Electric wire material and preparation method thereof

A wire material and raw material technology, applied in the field of wire material and its preparation, can solve the problems of large friction coefficient, poor compatibility, rough surface, etc., and achieve the effects of reducing friction coefficient, good lubrication, enhancing flame retardancy and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

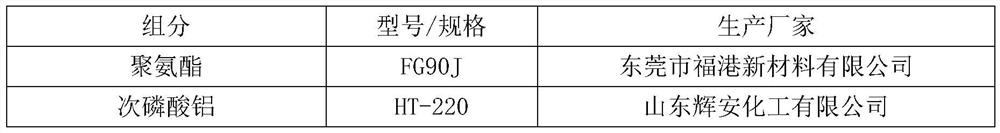

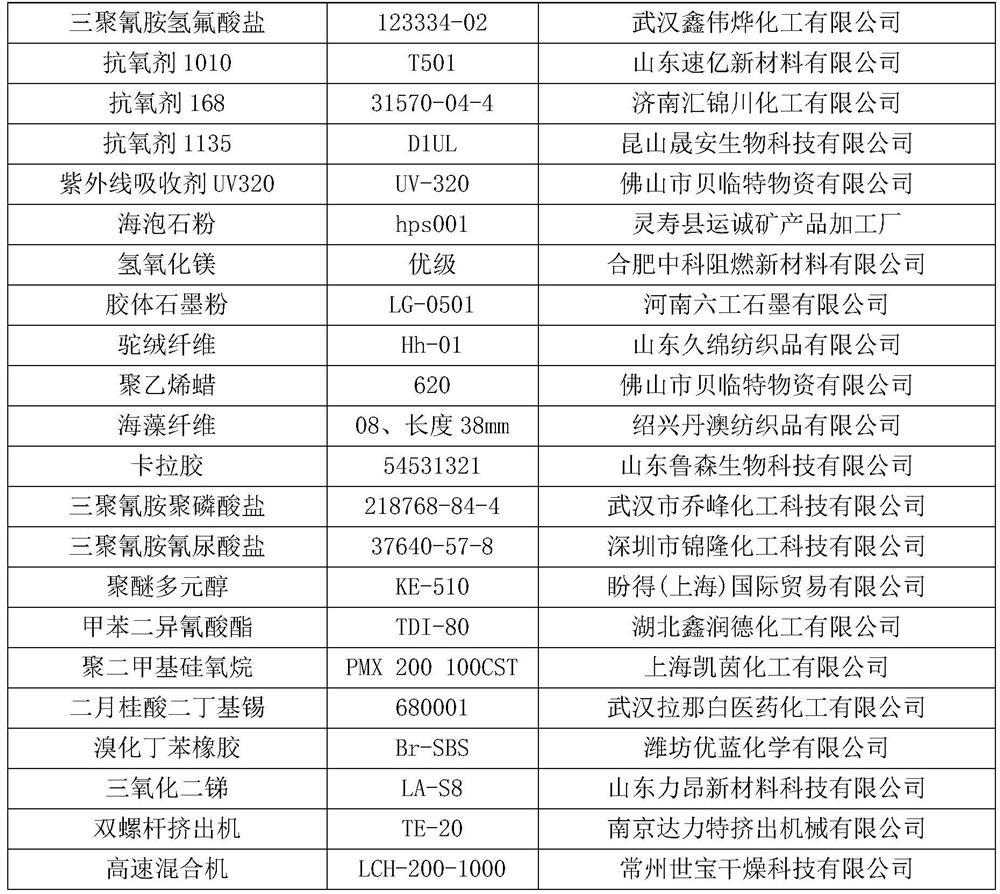

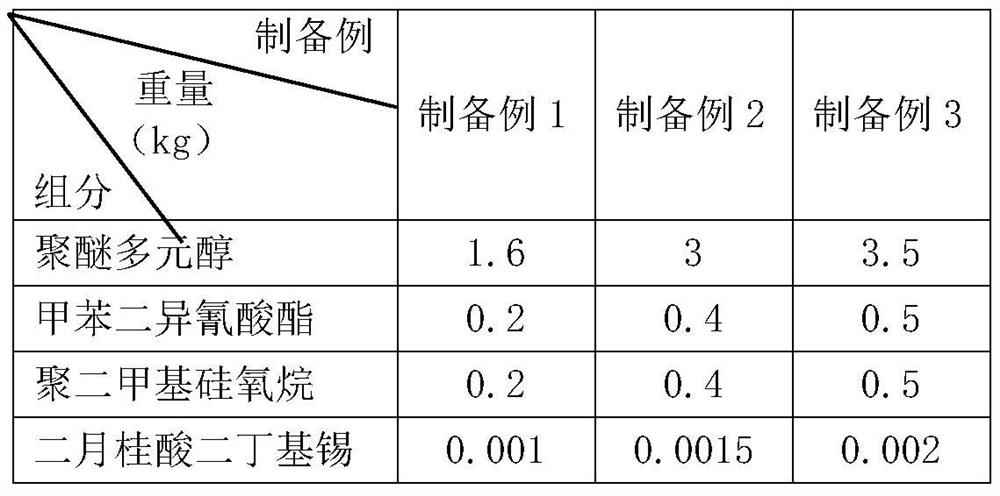

[0057] Preparation example 1: a kind of polyurethane-organic silicon polymer masterbatch, the concrete component that comprises and weight are as shown in table 2, and its preparation method is as follows:

[0058] A1: At a temperature of 50°C, mix polyether polyol and toluene diisocyanate, under the protection of nitrogen, carry out a stirring reaction, and prepare a polyurethane prepolymer after 4 hours;

[0059] A2: At a temperature of 100°C, mix the polydimethylsiloxane, the catalyst and the polyurethane prepolymer evenly, and carry out a stirring reaction under the protection of nitrogen; after 4 hours, a polyurethane-organic silicon copolymer is obtained;

[0060] A3: Melt and extrude the polyurethane-organic silicon copolymer in a twin-screw extruder, control the temperature of each section to 100-110-120-140-150°C, the speed of the screw extruder is 100r / min, and the pressure is 60MPa and cooling in a water tank for 1 hour, removing water until there is no moisture on ...

preparation example 2

[0061] Preparation example 2: a kind of polyurethane-silicone resin polymerization masterbatch, the concrete component that comprises and weight are as shown in table 2, and its preparation method is as follows:

[0062] A1: At a temperature of 60°C, mix polyether polyol and toluene diisocyanate, under the protection of nitrogen, carry out a stirring reaction, and prepare a polyurethane prepolymer after 3 hours;

[0063] A2: At a temperature of 80°C, mix the polydimethylsiloxane, the catalyst and the polyurethane prepolymer evenly, and carry out a stirring reaction under the protection of nitrogen; after 5 hours, a polyurethane-organosilicon copolymer is obtained;

[0064] A3: Melt extrude the polyurethane-silicone copolymer, control the temperature of each section to 100-110-120-140-150°C, the speed of the screw extruder is 110r / min, and the pressure is 60MPa; and cool in the water tank for 1h and pelletizing to obtain polyurethane-organic silicon polymer masterbatch.

preparation example 3

[0065] Preparation example 3: a kind of polyurethane-organic silicon resin polymer masterbatch, the difference with preparation example 1 is that the weight of components is different, and the specific components and weights included are as shown in table 2,

[0066] Concrete composition and weight of table 2 preparation example 1-3

[0067]

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com