Method for producing silicon carbide by adopting multi-furnace series staged melting furnace and special production system

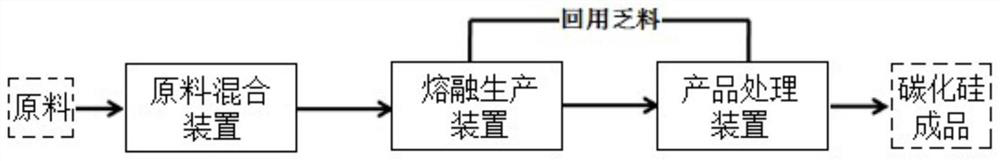

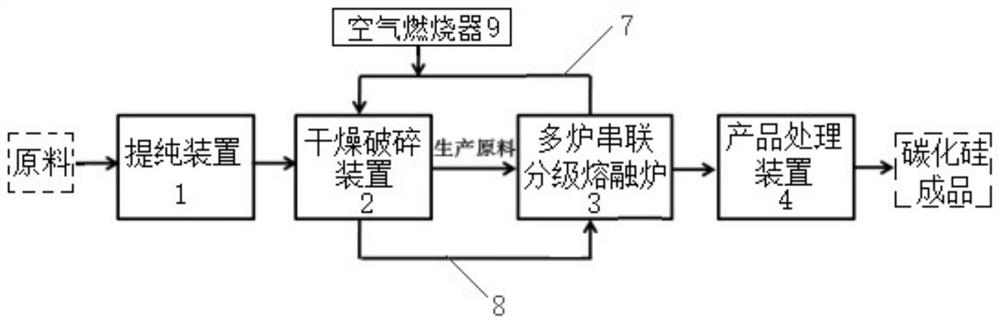

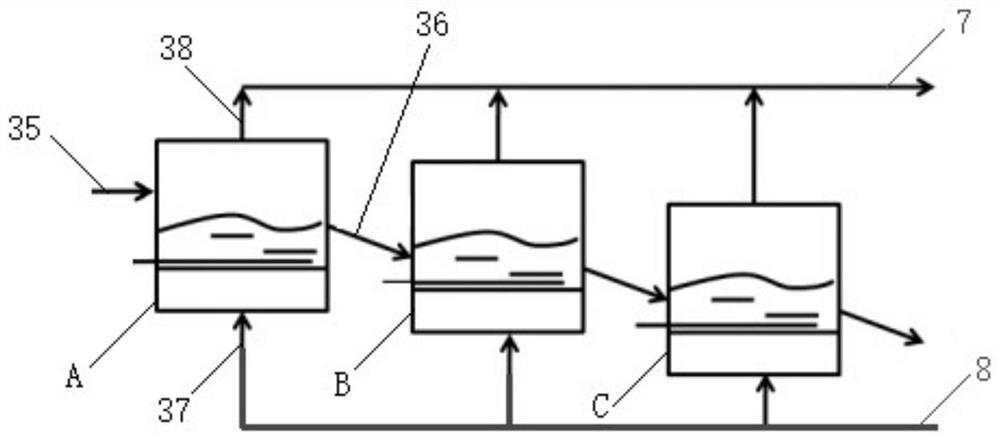

A production method and technology of silicon carbide, applied in the maintenance of furnaces, furnace components, heating chambers, etc., can solve the problems of low single-pass conversion efficiency of materials, continuous separation and reuse of product waste materials, uneven mass transfer and heat transfer, etc. Achieve effective reuse, achieve continuity, and improve conversion rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Embodiment 1 The method for producing silicon carbide based on the silicon carbide production system of multi-furnace single-layer fluidized melting furnace

[0073] Purify liquid silicon dioxide and water-soluble starch through membrane filtration equipment at room temperature to obtain high-purity raw materials. Mix the purified liquid silicon dioxide, water-soluble starch, wood chips and salt evenly (liquid silicon dioxide and water-soluble starch) The molar ratio of starch is 1:1, the weight of wood chips accounts for 2%-6% of the weight of the total raw materials (silicon source + carbon source + auxiliary materials), and the weight of table salt accounts for 3% of the weight of the total raw materials (silicon source + carbon source + auxiliary materials) -11%) obtain liquid mixed raw material;

[0074] In the drying and crushing device B, the purified liquid mixed raw material and the high-temperature inert gas (mainly Ar gas) at a temperature of 1900-2700°C are ...

Embodiment 2

[0076] The β-SiC products produced in molten state are cooled in a product processing device with cooling function and then packaged for finished products. The produced product is a fine powder β-SiC crystal of about 5 to 8 nanometers, the crystal purity is above 99.9%, and the raw material conversion rate of the whole silicon carbide production process is above 99%. Embodiment 2 The method for producing silicon carbide based on the silicon carbide production system of multi-furnace single-layer fluidized melting furnace

[0077] Purify liquid silica sol and sucrose through membrane filtration equipment at room temperature to obtain high-purity raw materials, and mix the purified liquid silica sol, sucrose, wood chips and salt evenly (the molar ratio of liquid silica sol to sucrose is 1:2, The weight of sawdust accounts for 2%-6% of the weight of the total raw material (silicon source+carbon source+auxiliary material), and the weight of table salt accounts for 3%-11% of the we...

Embodiment 3

[0081] Embodiment 3 Method for producing silicon carbide based on the silicon carbide production system of multi-furnace single-layer fluidized melting furnace

[0082] Purify liquid silicic acid and maltose through membrane filtration equipment at room temperature to obtain high-purity raw materials, and mix the purified liquid silicic acid, maltose, wood chips and salt evenly (the molar ratio of liquid silicic acid to maltose is 1:4 , the weight of sawdust accounts for 2%-6% of the total raw material (silicon source+carbon source+auxiliary material) weight, and the weight of table salt accounts for 3%-11% of the total raw material (silicon source+carbon source+auxiliary material) weight) to obtain liquid mixed raw materials ;

[0083] In the drying and crushing device B, the purified liquid mixed raw material and the high-temperature inert gas (mainly Ar gas) at a temperature of 1900-2700°C are subjected to counter-current or co-current drying to dry the purified liquid raw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com