared from multiple flame retardants in a compounding mode, the flame-retardant efficiency is improved, the use quantity of the flame retardants is reduced, the flame retardance and the mechanical performance are both considered, the requirement that the glow wire does not combust at the temperature of 850 DEG C can be met, the requirement for the mechanical performance is also met and the PBT plastic is suitable for practical use.

Owner:GUANGDONG SHUNDE SHUNYAN NEW MATERIALS

Industrial land soil ecological restoration device and use method thereof

InactiveCN113664031AAchieve loose soilAchieve flatteningContaminated soil reclamationEnvironmental resource managementGear wheel

The invention discloses an industrial land soil ecological restoration device and a use method thereof. The industrial land soil ecological restoration device comprises a mounting frame, wherein a lifting frame is arranged in the mounting frame, first air cylinders are symmetrically and fixedly connected to the top of the mounting frame, the output ends of the first air cylinders are fixedly connected with the top of the lifting frame, a first rotating shaft is rotationally connected to the interior of the lifting frame, a cutter blade is arranged on the outer side of the first rotating shaft, and a mounting plate is arranged in the mounting frame. According to the invention, by arranging the first air cylinder, the cutter blade and the first motor, soil loosening is achieved, and liquid medicine is conveniently sprayed into the soil; by arranging the water pump and the spray head, the liquid medicine spraying on the soil is achieved; the soil is conveniently bulldozed by arranging the push plate; the stirring box, the inner box and the stirring rod are arranged, so that liquid medicine is fully mixed, stirred and mixed evenly; and the second spray head, the half gear and the second air cylinder are arranged, so that the liquid medicine is sprayed on the flattened soil again, the soil is made to make full contact with the liquid medicine, and the soil is comprehensively repaired.

Owner:中科深兰(福建)环境科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com